Tumbling services for you

With a focus on quality, our Tumbling services provide parts that achieve high-quality surface directly, meet the demands of customers.

What is Tumbling in Surface Treatment?

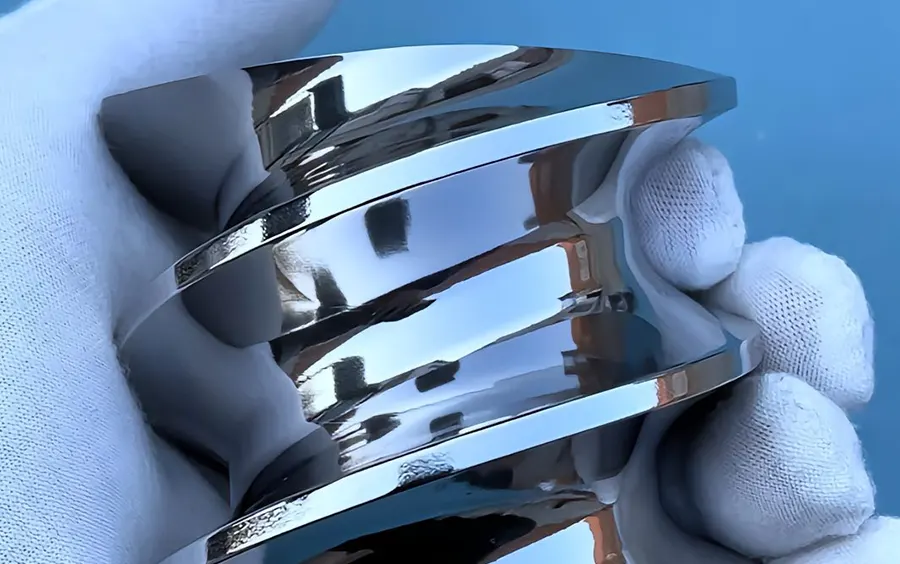

Tumbling in surface treatment is a mechanical finishing process used to improve the surface quality of parts by placing them in a rotating or vibrating barrel with abrasive media, compounds, and sometimes water. As the barrel moves, the parts rub against the media, gradually smoothing, polishing, deburring, or cleaning their surfaces.

It is widely applied in metalworking, plastics, and even ceramics for mass finishing.

Key Functions of Tumbling

- Deburring – Removes sharp edges, burrs, and small imperfections after machining, stamping, or cutting.

- Polishing – Produces smooth and shiny surfaces.

- Cleaning – Eliminates rust, scale, oil, or contaminants.

- Edge rounding – Softens edges to improve safety and functionality.

- Surface texturing – Creates uniform matte or decorative finishes.

Main Feature

Optimize your designs for manufacturability with our expert guidelines and feedback, ensuring the best results for your product.

Advantages

- Can process large batches of parts simultaneously (cost-efficient for mass production).

- Provides consistent and uniform surface quality.

- Can reach internal features and small details that are hard to finish manually.

- Reduces labor compared to hand finishing.

- Flexible: different results (from aggressive deburring to mirror polishing) can be achieved by changing media and compounds.

Disadvantages

- Less precise than manual or CNC finishing (not suitable for tight-tolerance features).

- May cause dimensional changes (especially for small or delicate parts).

- Can leave surface pitting or distortion if inappropriate media is used.

- Processing time may be relatively long depending on the desired finish

- Parts may need additional cleaning after tumbling to remove media residues.

Design Considerations for Tumbling Parts

Our CNC systems deliver tight limits that satisfy industry requirements, securing reliable accuracy and seamless component fit.

Part Size and Geometry

Surface Features

Material Selection

Tolerance and Dimensional Accuracy

Batch Processing

Desired Surface Finish

Cleaning and Post-Processing

FAQ about Tumbling

Here are some commonly asked questions and answers about our TumblingServices.

Frequently Asked Questions

All-in-One questions for Customer

What materials are suitable for tumbling?

Tumbling is suitable for metals like aluminum, steel, brass, copper, and titanium, as well as certain plastics. The choice of tumbling media and compounds is tailored to the part’s hardness, geometry, and surface finish requirements.

What are the main advantages of tumbling?

Tumbling provides uniform deburring, edge rounding, polishing, and oxide removal. It is cost-effective, capable of processing many parts at once, and enhances surface appearance while preparing parts for coatings, plating, or painting.

What are the limitations of tumbling in surface finishing?

While tumbling is effective for many applications, it may not be suitable for delicate, thin-walled, or precision parts requiring tight tolerances. Over-tumbling can round sharp edges excessively or alter dimensions.

How does tumbling compare to vibratory finishing?

Both tumbling and vibratory finishing achieve similar goals, but tumbling uses a rotating barrel, while vibratory finishing uses a vibrating bowl. Tumbling is generally more aggressive, whereas vibratory finishing offers better control for fragile parts.

Can tumbling improve corrosion resistance?

Yes. Tumbling can remove oxides, burrs, and contaminants, creating a clean surface that improves adhesion for protective coatings, plating, or passivation treatments, thereby enhancing corrosion resistance.

Is tumbling environmentally friendly?

Tumbling can be eco-friendly when using water-based compounds and recyclable media. Many modern tumbling systems include wastewater treatment and media recycling, reducing environmental impact.

What industries use tumbling in surface treatment?

Tumbling is widely used in aerospace, automotive, medical device, electronics, and general manufacturing industries. It ensures consistent surface quality, making parts safer, more reliable, and aesthetically pleasing.

How to choose the right tumbling process for my parts?

Choosing the right tumbling process depends on part geometry, material, desired finish, and production volume. Working with an experienced surface treatment provider helps select the right media, compounds, and process settings for optimal results.