Get your custom metal and plastic parts ordered today.

Online CNC Turning service

Receive an instant online quote for your CNC-turned metal or plastic parts, whether for rapid prototyping or full-scale production.

- Our in-house machine shop operates 24/7, ensuring quick turnaround times.

- Tolerances up to ±0.0004″ (0.01mm)

- Lead times as short as 1 day.

On Demand CNC Turning Services

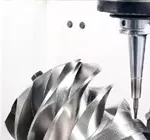

CNC Turning and CNC Turn-Mill machining offer enhanced precision and speed for parts with mainly cylindrical features. Using CNC lathes with multiple turning tools, we ensure fast, accurate manufacturing—perfect for parts that are primarily cylindrical but include complex features like flats, slots, and holes.

Grooving

Threading

Parting

Boring

Knurling

Taper Turning

Spherical Generation

Cylindrical Turning

Why Choose ours CNC Turning Services?

delivering exceptional results through experience, dedication, and strategic thinking.

working closely with clients to understand their unique needs and goals

featuring the latest technology and advanced machinery to ensure precision, efficiency.

leveraging cutting-edge technology to manufacture intricate components

delivering exceptional value without compromising on quality or precision.

ensuring fast, efficient, and reliable production without compromising quality.

Capabilities of CNC Turning Services

Our CNC machines achieve industry-standard precision tolerances, guaranteeing consistent accuracy and a perfect component fit.

Maximum Diameter: 500mm or 19.7-inch

Max Length: 1800mm or 70.9-inch

Metal: 0.5mm or 0.02 in

Plastic: 1.0mm or 0.04 in

Metal: +/- 0.005mm (+/-0.0002 in)

Plastic: +/-0.025mm(+/-0.001 in)

4 bussiness days for most projects.

simple parts can be as fast as 1 day.

Design Guidelines

Optimize your designs for manufacturability with our expert guidelines and feedback, ensuring the best results in CNC Turning.

Minimum and Maximum Part Dimensions

2. Max outer diameter (OD): ~500 mm (varies by lathe size).

3. Max length: Typically up to 1000 mm, depending on machine size.

Wall Thickness

2. Plastic parts: ≥ 1.0 mm to avoid deformation.

3. Avoid excessive thin walls to prevent part vibration and bending.

Tolerances

2. Tight tolerances: ±0.01 mm (increases machining cost).

3. Specify critical tolerances only to optimize production efficiency.

Internal and External Diameters

2. Recommended max depth for internal bores: 4× diameter (beyond this, special tooling is needed).

3. Avoid sharp corners in internal features—use a minimum fillet radius of 0.5 mm.

Threading Guidelines

2. External threads: Specify standard thread types to reduce custom tool costs.

3. Recommended thread depth: 1.5× diameter to maintain strength.

Length-to-Diameter Ratio

2. Higher ratios (>6:1) require steady rests or tailstock support to prevent deflection and vibration.

Avoid Deep Drilling

2. Deeper holes require special drills and peck drilling, increasing machining time.

3. Minimum hole diameter: 1 mm (varies by machine and tooling).

Avoid Deep Drilling

2. Deeper holes require special drills and peck drilling, increasing machining time.

3. Minimum hole diameter: 1 mm (varies by machine and tooling).

Materials for CNC Turning

CNC technology enables the machining of a wide range of materials with precision and efficiency. At TonZa, we offer CNC machining quotes for over 30 engineering-grade plastics and metals, ensuring versatility for various applications. Additionally, a variety of surface finishes can be applied to enhance the appearance and functionality of CNC-machined parts.

Metal

Tipical: Aluminum, Steel, Stainless Steel, Brass, Bronze, Copper, Magnesium Alloy, Titanium Alloy, Zinc Alloy and etc.

Plastic

Tipical: ABS, PC, ABS+PC, PMMA (Acrylic), PA (Nylon), PA+GF30, POM (Acetal/Delrin), PP, PVC, HDPE, PPS, PEEK and etc.

Surface Finishes

We are offering over 20 options of surface finishes to fulfill both your functional and aesthetic requirements.