CNC Machining Services forCalifornia, USA

Engineering Excellence, Machined to Perfection.

Welcome to TonzaMaking, your premier provider of CNC machining services for California. With years of experience in the industry, we are dedicated to delivering precise and top-quality machining solutions to our clients in California.

Our team at TonzaMaking prides itself on our state-of-the-art equipment and expert machinists who are committed to meeting all of your CNC machining needs. Whether you require prototyping, production runs, or custom machining, we have the capabilities to fulfill your requirements with accuracy and efficiency.

At TonzaMaking, we understand the importance of staying at the forefront of technological advancements in the machining industry. That’s why we continually invest in the latest CNC machining technologies to deliver unmatched service and craftsmanship to our clients in California. Trust TonzaMaking for all your CNC machining needs and experience the precision and quality that sets us apart from the competition.

Most important Joining

"We are a professional machining service provider based in China, seeking participants to establish a global network based on win-win. If you are involved in the manufacturing industry—whether you operate your workshop or have engineering expertise—we welcome the opportunity to collaborate. Please get in touch with us to explore potential cooperation."

TonZamaking

Type of CNC Machining Services for California

Specializing

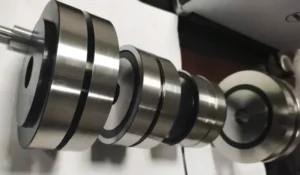

turning, CNC milling, and 5-axis machining, we produce reliable, high-quality components with rapid and reliability across diverse industries.

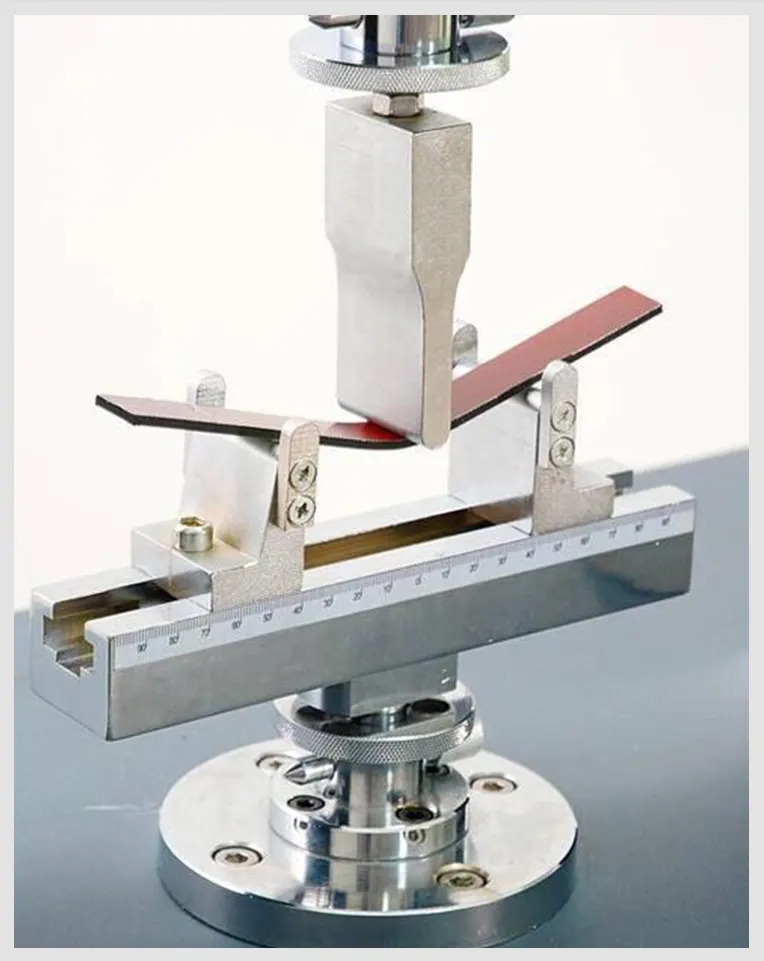

CNC Milling services

CNC Turnning services

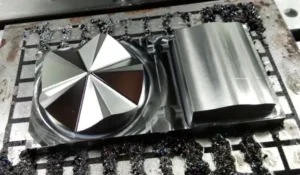

5-Axis CNC Machining

Precision Machining Services

Capabilities of CNC Machining Services for California

Our CNC machines consistently uphold strict measurement standards that are engineered to meet demanding industry requirements, optimizing tolerance for perfect fit and function.

Tolerances

±0.05mm

Impeccably executed engineering detail to deliver consistent quality you can rely on.

Max part size

200 x 80 x 100 cm

Enhanced with cutting-edge fabrication equipment, focused on delivering tailored client outcomes.

Wall Thickness

0.75 mm

Enhanced through top-tier platforms, aligned with exact client requirements.

Lead Time

< 10 days

Robust and agile administrative framework, and quick and consistent output.

Why Choose Ours CNC Machining Services?

Achieving outstanding outcomes through expertise, commitment, and thoughtful strategy.

Engaging with clients to comprehend their unique needs and aspirations.

Equipped with state-of-the-art technology and cutting-edge machinery for optimal precision and efficiency.

Offering excellent value while upholding top-tier quality and precision.

CNC Machining Solutions for California, USA

With extensive experience, we specialize in 5-axis machining, turning, and CNC milling, offering high-precision components with speed and stability across multiple industries.

| Rapid prototyping | Bridge Production | Massive Production |

|---|---|---|

| Smaller Tool Stock, More Axis | Big Tool Stock, More Axis | Bigger Tool Stock, Less Axis |

| Predominantly standard fixtures. | A few custom-made fixtures. | Custom Made Fixture |

| Highly precise with significant variance. | Highly precise with significant variance. | Accurate with slight variance. |

| Very expensive per Unit | expensive per Unit | Low per unit |

| LT: 1-4 business days | LT: 5-12 business days | Lead Time: 2-4 weeks |

| Capability: 1-50 pcs | Capability: 51-10,000 pcs | Capability: Above 10,001 pcs |

Surface Finishes for USA Customer

Tonza’s selection includes 20+ surface finishes designed to satisfy both functional and cosmetic requirements.

Brushing

Sand Blast

Polishing

Tumbling

Anodizing

Painting

Black Oxide

Powder Coating

Electroplating

Alodine

Passivation

Electroless Plating

Certifications & Quality Standards

Tonza produce CNC parts with precision consistency, meeting precision tolerances and supporting consistent assembly performa.

Machining is performed to ISO 2768 standard tolerances.

TonZa upholds a strong commitment to quality control procedures in its production process to ensure high quality products for its customers in California. Being ISO9001 certified for its quality management system, TonZa has demonstrated its dedication to maintaining high standards in all aspects of its operations. By adhering to strict quality control measures, TonZa can guarantee that its products meet the expectations and requirements of its customers in California.

In order to achieve this level of quality, TonZa regularly evaluates its production processes and implements improvements to enhance the overall quality of its products. Through continuous monitoring and analysis of its quality control procedures, TonZa can identify any potential issues or shortcomings and address them promptly to uphold its reputation for delivering excellence to its customers in California. With a focus on quality control, TonZa ensures that its products not only meet but exceed the expectations of its customers in terms of reliability, durability, and performance.

Other Machining Capabilities

From CNC machining to advanced manufacturing like vacuum casting and 3D printing, we serve California in USA.

Injection Molding

Sheet Metal Fabrication

High Pressure Die Casting

Vaccum Casting

3D Printing

CNC Machining Services Locations Near California, USA

{Tonza’s extensive experience in 5-axis machining, CNC milling, and turning allows us to delivering reliable, accurate, and trustworthy precision parts.}

FAQ

Here, we’ve listed some of the most common questions about CNC machining services for California, USA. “If you can’t find a satisfactory answer, feel free to contact us.“

California CNC machining providers offer services such as 3-axis and 5-axis milling, CNC turning, wire EDM, surface grinding, and precision drilling. Many companies also provide prototyping, rapid tooling, and full-scale production runs.

CNC machining supports California’s major industries including aerospace (especially in Los Angeles), medical devices (San Diego), automotive, electronics (Silicon Valley), robotics, renewable energy, and defense manufacturing.

CNC machine shops in California work with materials like aluminum, stainless steel, titanium, Inconel, copper, brass, PEEK, Delrin, ABS, and carbon fiber composites, suitable for both prototyping and production needs.

To get a quote, upload your CAD files (STEP, IGES, STL) along with any drawings and requirements to the provider’s website or email. California-based companies typically offer fast quoting, with responses within 24–48 hours.

Standard lead times range from 3 to 7 business days for prototypes, and 1 to 3 weeks for production runs. Many California CNC shops also offer same-day or next-day expedited services.

Yes, California has many CNC providers certified to ISO 9001, AS9100 (aerospace), ISO 13485 (medical), and ITAR, ensuring they meet strict industry-specific quality and compliance standards.

Definitely. California-based CNC companies are equipped to achieve high-precision tolerances down to ±0.0005 inches (±0.0127 mm), ideal for aerospace, medical, and semiconductor components.

Many shops in California offer engineering support, including design-for-manufacturing (DFM) consultations to optimize part designs for better performance, lower cost, and easier machining.

CNC machine shops in California provide a range of surface finishes, including anodizing, powder coating, bead blasting, passivation, electropolishing, black oxide, and custom coatings for corrosion resistance and aesthetics.

Choosing a California-based CNC machining company ensures access to advanced equipment, skilled machinists, fast lead times, and proximity to tech hubs, aerospace clusters, and innovation centers. It also supports local, high-quality manufacturing.

2 thoughts on “California ”

The quality of the product they delivered was top-notch. I was impressed with their attention to detail and precision. When it comes to machining services, Keep up the great work, guys!

The quality of their products is exceptional and their customer service is outstanding. The prices are reasonable for the level of expertise and precision they provide.