Plastic injection molding is a way to make plastic parts. Hot, melted plastic is pushed into a mold to shape it. This process helps create detailed designs that are accurate and consistent. It is important in today’s manufacturing because it is fast and flexible.

Polypropylene, a popular plastic, is 38% of all plastics used.

Electric machines use up to 50% less energy than hydraulic ones.

Making each part takes 15 to 30 seconds, allowing quick production.

These benefits make plastic injection molding key for cars, electronics, and everyday products.

Key Takeaways

Plastic injection molding melts plastic to make parts fast and precise.

Picking good materials and designing molds well improves quality and saves money.

The process is quick, making parts in 15 to 30 seconds.

Using green materials and machines helps the planet and works better.

This method is used in cars, healthcare, and packaging to make daily items.

What Is Plastic Injection Molding?

Definition and Overview

Plastic injection molding is a way to make plastic parts. Melted plastic is pushed into a mold to form shapes. This method has been used since the late 1800s. The Hyatt brothers made a machine in 1872 for small items like buttons. Over time, the process improved with new plastics like polypropylene and ABS, which are common today.

The process has these main steps:

Clamping: The mold is tightly closed before adding plastic.

Injection: Melted plastic is pushed into the mold.

Dwelling: The plastic is pressed to remove stress.

Cooling: The plastic hardens and keeps its shape.

Mold Opening: The mold is opened carefully.

Ejection: The finished part is taken out.

This method is fast and flexible, making it great for simple or detailed parts.

Benefits of Plastic Injection Molding

Plastic injection molding has many advantages. It is very fast, so you can make many parts quickly. It also makes parts that are the same every time, which is important for quality. For example, keeping walls the same thickness saves material and makes parts stronger.

It is also cost-friendly. Making molds costs a lot at first, but the price per part drops when making many. This is why it’s great for industries like cars and electronics. Plus, it works with many materials, like ABS for strength or polyethylene for water resistance.

Why It Is Essential in Modern Manufacturing

Plastic injection molding is very important today. It is widely used, with polypropylene making up 38% of all plastics. This shows how useful it is for many industries.

It also helps the environment. Many companies now use recyclable plastics and better designs to cut waste. This makes products useful and eco-friendly.

In today’s fast world, this process is quick, exact, and flexible. Whether for gadgets or car parts, it always makes high-quality items.

The Plastic Injection Molding Process

Material Selection and Preparation

Picking the right material is the first step. Think about strength, impact resistance, and heat tolerance. For example:

Strength helps the part stay strong under pressure.

Impact Resistance lets the material handle sudden hits without breaking.

Heat Tolerance shows how well it works in high heat.

Work with engineers to improve designs and use less material. Choose materials that balance cost and performance. Using recycled materials can make the process more eco-friendly. Good molds help avoid mistakes and speed up production.

Feeding and Melting the Plastic

After choosing the material, it goes into the machine. Plastic pellets are poured into a hopper and move to the barrel. There, they are heated and melted. Heat comes from heater bands and a spinning screw. The screw creates extra heat by moving the plastic.

Keeping the right temperature is very important. For example, polyetherimide (PEI) melts at about 490°F. If it gets too hot, it breaks down. At 700°F, PEI lasts 12 minutes, but only 6 minutes at 770°F. Controlling heat, screw speed, and time ensures good quality parts.

Injecting the Molten Plastic into the Mold

The melted plastic is pushed into the mold. Speed and pressure must be just right to avoid problems. Important factors include:

Injection Pressure: Fills the mold and affects part quality.

Nozzle Pressure: Helps the plastic flow smoothly into the mold.

Injection Speed: Affects how smooth and even the part looks. Medium parts usually need speeds of 50-100 mm/s.

The mold stays tightly closed to stop leaks. After filling, holding pressure keeps the part’s shape as it cools.

Cooling and Solidifying the Product

After the hot plastic fills the mold, it starts cooling. This step is very important because it hardens the part and keeps its shape. Cooling takes up about 70-80% of the whole molding process. A good cooling system can save money and time. Poor cooling can cause problems like bending or uneven shapes.

Here are some things that affect cooling:

Factor | What It Means |

|---|---|

Material Properties | Different plastics cool at different speeds based on their heat traits. |

Wall Thickness | Thicker parts take longer to cool because they have more material. |

Mold Material | Some mold materials, like aluminum, cool faster than others like steel. |

Cooling Channel Design | The way cooling channels are made helps remove heat better. |

Mold Temperature | A cooler mold helps the plastic cool faster and evenly. |

To make cooling better, focus on how cooling channels are designed and pick the right mold material. Good cooling saves time and makes sure the product is high quality.

Tip: Always check mold temperature and cooling channels to avoid mistakes and keep parts consistent.

Ejecting and Finishing the Final Part

When the plastic part cools and hardens, the mold opens. Then, ejector pins or plates push the part out. This step must be done carefully to avoid breaking the part. Proper ejection keeps the part’s shape and surface smooth.

Checking quality is very important here. The table below shows what to watch for:

Metric | What It Checks |

|---|---|

Dimensional Accuracy | Makes sure the part fits the design and works properly. |

Weight Consistency | Keeps the weight the same to avoid problems like empty spots. |

Cycle Time | Tracks how long it takes to finish one molding process. |

Appearance and Surface Finish | Checks for a smooth surface without marks or lines. |

Material Integrity | Tests the material to make sure it is strong and works well. |

After ejection, the part might need extra work like cutting off extra plastic or polishing. These steps make the product look better and work as it should.

Note: Check ejector pins and molds often for damage to keep quality steady.

Applications of Plastic Injection Molding

Industries That Use Injection Molding

Plastic injection molding is important for many industries. It is fast and flexible, making it useful for creating parts. Some industries that depend on it include:

Sector | How It Uses Plastic Injection Molding |

|---|---|

Automotive | Makes dashboards, bumpers, and car interior parts. |

Medical | Creates tools like syringes and surgical instruments. |

Packaging | Produces containers, bottle caps, and other packaging items. |

These industries enjoy making strong, precise, and affordable parts quickly.

Everyday Products Made with Injection Molding

You see items made by injection molding daily. This process helps make many products, such as:

Blades for turbines in factories.

Cases and covers for electronic devices.

Car panels and frame parts.

Boxes and containers for everyday goods.

This method works for both simple and detailed designs. From small home items to big car parts, injection molding ensures good quality every time.

Benefits for Large Production and Custom Designs

Plastic injection molding is great for making many parts or custom designs. It has advantages over other methods, such as:

Advantage | Injection Molding | Other Methods |

|---|---|---|

Fast Production | Yes | No |

Accurate and Reliable | Yes | Sometimes |

Works with Many Materials | Yes | Limited |

Saves Money | Yes | No |

For large production, it makes many parts quickly and accurately. It also allows custom molds for special designs. This makes it a top choice for industries needing speed and flexibility.

Tip: To get the best results, design molds carefully and pick the right materials for your needs.

Plastic injection molding is a useful way to shape melted plastic into strong, exact parts. It works fast and can make detailed designs, which is why it’s so important in today’s manufacturing. Industries like cars, healthcare, and packaging depend on it to make great products.

The field is changing quickly. Companies now use eco-friendly plastics that break down naturally. They also use new technology like robots and machines to work faster and waste less. These changes help the environment and make production better.

Important trends in injection molding include:

Eco-friendly materials like PLA and bio-PET.

Robots and automation for quicker, error-free work.

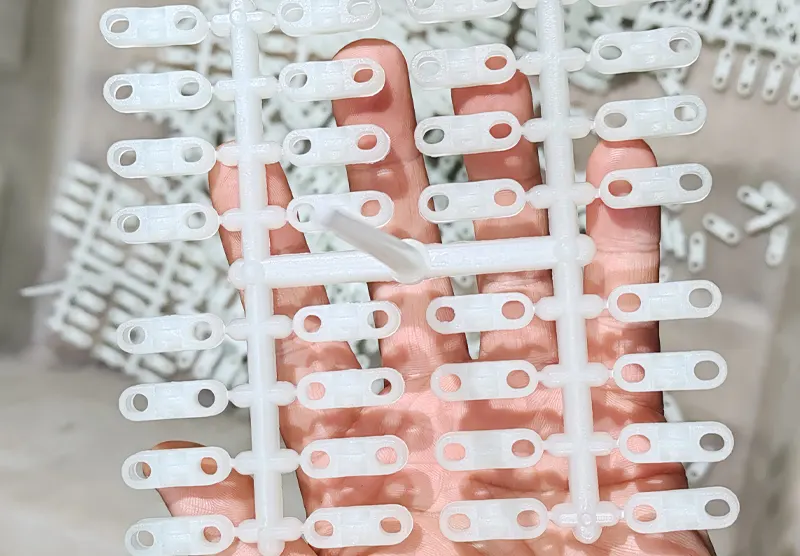

3D-printed molds to test ideas faster.

If you’re interested in designing or making products, think about using plastic injection molding. It’s flexible and creative, helping to make smart, green solutions.