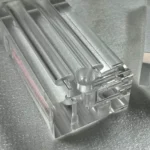

Custom Online Acrylic CNC machining services for you

Acrylic CNC machining services

- 24/7 operations in our machine shop guarantee fast lead times

- Tolerances up to ±0.0004″ (0.01mm)

- Lead times as short as 1 day.

Overview of Acrylic in manufacturing

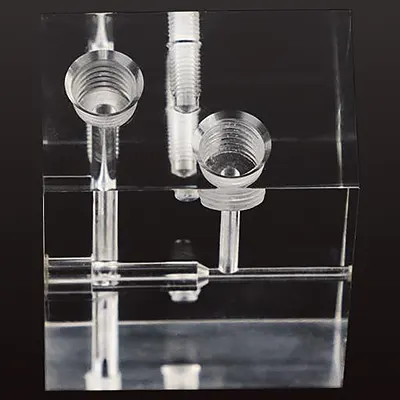

Our Custom Online Acrylic CNC Machining Service delivers high-precision machining for Acrylic parts, ensuring exceptional precision and craftsmanship. Using state-of-the-art CNC equipment, we expertly machine complex designs while offering fast delivery schedules and personalized solutions tailored to meet your unique project needs.

Properties

Acrylic is a versatile and durable synthetic material known for its transparency, flexibility, and resistance to UV rays. It is lightweight, easy to cut, shape, and dye, making it ideal for various applications in art, construction, and signage. Acrylic is also less prone to yellowing and fading compared to other plastics, maintaining its clarity and color over time. Its high impact strength and weather resistance make it suitable for outdoor use, while its thermal properties allow it to withstand extreme temperatures.

Parameters

Acrylic, a versatile thermoplastic material, is characterized by its high impact resistance, clarity, and UV stability. It is lightweight, durable, and easy to shape using heat. Moreover, it has excellent weatherability and is resistant to yellowing. Acrylic is commonly used in various applications such as signage, displays, furniture, and aquariums due to its optical clarity and ability to be easily fabricated. It has a wide range of colors and finishes available, making it a popular choice among designers and architects.

Precautions

Why Acrylic is ideal for CNC machining?

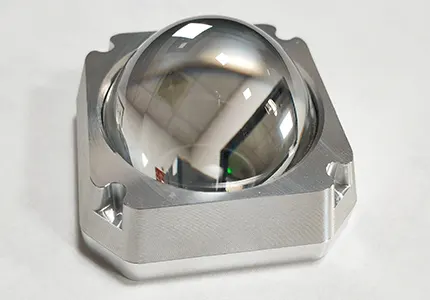

Acrylic is ideal for CNC machining due to its versatility and ease of use. This material is known for its durability and strength, making it perfect for intricate machining processes. Acrylic also offers high precision when cut, ensuring that the desired shapes and designs are achieved with accuracy. Additionally, acrylic is resistant to corrosion and can withstand harsh environmental conditions, making it a reliable choice for a wide range of applications. Its transparency and ability to be easily colored or painted further enhance its appeal for CNC machining projects. Overall, acrylic proves to be a superior material for CNC machining due to its numerous advantageous properties.

Benefits of working with acrylic at TONZA

Working with acrylic at TONZA offers numerous benefits for professionals in the industry. Acrylic is a versatile material that provides a wide range of design possibilities, making it an excellent choice for various applications. It is lightweight, durable, and easy to customize, making it ideal for creating unique and stunning pieces. Additionally, acrylic is known for its optical clarity, allowing for a high level of transparency that enhances the overall appearance of the final product. At TONZA, we provide expert guidance and support to help maximize the benefits of working with acrylic, ensuring a successful outcome for every project.

Why Choose ours Acrylic CNC machining services?

Each piece is fabricated to tight limits of ±0.01 mm, delivering a accurate fit to specification.

Tonza collaborate with reliable material providers to provide excellent standard inputs for your products.

Obtain fast and accurate DFM assessments to improve your design for fabrication and speed up production.

With in-depth market expertise, we deliver reliable the metal CNC machining solutions.

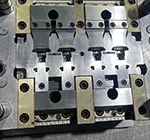

Capabilities of Acrylic CNC machining services

Our CNC machines deliver precision tolerances that meet industry standards, ensuring consistent accuracy and seamless component fit.

Tolerances

±0.05mm

Premium-grade tech solutions to provide you with premium-grade manufacturing output.

Max part size

500 mm x 500 mm

Elegantly designed innovation to provide you with engineered for excellence.

Min part size

5 mm x 5 mm

Vast hands-on experience, expertise in producing complex parts.

Lead Time

< 10 days

Well-coordinated team management, and lean operations with minimal downtime

Surface Finish

Ra 0.8-1.6 µm

Well-coordinated team leadership, and maximized output.

Wall Thickness

0.75 mm

Proven track record of success, capable of handling complex manufacturing challenges.

Acrylic Material Properties

Optimize your designs for manufacturability with our expert guidelines and feedback, ensuring the best results in CNC machining.

| Property | Value | Unit | Notes |

|---|---|---|---|

| Density | 1.18–1.20 | g/cm³ | Lightweight compared to glass |

| Tensile Strength | 65–75 | MPa | Good mechanical strength |

| Flexural Strength | 90–110 | MPa | High stiffness |

| Elongation at Break | 2–10 | % | Relatively brittle |

| Hardness (Rockwell) | M90–M100 | — | High surface hardness |

| Impact Strength (Izod) | 0.3–1.0 | kJ/m² | Much lower than polycarbonate (PC) |

| Melting Point | ~160 | °C | Softens before melting |

| Glass Transition Temperature | ~105 | °C | Becomes rubbery above this temperature |

| Maximum Service Temperature | ~80–90 | °C | Continuous use above this may degrade properties |

| Light Transmission | ~92 | % | Excellent optical clarity (higher than glass) |

| Water Absorption (24h) | ~0.3 | % | Low water absorption |

| UV Resistance | Excellent | — | Naturally UV-resistant, good for outdoor use |

| Chemical Resistance | Moderate | — | Resistant to dilute acids and alkalis; not resistant to solvents |

| Flammability | Burns easily, self-extinguishing grades available | — | Consider additives or coatings for flame resistance |

| Electrical Insulation | Good | — | Frequently used in electrical housings |

Commonly Used Acrylic Types

Our CNC equipment provide tight specifications that conform to market norms, securing consistent exactness and perfect piece integration.

| Type | Key Features |

|---|---|

| Impact-Modified Acrylic | Enhanced toughness, closer to polycarbonate, less brittle |

| UV-Resistant Acrylic | Improved durability in outdoor applications, prevents yellowing |

| Anti-Static Acrylic | Surface resists dust and static buildup – used in electronics |

| Flame-Retardant Acrylic | Contains additives to reduce flammability – used in aircraft and signage |

| Non-Glare (Matte) Acrylic | Diffuses light to reduce reflections – great for photo frames and displays |

| Abrasion-Resistant Acrylic | Coated for improved scratch resistance – often used in eyewear and panels |

| Colored or Tinted Acrylic | Wide range of colors, both transparent and opaque |

| Mirror Acrylic | Reflective coating on one side – lightweight alternative to glass mirrors |

| Light-Diffusing Acrylic | Used in LED panels and lighting to spread light evenly |

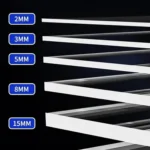

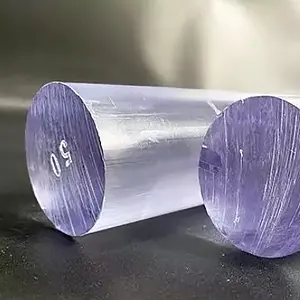

| Form | Typical Use Cases |

|---|---|

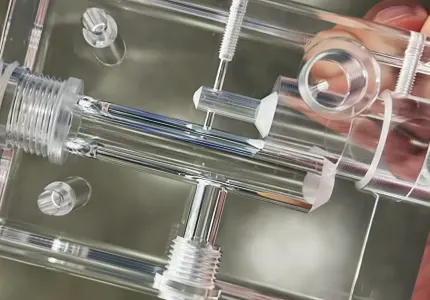

| Acrylic Sheet | Signage, display cases, glazing, furniture panels |

| Acrylic Rod | Lighting, decorative elements, point-of-purchase displays |

| Acrylic Tube | Aquariums, scientific equipment, display containers |

| Acrylic Film | Optical applications, electronics, overlays |

| Acrylic Pellets | Used in injection molding and extrusion processes |

| Type | Description |

|---|---|

| Cast Acrylic | Made by pouring liquid acrylic into molds; offers better clarity, strength, and scratch resistance. |

| Extruded Acrylic | Made by pushing acrylic through rollers; more economical and consistent, but slightly softer and less optically pure than cast acrylic. |

Surface Treatment of Acrylic

We deliver a wide range of CNC materials for precision-engineered components, including aluminum, steel, brass, plastics, and over 100 other materials.

Brushing

Polishing

Tumbling

Anodizing

Black Oxide

Electroplating

Powder Coating

Alodine

Passivation

Electroless Plating

Application Industries of Acrylic

From transportation to aviation, Tonza’s CNC milling satisfies the specific needs of diverse industries. We work with individual inventors, engineers, and enterprise companies, serving over 1,000 clients worldwide.

Choice Other Metal Materials Machining

Our CNC machines ensure industry-standard precision tolerances for repeatable precision and perfact part coordination.

Brass CNC machining services

Cooper CNC Machining Service

Aluminum CNC Machining Service

Stainless Steel CNC Machining Services

Mild Steel CNC Machining Services

Magnesium CNC Machining Services

Titanium CNC Machining Services

Standard for Metal

International standards such as DIN (Germany), GB (China), BS/EN (UK), AFNOR (France), UNI (Italy), SS (Sweden), UNE (Spain), JIS (Japan), AISI/SAE (USA), and ASTM are widely recognized. The differences among these standards are summarized in the chart below.

Choice Other Plastics Materials Machining

Our CNC machines deliver precision tolerances that meet industry standards, ensuring consistent accuracy and seamless component fit.

ABS CNC machining services

PMMA CNC Machining Service

Nylon CNC Machining Service

PC CNC Machining Service

PP CNC Machining Services

PET CNC Machining Services

PEI CNC Machining Services

POM CNC Machining Services

PTFE CNC Machining Services

PEEK CNC Machining Services

HDPE CNC Machining Services

UHMW CNC Machining Services

Standard for Plastic

Plastic materials are commonly subject to regulations and standards to ensure their safety, quality, and environmental impact. A leading organization that establishes such standards is the International Organization for Standardization (ISO).

FAQ about Acrylic

Get to know our Acrylic CNC Machining Services better through these frequently asked questions and answers.

We typically maintain tight tolerances of ±0.1 mm for CNC-machined acrylic parts. For high-precision applications, tighter tolerances can be achieved based on part geometry and requirements.

Yes, we provide polishing and finishing services such as flame polishing, vapor polishing, and hand buffing to enhance the clarity and surface smoothness of acrylic components.

Absolutely. With advanced 3-axis and multi-axis CNC machines, we can handle intricate acrylic designs, undercuts, slots, and fine features with high precision.

No, we support both rapid prototyping and low-volume production, meaning we can machine a single prototype or scale to hundreds of units depending on your needs.

Our expert machinists use optimized feeds, speeds, and sharp tooling to minimize risks of cracking or chipping. We also use coolant-free dry machining or air blasting to avoid stress on acrylic.

Lead times range from 3 to 7 business days, depending on part complexity, volume, and finishing requirements. Rush orders can be accommodated upon request.

Yes, we can machine threaded holes and also offer insert installation (such as brass threaded inserts) for assembly-ready acrylic components.

Yes. We offer CNC engraving and laser marking services for logos, text, or patterns on acrylic parts, providing both functional and aesthetic customization.

Simply upload your CAD files (STEP, IGES, or STL), specify the acrylic type and quantity, and our team will provide a fast and accurate quote within 24 hours.

We work with acrylic sheets ranging from 1 mm to over 50 mm in thickness. For very thick or thin acrylic components, we adjust our tooling and cutting strategy to maintain part integrity and precision.

CNC machining is ideal for thicker acrylic parts, precise pockets, edges, and threaded features where laser cutting may fall short. It also avoids heat-affected zones, making it preferable for parts that require tighter tolerances or post-machining assembly.

Yes, our engineering team provides Design for Manufacturing (DFM) feedback to help optimize your acrylic part for CNC machining—reducing cost, improving machinability, and ensuring better performance.