Order your custom manufacturing plan.

Online 4-Axis Machining Services

Get an instant online quote for your 4 axis CNC-machined parts with high quality and satisfication.

- Our in-house machine shop operates 24/7, ensuring quick turnaround times.

- Tolerances up to ±0.0004″ (0.01mm)

- Lead times as short as 1 day.

Start Your Project

STEP | STP | PRT | SLD | SAT | X_T | DWG | JPG | PNG | PDF

Max. file size: ≤10MB

When to Choose 4-Axis?

Choosing a 4-axis CNC machine depends on the complexity, precision, and efficiency required for your manufacturing process. It offers a middle ground between 3-axis and 5-axis machining, suitable for parts that require some rotational movement but not full multi-axis flexibility.

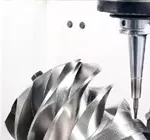

Complexity Beyond 3-Axis, But Not 5-Axis

- Ideal for: Parts that need angled features, slots, or holes on multiple faces.

- Why: 4-axis machines handle angled cuts and drilling on multiple faces with fewer setups, improving efficiency and precision.

- Example: Creating turbine blades, automotive parts, or certain medical devices.

When Cost Efficiency is a Priority things

- Ideal for: Medium-complexity parts that don’t justify the expense of a 5-axis machine.

- Why: 4-axis CNC machines are significantly cheaper than 5-axis machines, both in upfront investment and maintenance costs.

- Example: Low-volume production or prototyping where full 5-axis flexibility isn’t needed.

Reducing Setup Time for Multi-Faceted Parts

- Ideal for: Complex parts with multiple faces that would require multiple setups on a 3-axis machine.

- Why: A 4-axis machine can rotate the workpiece, machining several sides in a single operation.

- Example: Mold bases or fixtures with features on different planes.

Why Choose ours 4 Axis Machining Services?

delivering exceptional results through experience, dedication, and strategic thinking.

working closely with clients to understand their unique needs and goals

featuring the latest technology and advanced machinery to ensure precision, efficiency.

leveraging cutting-edge technology to manufacture intricate components

delivering exceptional value without compromising on quality or precision.

ensuring fast, efficient, and reliable production without compromising quality.

Capabilities of 4 Axis Machining Services

Our CNC machines deliver precision tolerances that meet industry standards, ensuring consistent accuracy and seamless component fit.

Maximum Diameter: 500mm or 19.7-inch

Max Length: 1800mm or 70.9-inch

Metal: 0.5mm or 0.02 in

Plastic: 1.0mm or 0.04 in

Metal: +/- 0.005mm (+/-0.0002 in)

Plastic: +/-0.025mm(+/-0.001 in)

4 bussiness days for most projects.

simple parts can be as fast as 1 day.

Advantages

Enables machining of more complex geometries compared to 3-axis machines.

Suitable for cylindrical, spiral, or angled cuts, ideal for parts like camshafts, turbines, and molds.

Can perform continuous cutting on multiple faces without manual repositioning, improving precision and efficiency.

Great for machining slots, holes, and other features on cylindrical or curved surfaces.

Cheaper and simpler to program than 5-axis machines.

Lower maintenance costs due to fewer moving parts.

Minimizes the need for manual repositioning, reducing operator error and improving consistency.

Disadvantages

Our CNC machines deliver precision tolerances that meet industry standards, ensuring consistent accuracy and seamless component fit.

Cannot handle undercuts or complex geometries that require simultaneous rotation on two axes (like in 5-axis).

Some features still require manual repositioning or multiple setups.

Requires more advanced CAM software and programming skills.

Higher learning curve than 3-axis machining.

While cheaper than 5-axis, 4-axis machines are still more expensive than 3-axis machines.

May not justify the cost for simple parts with low complexity.

Less precise for highly intricate parts that require continuous movement in multiple directions.

Vibration or backlash can be more pronounced in rotational movement.

FAQ

To provide clarity on our services, here are answers to frequently asked questions about prototyping and manufacturing.

4-axis machining involves the same three axes as 3-axis machining (X, Y, and Z) with the addition of a rotary axis (A-axis). This allows the workpiece to rotate during machining, enabling the creation of complex geometries with greater precision.

At TONZA, we can work with a wide range of materials, including aluminum, steel, stainless steel, brass, copper, titanium, and various plastics. Our capabilities cover both metal and non-metal components.

4-axis machining is widely used in industries such as aerospace, automotive, medical, electronics, robotics, and industrial equipment due to its ability to produce complex and precise parts.

Common applications include creating turbine blades, camshafts, impellers, complex enclosures, and other intricate components requiring precise rotational features.

We can accommodate parts of various sizes. Please contact us with your specific dimensions, and we can confirm feasibility.

Our 4-axis machining processes achieve high precision with tolerances as tight as ±0.01mm, depending on the complexity and material of the part.

With 4-axis machining, we can perform multiple operations in a single setup, reducing the need for repositioning and minimizing production time. This ensures faster lead times without compromising quality.

Yes, at TONZA, we specialize in rapid prototyping and low-volume production. Our 4-axis machining services offer flexibility for custom, precise parts with quick turnaround times.

Absolutely! We accept various file formats, including STEP, IGES, and STL. Our team can work with your designs to ensure optimal manufacturability.

You can request a quote by contacting us through our website or sending us your CAD files and project specifications. Our team will review your requirements and provide a competitive quote promptly.

Blog

Welcome to our blog, where we share insights into various manufacturing processes.