Many times, components must remain exposed to air for extended periods during use, making them prone to oxidation that shortens their service life and ultimately affects the entire equipment’s lifespan.

To address this issue, various metal surface treatment methods have been developed, with bluing being one of them.

This process forms a dense oxide film on the workpiece surface, preventing oxidation and extending the component’s service life.

The traditional bluing process involves dissolving sodium hydroxide (NaOH), sodium nitrite (NaNO₂), sodium phosphate (Na₃PO₄), and water to create a bluing solution.

Steel products are then immersed in this solution heated to 142–145°C. However, sodium hydroxide is highly corrosive, sodium nitrite is toxic, and the vapors generated during heating pose health hazards to operators.

This process is energy-intensive, time-consuming, and results in low labor efficiency.

Difference Between Blueing and Blackening

The resulting film typically appears blue-black or deep black, depending on oxidation conditions and workpiece composition..

Ferric oxide (Fe₃O₄) oxidized at high temperatures (approx. 550°C) exhibits sky-blue coloration, termed blueing.

Ferric oxide oxidized at low temperatures (approx. 130°C) appears dark black, termed blackening.

Blueing is commonly used in the defense industry, while blackening is prevalent in industrial manufacturing.

Recent optimizations of this surface treatment process enable cold-blue treatment at ambient temperatures (10–30°C) in blueing solutions, yielding compliant blue films within minutes.

Compared to traditional bluing processes, ambient-temperature bluing offers the following advantages:

Ambient-temperature series eliminates complex heating equipment, delivering significant energy savings;

Enhances work efficiency with flexible batch production to meet production demands at any time;

Improves corrosion resistance compared to conventional blackening;

Produces no harmful gases, protecting the environment;

Requires minimal investment with rapid results; features a simple process and convenient operation, reducing costs by approximately 20% compared to traditional methods.

Effectively overcoming the three major challenges of traditional bluing—high energy consumption, low efficiency, and environmental pollution—room-temperature bluing is increasingly adopted by heat treatment manufacturers.

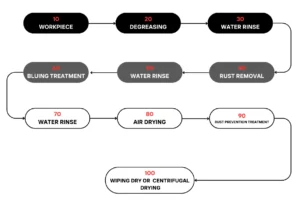

Process Flow

Workpiece → Degreasing → Water Rinse → Rust Removal → Water Rinse → Bluing Treatment → Water Rinse → Air Drying → Rust Prevention Treatment → Wiping Dry or Centrifugal Drying.

Degreasing

Prepare a 2%–10% aqueous solution of TJ30-1 powdered room-temperature multi-purpose metal cleaner. Degrease workpieces at room temperature or under heated conditions.

Select immersion, wiping, or brushing methods based on grease severity. Determine appropriate cleaning temperature and duration according to actual workpiece conditions.

Water Rinse

After degreasing, immerse workpieces in clean water for rinsing via immersion, wiping, or brushing. Dry workpieces thoroughly post-rinse.

Rust Removal

Based on production realities, rust removal typically involves minimal workload and can be performed using simple tools or abrasive materials. Common methods include scraping with a rust scraper or brushing with a wire brush.

Water Rinse

After rust removal, place the workpiece in clean water for rinsing. Methods include soaking, wiping, or brushing. Dry the workpiece thoroughly after rinsing.

Bluing Treatment

KB-91 rapid room-temperature steel bluing agent is used for bluing. Dilute the agent 1–2 times with water before use. Ensure workpieces are fully submerged during bluing, avoid stacking them, and agitate frequently. Processing time is typically 30–40 minutes.

Water rinsing and air drying

After blueing, immediately rinse the workpiece thoroughly. First rinse with hot soapy water for several minutes, then rinse with cold water. Finally, rinse with hot water and air dry.

Rustproofing

Use TY501 general-purpose water-based rust inhibitor. Before rustproofing, ensure all grease, dirt, and rust are thoroughly removed from the workpiece surface, then rinse with clean water until neutral.

Depending on required rustproofing duration, apply either undiluted solution or a 1–2 times water dilution via immersion or brushing. Processing time: 15 minutes. Processing temperature: Room temperature to 90°C.

Dry by wiping or spinning

Rust-proofed workpieces should be dried promptly by wiping or spinning. For workpieces requiring extended rust protection, wrap them in rust-proof paper first, then seal with plastic film.

Inspection Methods and Rules

The inspection of blued parts is essential to ensure the finish meets both functional and aesthetic requirements.

Appearance and surface

Appearance and surface quality are generally assessed by direct visual inspection.

Denseness Test

Thoroughly remove surface oil from finished parts using gasoline. Immerse parts in a 3% neutral copper sulfate solution for 40 to 60 seconds.

After surface moisture evaporates, inspect visually. If no red contact points appear, the bluing process is deemed satisfactory.

Blueing Film Cleaning Quality Inspection

After blueing and cleaning but before rustproofing, apply 1–2 drops of 10% phenolphthalein alcohol solution to the part surface. If the solution turns pink, cleaning is inadequate.

Advantages

The oxide process has many advantages different from others treatment duo to its special process.

Enhanced Rust Prevention

The presence of an oxide film effectively inhibits the formation of red rust (the corrosive rust that deteriorates steel) on the surface.

The porous ferric oxide protective film allows rust-preventive oil to saturate its pores, blocking moisture ingress and further enhancing rust resistance.

Additionally, post-treatment with rust-preventive oil maintains oil retention on the film surface, improving sliding performance for cutting tools and machine components.

Resistant to Peeling

Blackening is a surface treatment that induces a chemical reaction, transforming only the component’s surface into a different substance (the Fe₃O₄ protective film). This substance is extremely difficult to peel off.

Minimal Impact on Dimensional Accuracy

The film formation rate in the blackening process is relatively slow, resulting in a final film thickness of only about 1–2 μm.

The film forms from the surface inward. Since the processing temperature remains below 150°C, thermal deformation of parts is not a concern.

Aesthetically Pleasing Appearance

Blackening yields a finish resembling dyeing. Surface roughness remains unchanged before and after treatment. Glossy parts acquire a black lacquer-like sheen, while matte parts develop a non-reflective black surface.

Cost-Effectiveness

With low-cost processing solutions and no need for electrodes or fixtures, blackening is more economical than alternative surface treatments like plating or coating.

It can process components of varying sizes and shapes in a single operation, making it ideal for cost-effective treatment of diverse parts.

Disadvantages

Though the process has many advantages, but it is’nt unvoidable has those disadvantages.

Limited Rust Prevention

This process does not provide the same level of rust protection as zinc or nickel plating.

While it offers some rust resistance, it is unsuitable for parts used outdoors long-term, in high-humidity areas, or near the ocean.

Susceptible to Rust After Protective Oil Evaporates

The protective layer formed by magnetite itself offers weak rust resistance. As mentioned earlier, applying rust-preventive oil to the surface is typically necessary for enhanced protection.

However, if this oil evaporates completely, external moisture and air can penetrate the micro-pores within the magnetite layer, leading to the formation of red rust.

Incompatibility with Certain Materials

Blackening is a surface treatment process suitable for steel materials. However, components like quenched castings or wire-cut parts may sometimes turn reddish-black rather than completely black.

Alloy steels with higher chromium or nickel content may turn gray instead of black.

Thin Film Layer

While dimensional accuracy is minimally affected, this also implies relatively limited protective capability, unable to provide very strong resistance to wear or corrosion. Usage Notes

After oxidation treatment in the steel industry, corrosion resistance improves but protective properties remain inadequate.

Further treatment with soap solution, oil immersion, or chromic acid solution is required to enhance the film’s corrosion resistance and lubricity.

Steel oxidation is widely applied in mechanical parts, electronic equipment, precision optical instruments, springs, and weaponry. Regular oiling is still necessary during use.

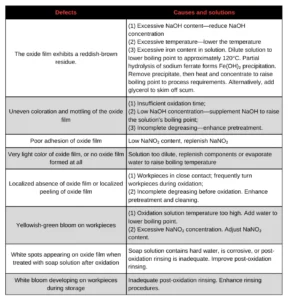

Common Defects and Treatment

Common bluing defects include uneven color from poor cleaning, rust spots or pitting from inadequate polishing, and rare flaking caused by bath contamination.

These issues are treated by stripping, re-cleaning, polishing, and repeating the bluing process, with strict bath control and surface preparation to prevent recurrence.

Conclusion

In conclusion, bluing is a highly effective surface treatment method for improving the durability and service life of components exposed to air, preventing oxidation and rust formation.

Traditional bluing processes, although effective, have limitations such as high energy consumption, hazardous chemicals, and health risks to operators.

However, the introduction of ambient-temperature bluing presents a more sustainable, energy-efficient, and safer alternative, offering quicker processing times and lower operating costs.

This method is increasingly favored by manufacturers due to its numerous benefits, including enhanced corrosion resistance, ease of operation, and environmental safety.

With continuous advancements in technology, ambient-temperature bluing is poised to become the go-to method for surface treatment, overcoming the challenges of traditional methods while maintaining high-performance standards.

FAQ

What are the advantages of ambient-temperature bluing over traditional bluing?

Ambient-temperature bluing offers several advantages, including significant energy savings, faster processing times, no harmful gas emissions, and reduced operational costs, making it an environmentally friendly and efficient alternative to traditional heating-based methods.

How does the bluing process protect metals from oxidation?

The bluing process creates a dense oxide layer on the metal surface, which acts as a barrier, preventing air and moisture from reaching the metal, thereby inhibiting oxidation and corrosion.

What industries benefit from using bluing for metal treatment?

Bluing is widely used in industries such as defense, manufacturing, automotive, and tool-making, where metal parts are exposed to the environment and require enhanced durability and corrosion resistance.

What are the main differences between bluing and blackening treatments?

Bluing and blackening are both oxidation processes, but bluing typically results in a blue-black oxide film, while blackening forms a black oxide film. Blueing is often used in defense, while blackening is common in industrial applications.

What are the risks associated with traditional bluing methods?

Traditional bluing methods involve the use of corrosive chemicals like sodium hydroxide and sodium nitrite, which pose health risks to operators due to toxic fumes and potential skin exposure. Additionally, the process requires high temperatures, leading to high energy consumption.

Can ambient-temperature bluing improve corrosion resistance?

Yes, ambient-temperature bluing significantly improves corrosion resistance compared to traditional blackening, making it ideal for parts exposed to moisture or harsh environments.

What is the typical film thickness formed during the bluing process?

The oxide film formed during bluing is typically very thin, around 1-2 micrometers. This thin layer ensures minimal impact on the dimensional accuracy of parts while offering protection from rust and corrosion.

How is the bluing process environmentally friendly?

Ambient-temperature bluing eliminates the need for complex heating equipment, reducing energy consumption. Additionally, it produces no harmful fumes, ensuring a safer working environment and reducing environmental impact compared to traditional methods.

What are some common defects in the bluing process and how can they be addressed?

Common bluing defects include uneven coloring, rust spots, and pitting. These issues can be addressed by improving surface cleaning, polishing, and strict bath control. If defects occur, the parts may need to be stripped, re-cleaned, and re-blued to achieve the desired finish.