Order your custom metal and plastic parts.

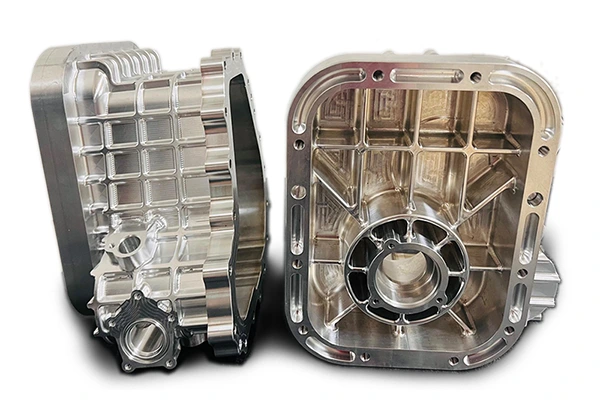

Online CNC Machining Services

Get an instant online quote for your CNC-machined metal or plastic parts, from rapid prototyping to full-scale production.

- Our in-house machine shop operates 24/7, ensuring quick turnaround times.

- Tolerances up to ±0.0004″ (0.01mm)

- Lead times as short as 1 day.

Type of CNC machining services

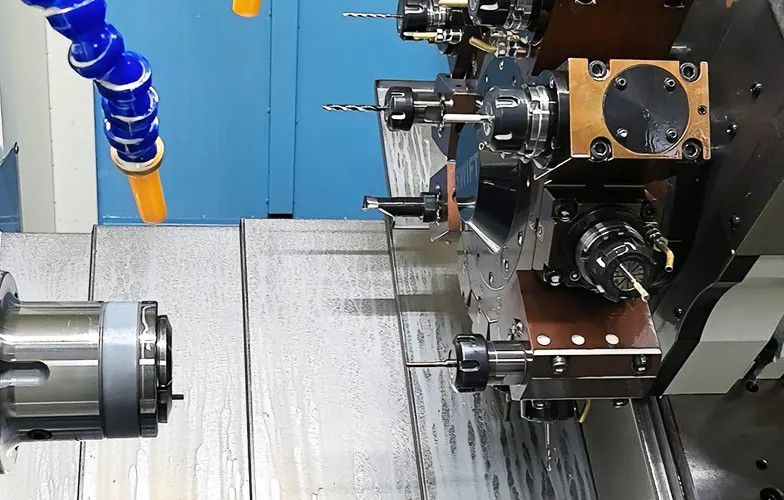

We provide comprehensive CNC machining services, including milling, turning, drilling, tapping, EDM (Electrical Discharge Machining), and wire EDM, for a variety of materials.

CNC Milling services

CNC Turnning services

5-Axis CNC Machining

Precision Machining Services

Why Choose ours CNC Machining Services?

delivering exceptional results through experience, dedication, and strategic thinking.

working closely with clients to understand their unique needs and goals

featuring the latest technology and advanced machinery to ensure precision, efficiency.

leveraging cutting-edge technology to manufacture intricate components

delivering exceptional value without compromising on quality or precision.

ensuring fast, efficient, and reliable production without compromising quality.

Capabilities of CNC Machining Services

Our CNC machines deliver precision tolerances that meet industry standards, ensuring consistent accuracy and seamless component fit.

Maximum Diameter: 500mm or 19.7-inch

Maximum Length: 1800mm or 70.9-inch

Metal: 0.5mm or 0.02 in

Plastic: 1.0mm or 0.04 in

Metal: +/- 0.005mm (+/-0.0002 in)

Plastic: +/-0.025mm(+/-0.001 in)

4 bussiness days for most projects.

simple parts can be as fast as 1 day.

Design Guidelines

Optimize your designs for manufacturability with our expert guidelines and feedback, ensuring the best results in CNC machining.

Maximize the internal radius.

Avoid excessive cavity depth, grooves, and holes.

Try you best to avoid thin walls

No small text

Standards for threads

Materials for CNC Machining

CNC technology enables the machining of a wide range of materials with precision and efficiency. At TonZa, we offer CNC machining quotes for over 30 engineering-grade plastics and metals, ensuring versatility for various applications. Additionally, a variety of surface finishes can be applied to enhance the appearance and functionality of CNC-machined parts.

Metal

Plastic

Surface Finishes

We are offering over 20 options of surface finishes to fulfill both your functional and aesthetic requirements.

Brushing

Polishing

Tumbling

Anodizing

Black Oxide

Electroplating

Powder Coating

Alodine

Passivation

Electroless Plating

CNC Machining Solutions

We offer a wide range of CNC materials for custom parts, including aluminum, steel, brass, plastics, and over 100 other materials.

| Prototype | Bridge Production | Massive Production |

|---|---|---|

| Smaller Tool Stock, More Axis | Big Tool Stock, More Axis | Bigger Tool Stock, Less Axis |

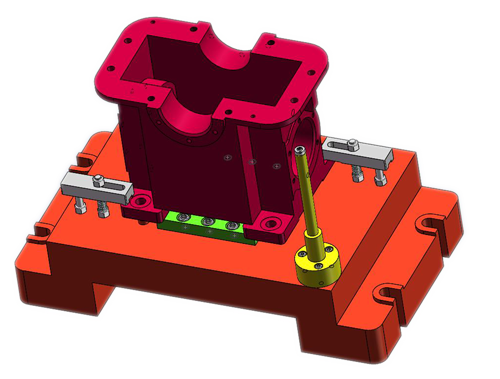

| Predominantly standard fixtures. | A few custom-made fixtures. | Custom Made Fixture |

| Highly precise with significant variance. | Highly precise with significant variance. | Accurate with slight variance. |

| Very expensive per Unit | expensive per Unit | Low per unit |

| Lead Time: 1-4 business days | Lead Time: 5-12 business days | Lead Time: 2-4 weeks |

| Capability:1-50 pcs | Capability:51-10,000 pcs | Capability:Above 10,001 pcs |

Application Industries

Optimize your designs for manufacturability with our expert guidelines and feedback, ensuring the best results in CNC machining.

FAQ

To provide clarity on our services, here are answers to frequently asked questions about prototyping and manufacturing.

What materials do you work with for CNC machining?

We work with a wide range of materials, including aluminum, stainless steel, titanium, brass, copper, plastics (POM, ABS, PEEK, etc.), and more.

What are your machining capabilities?

We provide precision CNC milling, CNC turning, 5-axis machining, EDM, wire cutting, and surface finishing to meet different industry requirements.

What industries do you serve?

We serve industries including aerospace, denfense, medical, defense, electronics, communication, industrial equipment, and consumer products.

What tolerances can you achieve?

Our CNC machining tolerances range from ±0.005mm to ±0.1mm, depending on part design and material.

Do you provide surface finishing options?

Yes, we offer anodizing, powder coating, polishing, bead blasting, electroplating, passivation, and more.

What is your standard lead time for CNC machined parts?

Our lead time varies based on complexity and quantity. Prototyping orders can take 3–7 days, while bulk production takes 2–4 weeks.

Do you provide custom prototypes?

Yes, we specialize in rapid prototyping and can produce high-precision prototypes using CNC machining, 3D printing, and other methods.

Can you handle large-volume production?

Yes, we support both low-volume and mass production with consistent quality control.

How do you ensure quality control?

We follow ISO 9001 standards, using CMM inspection, visual inspection, and in-process quality checks to guarantee precision and consistency.

How can I request a quote for CNC machining services?

You can send us drawings (STEP, IGES, or PDF), material requirements, quantities, and surface finish preferences to receive a fast quote within 24 hours.

Blog

Welcome to our blog, where we share insights into various manufacturing processes.