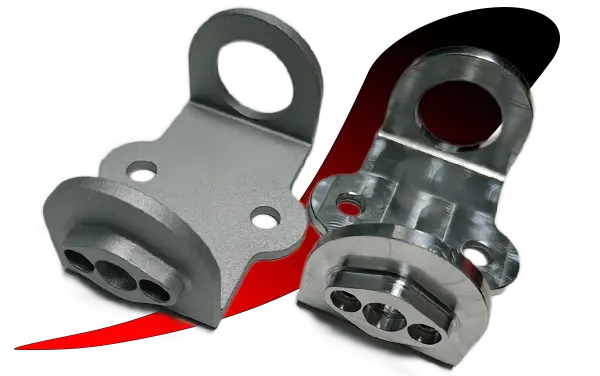

Sand Blast services for you

With a focus on quality, our Sand Blast services provide perfect parts that achieve high-quality, meet the demands of customers.

What is Sand Blast in Surface Treatment?

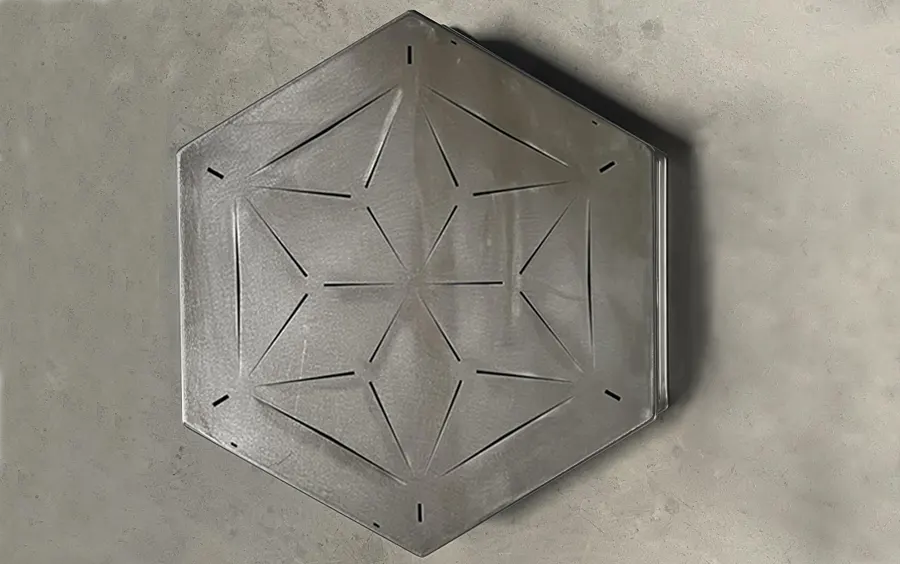

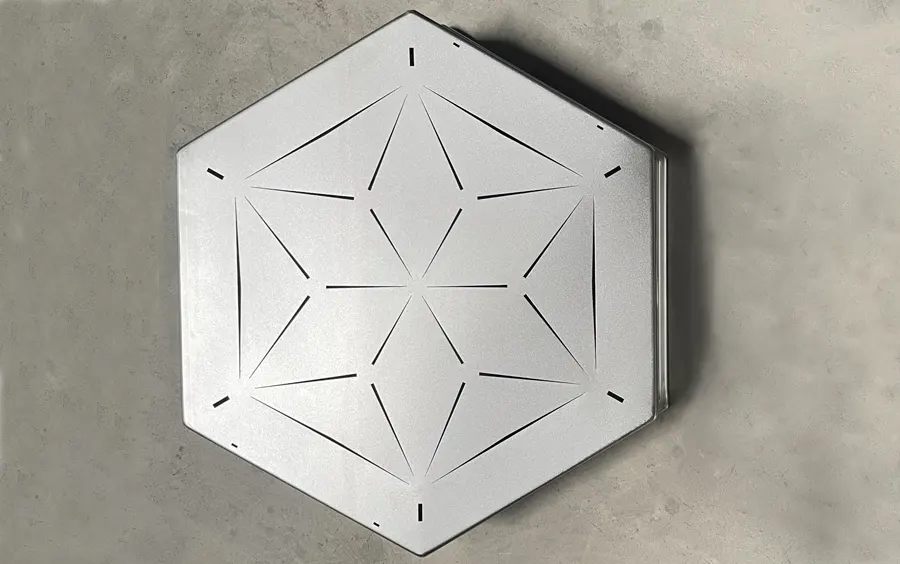

Sand blasting is a surface treatment process that involves forcibly propelling a stream of abrasive materials against a surface under high pressure to smooth out rough surfaces, remove contaminants, or shape a surface.

<>The process removes contaminants such as rust, paint, scale, grease, or old coatings and can also alter the surface texture. Depending on the abrasive and process settings, sand blasting can achieve:

- Surface cleaning – removing rust, scale, and residues.

- Surface roughening – creating an anchor profile to improve paint or coating adhesion.

- Surface finishing – achieving a matte or uniform appearance.

- Deburring – eliminating sharp edges or burrs.

It is widely applied in industries such as automotive, aerospace, shipbuilding, and metal fabrication for preparing parts before painting, anodizing, plating, or powder coating.

Main Feature

Optimize your designs for manufacturability with our expert guidelines and feedback, ensuring the best results for your product.

Advantages

- Effective Cleaning – Removes rust, paint, scale, oil, and dirt quickly and thoroughly.

- Surface Preparation – Creates a roughened texture that improves paint, coating, or adhesive bonding.

- Versatility – Works on metals, glass, wood, concrete, and plastics (with the right media).

- Time-Saving – Much faster than manual cleaning methods (grinding, wire brushing).

- Uniform Finish – Provides consistent surface roughness across large areas.

- Eco-Friendly (with correct media) – Many abrasives (e.g., garnet, glass beads) are reusable and dust can be collected with proper equipment.

- Can Reach Complex Areas – Cleans small crevices, corners, and irregular shapes where tools can’t reach.

Disadvantages

- Health Hazards – Traditional silica sand can cause silicosis (a severe lung disease) if dust is inhaled; strict PPE and dust collection systems are required.

- Surface Damage – If pressure or abrasive type is not controlled, it may warp thin metals, scratch glass, or damage delicate surfaces.

- High Noise & Dust – Generates loud noise and airborne dust, requiring protective gear and proper ventilation.

- Equipment Cost – Professional blasting machines and dust collectors are expensive.

- Environmental Concerns – If not contained, abrasive media and dust may contaminate the environment.

- Not Precise – It’s a bulk process, not ideal for highly detailed or precision-required areas.

- Material Loss – Can remove base material if overdone, especially on softer substrates.

Design Considerations for Sand Blast Parts

Our CNC systems offer precision specifications that conform to market standards, securing uniform exactness and seamless piece alignment.

Material Selection

Wall Thickness & Part Strength

Surface Roughness Requirement

Tolerance & Dimensional Accuracy

Feature Geometry

Masking Areas

Surface Coating Preparation

Part Size & Accessibility

Residual Stress & Fatigue

FAQ about Sand Blast

Get to know our Sand Blast Services better through these frequently asked questions and answers.

Frequently Asked Questions

All-in-One questions for Customer

What are the disadvantages of sandblasting?

The main drawbacks include potential health risks from dust exposure, possible damage to delicate surfaces, high noise levels, and additional costs for equipment and dust control. Proper safety measures and media selection are essential.

What materials can be treated with sandblasting?

Sandblasting is suitable for steel, aluminum, stainless steel, titanium, concrete, wood, and even glass (using softer abrasives). Material hardness and thickness should always be considered to avoid damage.

What abrasive media are commonly used in sandblasting?

Common abrasives include silica sand, aluminum oxide, garnet, glass beads, walnut shells, and steel grit. The choice depends on the desired surface finish, material hardness, and environmental considerations.

How does sandblasting affect surface roughness?

Sandblasting increases surface roughness (Ra), which enhances coating adhesion. However, the finish can range from matte to highly textured depending on abrasive type, size, and blasting pressure.

Is sandblasting environmentally friendly?

Modern sandblasting can be eco-friendly if reusable abrasives (like glass beads or garnet) and dust collection systems are used. Traditional silica sand is less safe and should be avoided due to silicosis risks.

What safety precautions are required for sandblasting?

Operators must wear protective clothing, respirators, gloves, and ear protection. Enclosures, dust collectors, and ventilation systems should be in place to control airborne particles and ensure workplace safety.

What design considerations should be made for sandblasted parts?

Parts should be designed with adequate wall thickness, accessible surfaces, and non-critical tolerances in blasted areas. Masking may be required for precision surfaces, sealing areas, or threaded holes.

What industries commonly use sandblasting for surface treatment?

Sandblasting is widely used in automotive, aerospace, shipbuilding, construction, oil & gas, and manufacturing. It plays a critical role in rust removal, surface preparation, and extending the life of protective coatings.