CNC Machining Services forRenton, Washington

Accurate, Reliable, CNC Machining.

Introducing TonzaMaking, a leading provider of CNC machining services for Washington. With state-of-the-art technology and a team of skilled professionals, we are dedicated to delivering high-quality machining solutions to meet the needs of our clients. Our precision machining services are designed to offer precise and efficient results for a wide range of industries in Washington.

We specialize in CNC machining services that cater to various applications, including prototyping, production runs, and custom projects. Whether you require turning, milling, drilling, or other machining processes, our team has the expertise and resources to deliver exceptional results. At TonzaMaking, we prioritize customer satisfaction and strive to exceed expectations with our reliable and cost-effective machining solutions.

Choose TonzaMaking for all your CNC machining needs in Washington and experience the difference our expertise can make. Contact us today to learn more about our services and how we can assist with your machining requirements. Trust TonzaMaking for top-notch CNC machining services that are tailored to your specific needs and preferences.

Most important Joining

"We are a professional machining service provider based in China, looking to build a global network founded on mutual benefit. If you're involved in the manufacturing industry—whether you run your own workshop or bring engineering expertise—we’d be glad to explore potential collaboration with you. Feel free to reach out to discuss how we can work together."

TonZamaking

Type of CNC Machining Services for Renton

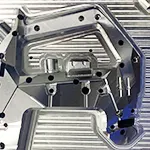

With a strong focus on

5-axis machining, CNC milling, and turning, Tonza deliver consistent, exceptional accuracy parts with rapid and reliability across diverse industries.

CNC Milling services

CNC Turnning services

5-Axis CNC Machining

Precision Machining Services

Capabilities of CNC Machining Services for Renton

Our CNC machines deliver exacting dimensional accuracy that are manufactured following regulatory guidelines, providing repeatable accuracy in production.

Tolerances

±0.05mm

Impeccably executed engineering detail to deliver elite product functionality.

Max part size

200 x 80 x 100 cm

Armed with next-gen machinery, customized to meet client needs.

Wall Thickness

0.75 mm

Driven by state-of-the-art production capabilities., focused on surpassing customer goals.

Lead Time

< 10 days

Robust and agile administrative framework, and efficient workflow balancing quality and speed.

Why Choose Ours CNC Machining Services?

Delivering superior results through a combination of experience, dedication, and tactical thinking.

Working hand-in-hand with clients to identify their distinct needs and ambitions.

Utilizing top-tier machinery and modern technology to guarantee precise and efficient results.

Offering excellent value while upholding top-tier quality and precision.

CNC Machining Solutions for Renton, Washington

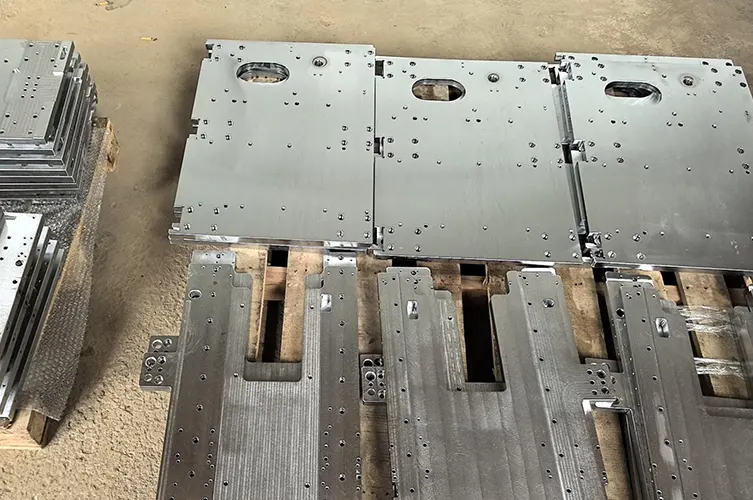

Backed by years of refined practice, we offer CNC milling, turning, and 5-axis machining services, ensuring right, fast, and reliable components for diverse applications.

Rapid prototyping | Bridge Production | Massive Production |

|---|---|---|

Smaller Tool Stock, More Axis | Big Tool Stock, More Axis | Bigger Tool Stock, Less Axis |

Predominantly standard fixtures. | A few custom-made fixtures. | Custom Made Fixture |

Highly precise with significant variance. | Highly precise with significant variance. | Accurate with slight variance. |

Very expensive per Unit | expensive per Unit | Low per unit |

LT: 1-4 business days | LT: 5-12 business days | Lead Time: 2-4 weeks |

Capability: 1-50 pcs | Capability: 51-10,000 pcs | Capability: Above 10,001 pcs |

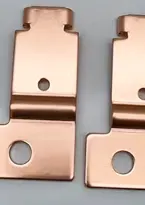

Surface Finishes for Washington Customer

Tonza’s selection includes 20+ surface finishes designed to fulfill both functional and cosmetic requirements.

Brushing

Sand Blast

Polishing

Tumbling

Anodizing

Painting

Black Oxide

Powder Coating

Electroplating

Alodine

Passivation

Electroless Plating

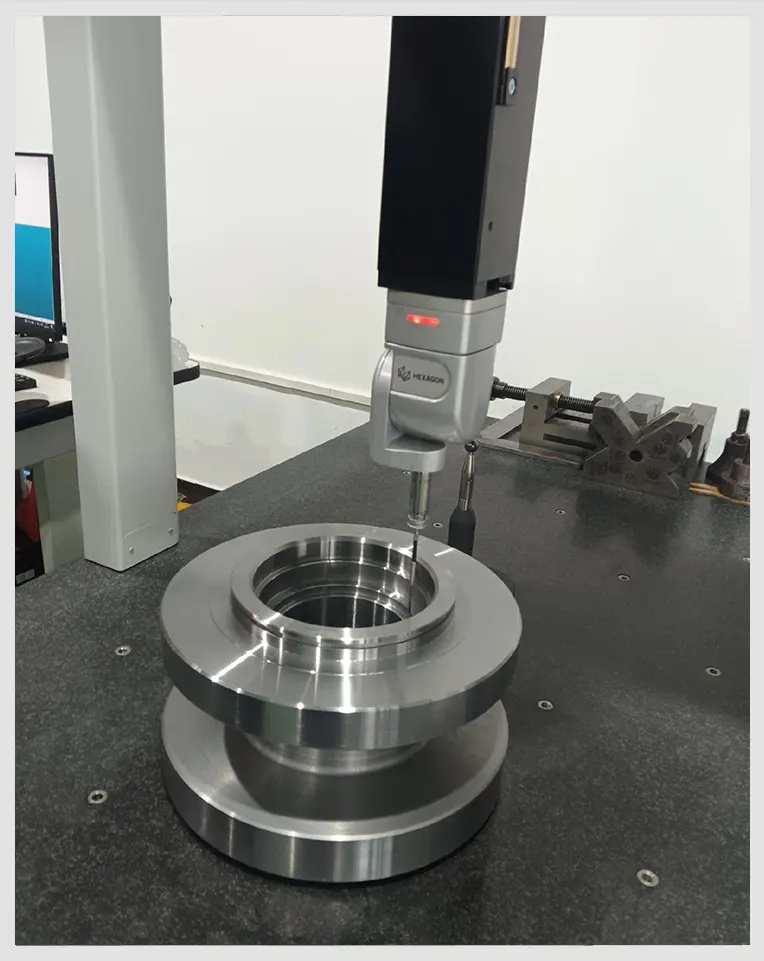

Certifications & Quality Standards

Tonza produce CNC components with consistent accuracy, meeting tight tolerances and enabling precise integration of parts.

Tolerances are maintained in accordance with ISO 2768 standards.

TonZa is proud to announce that it has achieved ISO9001 certification for its quality management system. This certification signifies the company’s dedication to maintaining high standards of quality control in all aspects of its production process. By adhering to strict quality control procedures, TonZa ensures that every product that leaves its facilities meets the highest level of quality for Renton’s customers.

With a focus on quality control, TonZa is able to consistently produce goods that not only meet but exceed the expectations of its customers. The commitment to quality control is evident in the attention to detail and precision that goes into every step of the production process. From raw materials sourcing to final product inspection, TonZa’s quality management system is designed to ensure that only the best products are delivered to Renton’s customers.

Customers can trust that when they purchase products from TonZa, they are receiving high-quality goods that have been manufactured with care and precision. By prioritizing quality control, TonZa sets itself apart as a reliable and trustworthy supplier that places the satisfaction of Renton’s customers above all else.

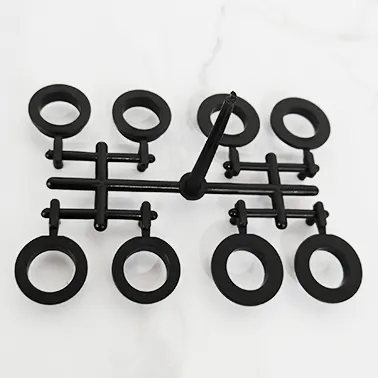

Other Machining Capabilities

In Washington, USA, we deliver CNC machining, sheet metal fabrication, die casting, and additional manufacturing capabilities.

Injection Molding

Sheet Metal Fabrication

High Pressure Die Casting

Vaccum Casting

3D Printing

CNC Machining Services Locations Near Renton, Washington

{Our deep experience in 5-axis machining, CNC milling, and turning allows us to delivering precision, precision, and durable precision components.}

FAQ

Here, we’ve listed some of the most common questions about CNC machining services for Renton, Washington. “If you can’t find a satisfactory answer, please contact us.“