What do you need to know

CNC Machining Basics

What Is CNC Machining?

Computer-controlled cutting and shaping of materials for precision parts.

How CNC Machines Work?

Another Simple and easy way to show your content with less gap. Grab user attention in a more productive way.

Main Types of CNC Machines

This amazing style will allow you to add your image box content slide down with Just placing your mouse over the Image box.

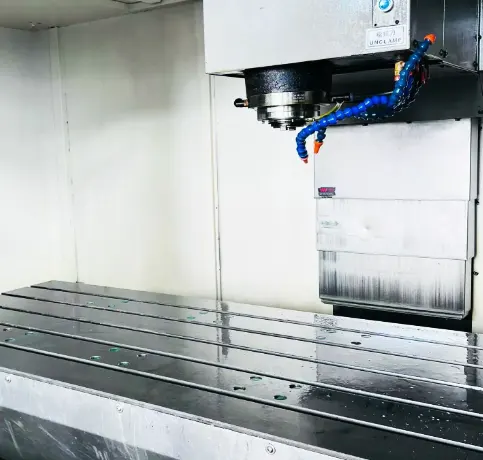

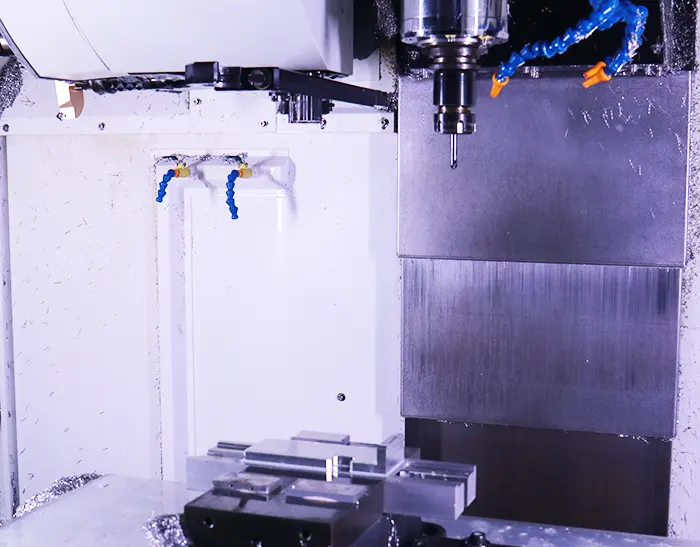

3 axis CNC Milling

4 axis CNC Milling

5-Axis Machines

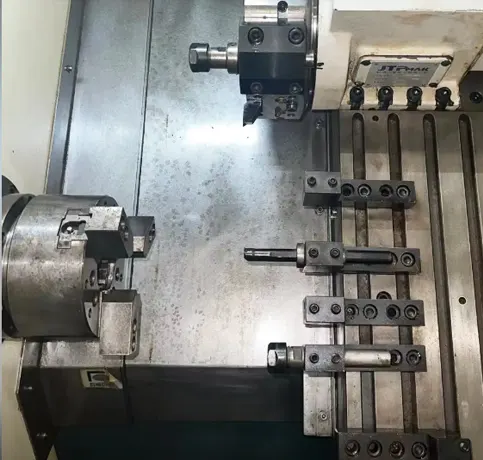

CNC Turning

Basic Components of a CNC Machine

Another Simple and easy way to show your content with less gap. Grab user attention in a more productive way.

Common CNC Machining Terms

This amazing style will allow you to add your image box content slide down with Just placing your mouse over the Image box.

| Tolerance | Chip Load | Toolpath | Zero Point | Face Mill | Reamer | Tool Offset |

| Step-Over | Step-Over | Roughing | Chip | Ball Nose End Mill | Ball Nose End Mill | Insert |

| Backlash | Climb Milling | Conventional Milling | Flutes | End Mill | Drill Bit | Threading Tool |

| Tool Wear Offset | Facing | Turning | Boring | Reaming | Knurling | Broaching |

| Tapping Cycle | Home Position | Work Coordinate System | Soft Limits | Hard Limits | Rapids | Interpolation |

| Post Processor | Subroutine | Tool Change Command | Spindle Orientation | Canned Cycle | Helical Interpolation | Cutter Compensation |

| Coordinate Measuring Machine | Caliper | Micrometer | GD&T | Runout | Concentricity | Flatness |

| Hardness (HRC) | Tool Steel | Coolant Mist | Heat Affected Zone (HAZ) | Ball Screw | Linear Guideways | ATC (Automatic Tool Changer) |

Types of Machining Operations

Welcome to this zone, where we share some common manufacturing knowledge or technical issue.

Hole-Related Machining

Time has changed

- Drilling

- Boring

- Reaming

- Countersinking

- Counterboring

- Tapping

- Thread Milling

- Gun Drilling / Deep Hole Drilling

Surface and Contour Machining

Time has changed

- Face Milling

- Profile Milling

- Pocket Milling

- Slot Milling

- Surface Grinding

- Planing

Thin-Wall & Precision Feature Machining

Time has changed

- Thin-Wall Machining

- Micro-Machining

- High-Speed Machining

- Precision Boring / Honing

Threading and Fastener Machining

Time has changed

- Thread Turning

- Thread Rolling

- Thread Grinding

- Thread Milling

Complex Geometry Machining

Time has changed

- 5-Axis Machining

- 3D Surface Machining

- Contour Turning

- Helical Milling

- Gear Cutting / Spline Machining

Finishing and Post-Machining Processes

Time has changed

- Deburring

- Polishing / Buffing

- Lapping

- Anodizing / Plating

- Laser Engraving

Special CNC Machining Processes

Time has changed

- Electrical Discharge Machining

- Wire EDM

- Ultrasonic Machining

- Waterjet Cutting

- Laser Cutting

Materials Used in CNC Machining

Another Simple and easy way to show your content with less gap. Grab user attention in a more productive way.

What Products Can CNC Machines Make?

This amazing style will allow you to add your image box content slide down with Just placing your mouse over the Image box.

Advantages of CNC Machining

Another Simple and easy way to show your content with less gap. Grab user attention in a more productive way.

Why Choose Our CNC Machining Services?

This amazing style will allow you to add your image box content slide down with Just placing your mouse over the Image box.

CNC machining (Computer Numerical Control machining) is a manufacturing process that uses computer-controlled tools to remove material from a solid block—called a workpiece—until the final shape is produced. Compared to manual machining, CNC machines follow digital instructions, allowing higher accuracy, better repeatability, and faster production.

TonzaMaking