Order custom metal and plastic parts tailored to your needs.

Online CNC Milling Services

CNC milling services on demand for rapid prototypes and production parts. If you have any demand, please contact us.

- Our in-house machine shop runs 24/7, guaranteeing fast turnaround times.

- Tolerances up to ±0.0004″ (0.01mm)

- Lead times as short as 1 day.

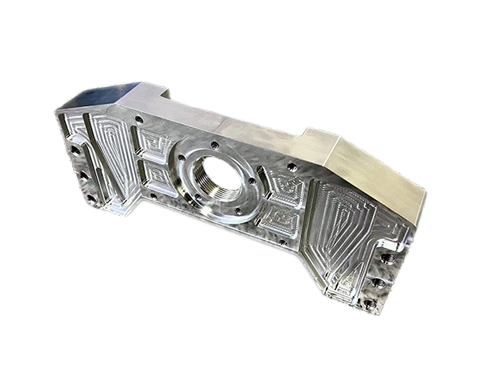

Custom CNC Milling Services

We provide comprehensive CNC machining services, including milling, turning, drilling, tapping, EDM (Electrical Discharge Machining), and wire EDM, for a variety of materials.

3-Axis CNC Milling

4-Axis CNC Milling

5-Axis CNC Machining

Why Choose ours CNC Milling Services?

delivering exceptional results through experience, dedication, and strategic thinking.

working closely with clients to understand their unique needs and goals

featuring the latest technology and advanced machinery to ensure precision, efficiency.

leveraging cutting-edge technology to manufacture intricate components

delivering exceptional value without compromising on quality or precision.

ensuring fast, efficient, and reliable production without compromising quality.

Capabilities of CNC Milling Services

Our CNC machines deliver precision tolerances that meet industry standards, ensuring consistent accuracy and seamless component fit.

| 3-Axis | 4-Axis | 5-Axis | |

|---|---|---|---|

| Maximum Size | 1000 x 500 x 500 mm | 1000 x 500 x 500 mm | 1000 x 500 x 500 mm |

| Minimum Size | 5 x 5 x 5 mm | 5 x 5 x 5 mm | 5 x 5 x 5 mm |

| General Tolerances | ±0.05 mm | ±0.05 mm | ±0.05 mm |

| Lead Time | as fast as 1 day. | 4 bussiness days | more than 5 bussiness days |

Design Guidelines

Optimize your designs for manufacturability with our expert guidelines and feedback, ensuring the best results in CNC machining.

Internal and External Radii

2. Larger radii (e.g., R2 mm or larger) improve tool accessibility and longevity.

3. Avoid sharp internal corners; CNC tools have rounded edges.

Minimum Wall Thickness

2. Plastic parts: ≥ 1.5 mm (to prevent deformation and warping).

3. Thinner walls increase machining difficulty and risk of breakage.

Pocket and Cavity Depths

2. Deep cavities (above 50 mm) may require specialized tooling or multi-step machining.

Text and Engraving

2. Use simple sans-serif fonts (e.g., Arial) for better legibility

3. Raised text is more costly than engraved text..

Tolerances

2. Tighter tolerances (e.g., ±0.01 mm) increase machining time and cost.

3. Specify critical dimensions only to balance precision and efficiency.

Undercuts and Special Features

2. If undercuts are required, specify standard undercut sizes for easier machining.

Chamfers and Fillets

2. Chamfers: Suitable for edges and deburring.

3. Fillets: Reduce sharp transitions in internal pockets.

Surface Finishes

2. Tighter surface finish requirements (e.g., Ra 0.8 µm) increase machining cost.

Materials for CNC Milling

CNC technology enables the machining of a wide range of materials with precision and efficiency. At TonZa, we offer CNC machining quotes for over 30 engineering-grade plastics and metals, ensuring versatility for various applications. Additionally, a variety of surface finishes can be applied to enhance the appearance and functionality of CNC-machined parts.

Metal

Tipical: Aluminum, Steel, Stainless Steel, Brass, Bronze, Copper, Magnesium Alloy, Titanium Alloy, Zinc Alloy and etc.

Plastic

Tipical: ABS, PC, ABS+PC, PMMA (Acrylic), PA (Nylon), PA+GF30, POM (Acetal/Delrin), PP, PVC, HDPE, PPS, PEEK and etc.

Surface Finishes

We are offering over 20 options of surface finishes to fulfill both your functional and aesthetic requirements.