Order your custom manufacturing plan.

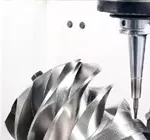

Online 3-Axis Machining Services

Get an instant online quote for your 3-axis CNC-machined parts with high quality and satisfaction.

- Our in-house machine shop operates 24/7, ensuring quick turnaround times.

- Tolerances up to ±0.0004″ (0.01mm)

- Lead times as short as 1 day.

Start Your Project

STEP | STP | PRT | SLD | SAT | X_T | DWG | JPG | PNG | PDF

Max. file size: ≤10MB

When to Choose 3-Axis?

If a part can be made with 3-axis machining without compromising quality or adding complexity, it is the most economical choice. However, if achieving complex angles, intricate features, or precision tolerances is required, 4-axis or 5-axis is preferable.

Simplicity

- Suitable for flat or moderately contoured parts where all features can be accessed from one orientation.

Lower Cost

- 3-axis machines are typically less expensive to operate, maintain, and program.

Efficient for High Volume

- Works well for high-volume production of simpler geometries

Shorter Lead Times

- Less time is spent on CAM programming and work-holding adjustments.

Why Choose ours 3 Axis Machining Services?

delivering exceptional results through experience, dedication, and strategic thinking.

working closely with clients to understand their unique needs and goals

featuring the latest technology and advanced machinery to ensure precision, efficiency.

leveraging cutting-edge technology to manufacture intricate components

delivering exceptional value without compromising on quality or precision.

ensuring fast, efficient, and reliable production without compromising quality.

Capabilities of 3 Axis Machining Services

Our CNC machines deliver precision tolerances that meet industry standards, ensuring consistent accuracy and seamless component fit.

Maximum Diameter: 500mm or 19.7-inch

Max Length: 1800mm or 70.9-inch

Metal: 0.5mm or 0.02 in

Plastic: 1.0mm or 0.04 in

Metal: +/- 0.005mm (+/-0.0002 in)

Plastic: +/-0.025mm(+/-0.001 in)

4 bussiness days for most projects.

simple parts can be as fast as 1 day.

Advantages

Lower machine and operation costs compared to 4/5-axis.

Easier to program and requires minimal fixture complexity.

Ideal for flat parts and high-volume production.

More common in shops, leading to shorter lead times.

Disadvantages

Our CNC machines deliver precision tolerances that meet industry standards, ensuring consistent accuracy and seamless component fit.

Difficult to machine complex geometries or deep cavities.

Requires repositioning the part, increasing cycle time and the chance of errors.

Achieving uniform surface quality on multi-faceted parts is challenging.

More setups can lead to accumulated tolerance errors.

FAQ

To provide clarity on our services, here are answers to frequently asked questions about prototyping and manufacturing.

3-axis machining operates along the X, Y, and Z axes, allowing the cutting tool to move in three directions to shape the material. It is ideal for flat or moderately contoured parts.

We work with a wide range of materials, including metals (aluminum, steel, brass), plastics, and composites.

We cater to industries such as automotive, aerospace, medical, electronics, and consumer products.

We can achieve tight tolerances typically ranging from ±0.01mm to ±0.05mm, depending on the material and design complexity.

Our 3-axis machines can accommodate parts up to [insert dimensions], ensuring flexibility for various project sizes. (You can specify dimensions if needed)

Lead times vary depending on the part complexity and quantity, but we strive to deliver prototypes and low-volume production parts within [insert typical timeframe].

Yes, we specialize in both rapid prototyping and low-volume production to help clients bring their designs to life efficiently.

-

-

We use advanced CNC machines, precise tooling, and rigorous quality inspections to ensure consistent and high-quality parts.

-

-

Yes, we offer a variety of finishing services such as anodizing, polishing, powder coating, and sandblasting to meet your aesthetic and functional requirements.

Simply contact us via our website, email, or phone with your CAD drawings and specifications. Our team will provide a competitive quote within 24–48 hours.

Blog

Welcome to our blog, where we share insights into various manufacturing processes.