Powder Coating services for you

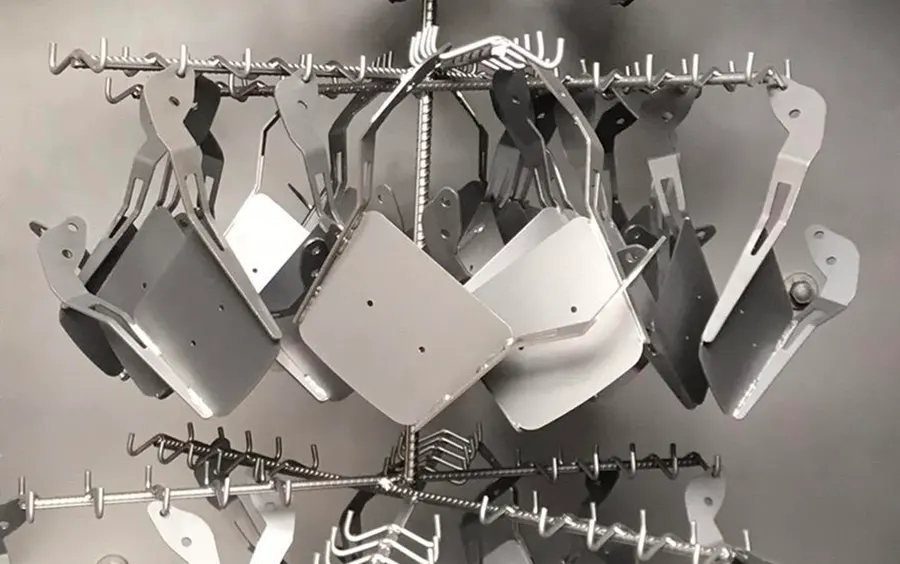

With a focus on quality, our Powder Coating services provide parts that achieve high-quality surface directly, meet the demands of customers.

What is Powder Coating in Surface Treatment?

Powder coating is a surface treatment process that applies a dry, free-flowing powder onto a metal substrate to create a durable, protective, and decorative finish.

Unlike liquid paint, it does not require solvents; instead, the powder is electrostatically charged and sprayed onto the part’s surface, then cured under heat to form a smooth, uniform coating.

This method provides excellent resistance to corrosion, chemicals, and wear, while also offering a wide range of colors and textures.

Powder coating is widely used in industries such as automotive, aerospace, appliances, and architectural products due to its durability, cost-effectiveness, and environmentally friendly characteristics.

We provide professional powder coating services to enhance both the durability and appearance of your metal parts.

Main Feature

Unlike liquid coatings, powder coating uses dry powder applied electrostatically and cured under heat, creating a hard, uniform layer that adheres strongly to the substrate.

Advantages

- Durability – Creates a tough, impact-resistant surface that resists chipping, scratching, and fading.

- Corrosion and Chemical Resistance – Provides strong protection against rust, moisture, and chemicals.

- Aesthetic Versatility – Available in a wide range of colors, textures, and finishes (matte, glossy, metallic, textured).

- Environmental Benefits – Contains no solvents, emits almost no VOCs, and allows overspray to be recycled, minimizing waste.

- Uniform Coating – The electrostatic application ensures even coverage, even on complex geometries.

- Cost-Effective Long-Term – Low maintenance needs and long service life reduce lifecycle costs.

Disadvantages

- Initial Equipment Cost – Requires specialized application and curing equipment, which can be expensive for small operations.

- Limited Material Compatibility – Can only be applied to substrates that can withstand curing temperatures (typically 160–210°C), excluding many plastics and composites.

- Difficult to Repair – Touch-ups are more challenging compared to liquid paint; damaged areas often need to be recoated entirely.

- Thickness Control Limits – Achieving very thin, precise coatings can be difficult compared to wet painting.

- Color Change Challenges – Switching colors during production can be time-consuming and may lead to powder waste.

Design Considerations for Powder Coating Parts

Our CNC equipment offer tight limits that meet sector standards, ensuring uniform precision and seamless component alignment.

Material Compatibility

Geometry and Accessibility

Sharp Edges & Burrs

Edge and Corner Treatment

Surface Preparation

Threaded Holes and Mating Surfaces

Coating Thickness

Large Parts and Weight

Color and Finish Requirements

FAQ about Powder Coating

Here are some commonly asked questions and answers about our Powder CoatingServices.

Frequently Asked Questions

All-in-One questions for Customer

What materials can be powder coated?

Powder coating is most commonly applied to metals such as steel, aluminum, and stainless steel, but newer formulations allow coating on heat-resistant plastics, glass, and composites. The substrate must withstand curing temperatures of 160–210 °C without degrading.

What are the main advantages of powder coating compared to liquid paint?

Powder coating provides superior durability, chemical resistance, impact resistance, and color retention. It also produces a more uniform finish, is environmentally friendly (low VOC emissions), and generates minimal waste since overspray can often be recycled.

Are there any disadvantages of powder coating?

Yes. Powder coating requires specialized equipment and curing ovens, limiting the size of parts that can be coated. Thin film finishes (<30 μm) are difficult to achieve, and masking is required for surfaces that should not be coated. Additionally, repairs or touch-ups are more challenging compared to liquid paint.

What industries use powder coating the most?

Powder coating is widely used in automotive, aerospace, architecture, consumer appliances, electronics, agricultural equipment, and general manufacturing. It is favored in applications that demand high durability, corrosion resistance, and aesthetic appeal.

What is the typical thickness of a powder coating layer?

Standard powder coating thickness ranges between 50–150 microns (μm) depending on application requirements. Thicker coatings are used for heavy-duty protection, while thinner coatings are used when precise tolerances must be maintained.

How long does powder coating last

When properly applied and cured, powder coating can last 15–20 years or more, depending on environmental exposure and substrate preparation. UV-resistant powders extend outdoor performance, while high-durability coatings provide long-lasting protection in industrial environments.

What surface preparation is required before powder coating?

Surface preparation is critical. Substrates must be cleaned of oil, rust, and scale using methods such as degreasing, sandblasting, or chemical pretreatment. Proper preparation ensures adhesion, corrosion resistance, and coating longevity.

Can powder coating be applied in custom colors and finishes?

Yes. Powder coatings are available in thousands of colors, gloss levels, and textures, including metallic, matte, satin, and high-gloss finishes. Special-effect powders such as hammertone, wrinkle, or pearlescent coatings are also available for aesthetic or functional purposes.

What are the environmental benefits of powder coating?

Powder coating is considered eco-friendly because it emits near-zero volatile organic compounds (VOCs), produces minimal hazardous waste, and allows unused powder to be recycled. This makes it a sustainable alternative to traditional wet painting.