flexible, cost-effective path from prototype to market-ready products.

Low Volume Manufacturing Service

Enables cost-effective, flexible, and scalable manufacturing, bridging the gap between prototyping and mass production.

- Rapid 3D printing, CNC machining, sheet metal, and injection molding.

- Lead time as fast as 1 day.

Start Your Project

STEP | STP | PRT | SLD | SAT | X_T | DWG | JPG | PNG | PDF

Max. file size: ≤10MB

Why do We need Low Volume Manufacturing?

Rapid prototyping in manufacturing is a process used to quickly create physical models or parts using advanced fabrication technologies. It allows manufacturers to produce prototypes for testing, design validation, and low-volume production before committing to full-scale manufacturing.

Market Testing

Faster Time to Market

Cost-Effective for Small Runs

Design Flexibility & Iteration

Supply Chain Flexibility

Ideal for Startups & Small Businesses

Why Choose ours Low Volume Production Service?

delivering exceptional results through experience, dedication, and strategic thinking.

working closely with clients to understand their unique needs and goals

featuring the latest technology and advanced machinery to ensure precision, efficiency.

leveraging cutting-edge technology to manufacture intricate components

delivering exceptional value without compromising on quality or precision.

ensuring fast, efficient, and reliable production without compromising quality.

Main Types of Manufacturing Services

Low-volume manufacturing plays a crucial role in product development and business strategy, offering flexibility, cost savings, and faster market entry.

CNC Machining for for Low Volume Production

We specialize in providing precision CNC machining services for low-volume production, offering fast, reliable, and cost-effective solutions for a wide range of industries.

Whether you need functional prototypes, custom parts, or complex components, our CNC milling and CNC turning services are designed to meet your specific requirements with exceptional accuracy and durability.

With the ability to work with a variety of metals and plastics, we ensure that each part is produced to the highest standards of precision. Our low-volume CNC machining allows for rapid prototyping, fast lead times, and the flexibility to modify designs as needed, making it an ideal solution for testing, market validation, or specialized production runs.

Choose TONZA for your CNC machining needs, and experience high-quality results, delivered quickly and efficiently, to accelerate your product development process.

Injection Molding for for Low Volume Production

At TONZA, we offer high-quality injection molding services for low-volume production, delivering precision-engineered plastic parts for a wide range of industries. Whether you need prototypes, functional components, or customized plastic products, our injection molding solutions ensure fast turnaround, affordable pricing, and exceptional consistency.

We use advanced injection molding techniques and work with a variety of thermoplastic materials to meet your specific product needs. From creating temporary bridge tooling for product launches to producing high-quality parts in small batches, we provide flexible and efficient manufacturing to accelerate your development process.

Choose TONZA for your low-volume injection molding needs, where you’ll receive durable, reliable parts quickly and efficiently, helping you bring your ideas to life.

Our expertise guarantees precise, reliable prototypes, supporting seamless product development and testing.

Sheet Metal for for Low Volume Production

At TONZA, we specialize in sheet metal fabrication for low-volume production, offering precise, cost-effective solutions for a wide range of industries. Whether you need custom enclosures, brackets, chassis, or other sheet metal components, our services provide fast turnaround and high-quality results tailored to your specific needs.

Using advanced techniques such as laser cutting, punching, bending, and welding, we can produce intricate and durable sheet metal parts in small batches, allowing you to test designs, make adjustments, or fulfill small-scale production runs. Our team ensures that every piece meets the highest standards of precision, strength, and durability.

TONZA is your go-to partner for flexible, low-volume sheet metal manufacturing, providing the ideal balance of speed, quality, and cost-efficiency for your production needs.

3D Printing for for Low Volume Production

At TONZA, we specialize in providing high-quality 3D printing solutions for low-volume production runs. Whether you’re looking to test prototypes, create custom parts, or validate designs, our 3D printing services offer fast turnaround times, cost-effective pricing, and exceptional precision.

We leverage advanced 3D printing technologies like Selective Laser Sintering (SLS), Stereolithography (SLA), and Fused Deposition Modeling (FDM) to produce detailed, durable parts that meet your exact specifications. This makes us the ideal choice for industries like automotive, aerospace, medical devices, and consumer products where quick prototyping and high-quality results are essential.

With TONZA, you gain access to a flexible, scalable solution that supports your low-volume production needs, ensuring fast and reliable results at any stage of your product development process.

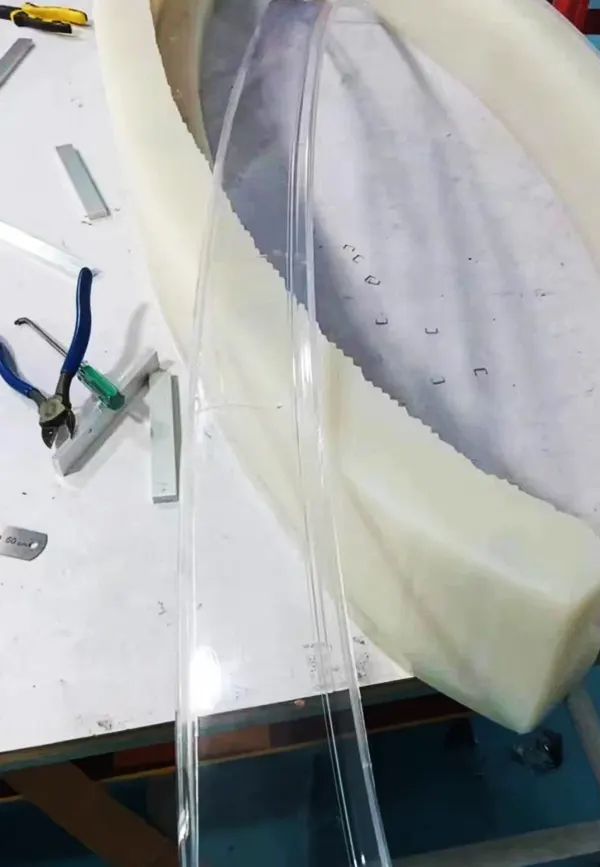

Vacuum Casting for for Low Volume Production

We provide vacuum casting services designed for low-volume production, delivering high-quality, precise parts for a variety of industries. This technique is ideal for creating functional prototypes, custom parts, and short-run production of plastic components, providing a cost-effective and efficient solution without the need for expensive tooling.

Our vacuum casting process allows us to create parts with excellent detail, surface finish, and mechanical properties, using a variety of rubber-like and rigid materials. This is perfect for industries like automotive, consumer products, medical devices, and more, enabling you to test and refine your designs before moving to full-scale manufacturing.

Choose TONZA for your vacuum casting needs, and enjoy fast turnarounds and reliable, high-quality results for your low-volume production projects.

Difference

Each stage plays a critical role in product development, ensuring smooth transitions from concept to full-scale market release.

| Item | Rapid Prototyping | Low Volume Production | Massive Production |

|---|---|---|---|

| Purpose | Design validation & testing | Short-term production before mass manufacturing | meet market demand |

| Key Benefit | Fast iterations, low initial cost | Fills the gap before full-scale production | High efficiency, low cost per unit for large production runs |

| Demand for equipment | Smaller Tool Stock, More complex machines | Bigger Tool Stock, Complex machines | Bigger Tool Stock, Simple machines |

| Demand for jigs | Predominantly standard fixtures. | A few custom-made fixtures. | Custom Made Fixture |

| Reachable Tolerance | Highly precise with significant variance. | Highly precise with significant variance. | Accurate with slight variance. |

| Price | Very expensive per Unit | expensive per Unit | Low per unit |

| Lead Time | 1-4 business days | 5-12 business days | 2-4 weeks |

| Capability | 1-50 pcs | 51-10,000 pcs | Above 10,001 pcs |

Application Industries

Optimize your designs for manufacturability with our expert guidelines and feedback, ensuring the best results in CNC machining.

FAQ

To provide clarity on our services, here are answers to frequently asked questions about prototyping and manufacturing.

Low-volume production offers faster time to market, cost savings, and design flexibility. It’s perfect for market testing, customization, and minimizing risks before committing to high-volume manufacturing.

We offer rapid turnaround times, with many parts being ready within days. Depending on the complexity of your design, some prototypes can be delivered in as little as one day.

Low-volume production is ideal for prototypes, specialized products, and limited-edition runs across industries like automotive, aerospace, medical devices, and consumer electronics.

TonZa uses a variety of methods, including CNC machining (milling and turning), 3D printing, injection molding, and sheet metal fabrication to meet the needs of your project.

Yes, we specialize in machining a wide range of metals and plastics, allowing us to customize materials to fit your project’s specifications, ensuring high precision and durability.

Cost varies depending on the material, production method, and complexity of the design. TonZa offers competitive, market-driven pricing, ensuring affordability without compromising quality.

You can contact us directly to discuss your project’s requirements. After reviewing your design, we will provide a quote, timeline, and guide you through the production process.

TonZa offers high-quality, precision-driven services with quick turnaround times, cost-effective solutions, and a commitment to customer satisfaction, helping you develop reliable products from concept to final production.

Blog

Welcome to our blog, where we share insights into various manufacturing processes.