Electroless Plating services for you

With a focus on quality, our Electroless Plating services provide parts that achieve high-quality surface directly, meet the demands of customers.

Electroless Plating for Your Perfect Product

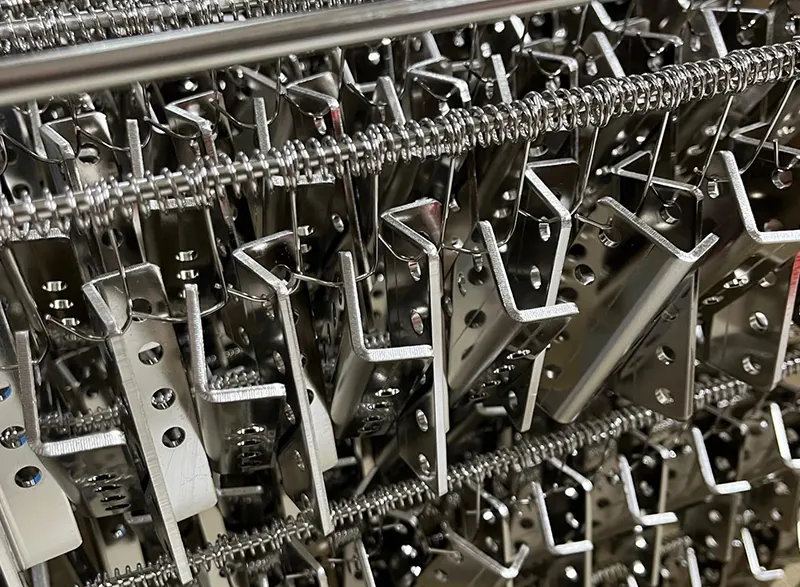

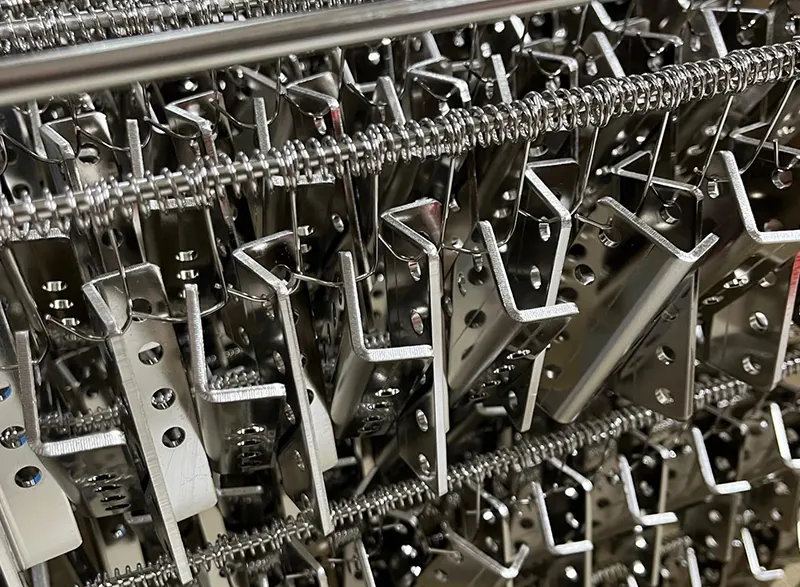

Electroless plating is a chemical deposition process that creates a uniform, high-performance metal coating on various substrates without the need for external electricity.

This technique ensures excellent coverage on complex geometries, blind holes, and internal surfaces, offering superior corrosion resistance, wear resistance, and enhanced conductivity.

At Tonzamaking, we provide professional electroless plating services tailored to meet the diverse needs of our customers.

With our advanced technology and skilled team, we deliver precise, durable coatings that enhance product performance and reliability across industries such as electronics, aerospace, automotive, and industrial manufacturing.

Main Feature

Electroless plating creates a uniform, adherent metal coating without electricity, using chemical reduction. This process ensures even coverage on complex shapes, enhancing corrosion resistance, wear resistance, and conductivity.

Advantages

- Provides uniform coating thickness, even on complex geometries and blind holes.

- Enhances corrosion resistance, wear resistance, and hardness.

- Improves conductivity for electronic components.

- Does not require electricity or external power sources.

- Offers strong adhesion to a wide range of substrates.

Disadvantages

- Higher cost compared to traditional electroplating.

- Slower deposition rate, which can extend processing time

- Bath solutions require precise control and regular maintenance.

- Limited choice of coating materials compared to electroplating.

- Shorter bath life and potential for waste disposal issues.

Design Considerations for Electroless Plating Parts

Our CNC systems deliver tight specifications that conform to industry norms, guaranteeing uniform precision and seamless part integration.

Material compatibility

Geometry and accessibility

Tolerance control

Surface finish

Masking requirements

Coating selection

Heat treatment needs

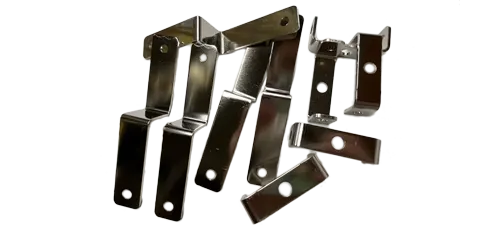

Show Case

FAQ about Electroless Plating

We’ve gathered the most relevant questions and answers to guide you through our Electroless Plating Services.

Frequently Asked Questions

All-in-One questions for Customer

What is electroless plating and how does it differ from electroplating?

Electroless plating is a chemical deposition process that coats surfaces without using an external electric current, unlike electroplating. It relies on an autocatalytic reaction, producing highly uniform coatings even on complex geometries.

What materials can be coated with electroless plating?

Electroless plating can be applied to a wide range of substrates, including metals like steel, copper, and aluminum, as well as non-metals such as plastics and ceramics after suitable pretreatment.

How thick is a typical electroless plating layer?

Electroless plating thickness usually ranges from 2 to 50 microns, depending on the application. Thicker coatings can be applied when greater wear resistance or corrosion protection is required.

What are the common types of electroless plating?

The most common types are electroless nickel-phosphorus, electroless nickel-boron, and electroless copper, each selected based on performance needs such as hardness, conductivity, or chemical resistance.

Is electroless plating suitable for complex part geometries?

Yes, electroless plating provides uniform coatings on intricate shapes, blind holes, threads, and internal surfaces where electroplating often struggles to reach.

What industries commonly use electroless plating?

Electroless plating is widely used in automotive, aerospace, defense, electronics, medical devices, and oil & gas industries due to its durability and precision.

How does electroless plating improve corrosion resistance?

The chemical deposition forms a dense, pore-free layer that protects the substrate from oxidation, chemicals, and harsh environmental conditions, extending the service life of parts.

What are the limitations of electroless plating?

While highly effective, electroless plating can be more expensive than electroplating, requires strict bath maintenance, and has limited material options compared to traditional methods.

How should engineers design parts for electroless plating?

Engineers must consider plating thickness in tolerances, ensure smooth base finishes, avoid chemical entrapment in blind cavities, and specify masking for areas that should remain uncoated.