Mirror EDM technology is an advanced machining method that utilizes the principle of electrical discharge to generate high-temperature, high-pressure physical effects on the workpiece surface, thereby achieving high-precision surface machining.

The origins of mirror-finish EDM technology date back to the 1950s, when electrical discharge machining (EDM) had already been widely adopted in metalworking.

However, the surface roughness values achieved were relatively high, failing to meet the demands of high-precision machining.

To address this challenge, researchers began exploring methods to enhance the surface quality of EDM processing, ultimately developing mirror-finish EDM technology.

Importance of Mirror EDM in Modern Manufacturing

Mirror EDM holds significant importance in industrial manufacturing due to its ability to achieve micron-level precision, meeting the demands of numerous high-accuracy applications.

It also offers high processing speeds, substantially boosting efficiency while saving time and costs.

Furthermore, it is adaptable to various conductive materials—both metallic and non-metallic—demonstrating high versatility and flexibility.

Most importantly, mirror EDM enables high-precision machining of workpiece surfaces, delivering superior surface quality with minimal defects like scratches or burrs, thereby enhancing part quality and reliability.

As technology and machining equipment continue to evolve, mirror EDM will undergo iterative development, providing higher-quality, more efficient machining solutions across industries.

Purpose and Significance

The research objectives and significance of mirror EDM encompass the following key aspects:

Enhancing Machining Precision

Mirror EDM achieves micron-level machining accuracy, enabling the production of extremely small and complex shapes to meet high-precision requirements.

This is crucial for manufacturing components demanding exact dimensions and forms, such as precision molds and micro-optical elements.

Enhancing Machining Efficiency

Compared to traditional mechanical machining methods, mirror EDM offers superior efficiency.

It enables simultaneous processing of multiple workpieces and operates without restrictions on material hardness, making it suitable for various metallic materials and conductive non-metallic materials.

This significantly contributes to improving production efficiency and shortening processing cycles.

Expanding Processing Scope

Mirror EDM can also process materials difficult to machine conventionally, such as high-hardness and brittle materials.

It enables precision machining of these materials without inducing thermal stress or deformation, thereby enhancing material performance and service life.

Exploring New Application Fields

For instance, in micro-nano fabrication, mirror EDM enables the production of microdevices and microfluidic chips.

Furthermore, mirror EDM finds applications in precision medical devices, aerospace, and electronics, driving advancements across these industries.

Principles of Mirror Electro-Discharge Machining Technology

The fundamental principle of electro-discharge machining (EDM) lies in harnessing the high temperature, high pressure, and high-speed impact force generated by electrical discharges.

By creating a discharge gap on the workpiece surface, current flows between the electrode and workpiece through this gap, producing high-temperature plasma.

This process causes the surface material of the workpiece to instantly melt, vaporize, and dissolve, thereby achieving non-contact machining.

EDM Discharge Process and Material Removal

During machining, the electrode and workpiece are connected to the positive and negative terminals of the power supply, respectively.

Electro-discharge oil is filled into the gap to be machined. Through a pre-set machining program and the machine’s automatic gap control system, the electrode is fed toward the workpiece.

When the gap between the electrode and workpiece reaches a predetermined distance, a pulsed voltage ionizes the working fluid, initiating spark discharge.

Massive thermal energy concentrates instantaneously within the narrow gap channel.

Rapid temperature rise accompanied by abrupt pressure changes causes a small amount of metal on the workpiece surface to melt or vaporize.

This molten metal enters the EDM oil, solidifies into metallic particles, and is carried away by the oil. This process creates microscopic pits on the workpiece surface.

Upon completion of the discharge, the machine tool retracts the electrode, allowing the spark-discharge oil in the gap to return to its insulating state.

When the machine tool advances the electrode again, it triggers the next pulse voltage, initiating another discharge machining cycle, and the process repeats.

Mirror EDM for High-Precision Surface Finish

Mirror EDM is a specialized form of electrical discharge machining. Its principle involves controlling the discharge gap between the electrode and workpiece.

The high-temperature plasma generated when current passes through this gap creates microscopic pits on the workpiece surface.

Through minute displacements of the electrode relative to the workpiece, the discharge gap shifts position, causing discharges at different locations.

This process gradually fills the pits, ultimately forming a smooth surface.

Through repeated discharges and displacement, high-precision machining of the workpiece surface is achieved, meeting mirror-like surface roughness requirements. The specific machining process is as follows.

Formation of the Discharge Gap Between Electrode and Workpiece

In mirror EDM, the discharge gap between the electrode and workpiece is extremely small, typically ranging from several micrometers to tens of micrometers. Controlling this gap size regulates the discharge energy and shape.

Current flows through the discharge gap

When current passes through the gap, gas ionizes due to resistance and voltage, forming plasma. This plasma reaches extremely high temperatures, potentially exceeding thousands or even tens of thousands of degrees Celsius.

Plasma Impact on the Workpiece Surface

The high temperature and high-speed impact force of the plasma cause the surface material of the workpiece to instantly melt, vaporize, and dissolve.

Simultaneously, ions and electrons within the plasma undergo chemical reactions with the surface material, inducing both physical and chemical changes.

Repeated Discharges and Displacement

By controlling minute displacements between the electrodes and the workpiece, discharges occur at different positions within the gap.

Through repeated discharges and displacement, pits and grooves on the workpiece surface are gradually filled, ultimately forming a smooth surface.

Technical Characteristics

Mirror EDM technology possesses the following characteristics:

High Precision

Mirror EDM achieves exceptionally high machining precision, attaining sub-micron surface roughness values and dimensional accuracy.

This makes it widely applicable in fields requiring high-precision surfaces, such as optical instruments and mold manufacturing.

High Efficiency

Mirror EDM offers superior machining efficiency. The high temperatures and rapid impact forces generated by electrical discharges enable completion of the machining process within a very short timeframe.

This provides advantages for mass production and urgent machining requirements.

Wide Range of Applications

Mirror EDM technology is suitable for processing various materials, including metals, non-metals, and composite materials.

It can effectively machine both high-hardness materials like steel and iron, as well as brittle materials such as ceramics and glass.

Superior Surface Quality

Mirror EDM achieves high-quality surface finishing. The intense heat and high-speed impact of electrical discharges cause material on the workpiece surface to instantly melt, vaporize, and dissolve.

This process eliminates surface defects and residual stresses, resulting in a flat, smooth finish.

High Flexibility

Mirror EDM technology offers exceptional flexibility. By adjusting parameters such as the discharge gap between the electrode and workpiece, current intensity, and discharge duration, it can process components of varying shapes and dimensions.

Additionally, precise control over minute displacements between the electrode and workpiece enables the machining of complex geometries.

Application Fields

The application fields of mirror EDM technology are as follows.

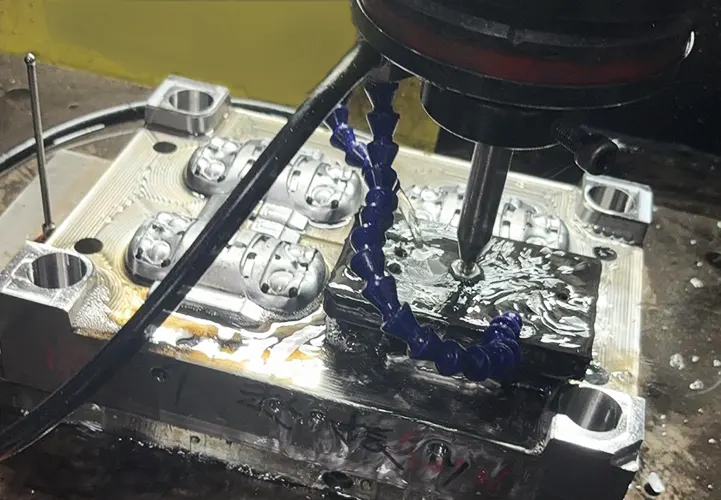

Mold Manufacturing

Mirror EDM technology can be used to manufacture high-precision, high-quality molds.

By generating micro-pits on the surface of metal workpieces through electrical discharge, it achieves machining and engraving of the workpiece.

This processing method enables the production of extremely fine molds that meet the dimensional accuracy and surface quality requirements in mold manufacturing.

Aerospace

The aerospace sector demands exceptionally high precision and quality for components.

Mirror EDM enables high-precision machining of various materials, making it suitable for manufacturing aerospace parts such as engine components and equipment housings.

Automotive Manufacturing

The automotive manufacturing sector also demands high precision and surface quality for components.

Mirror EDM technology can be used to manufacture various automotive parts, such as engine and transmission components.

Electronics Industry

The electronics industry has stringent requirements for processing micro-components. Mirror EDM technology can be employed to manufacture various electronic components, such as chips and circuit boards.

Medical Devices

Medical devices demand exceptional precision and surface quality.

Mirror EDM technology can be employed to manufacture various components in this field, such as surgical instruments and artificial joints.

Instrumentation and Metrology

Mirror EDM technology can be utilized to produce various components for the instrumentation and metrology sectors, including optical instruments and precision measuring devices.

Development Trends

The development trends for mirror EDM technology are as follows.

High-Precision Machining

With continuous technological advancement, mirror EDM will evolve toward higher precision, enabling finer machining and superior surface quality.

Multifunctional Machining

Mirror EDM will develop additional capabilities to meet diverse machining demands.

Examples include processing holes of various shapes and machining complex curved surfaces.

Automation and Intelligence

Driven by advancements in automation and intelligent technologies, mirror EDM will integrate robotic systems, automated control systems, and artificial intelligence.

This integration will automate and intelligentize the machining process, enhancing production efficiency and machining quality.

New Material Processing

The emergence of new materials continuously elevates demands on machining technologies.

Mirror EDM technology will continually adapt to these demands, developing processing methods and techniques suitable for diverse new materials.

Environmental Protection and Energy Efficiency

During processing, mirror EDM technology minimizes material waste and energy consumption.

Future focus will intensify on environmental protection and energy conservation, reducing negative environmental impacts through improved processing techniques and equipment.

Challenges and Solutions

The challenges and solutions for mirror EDM technology are outlined below.

Thermal Effects and Thermal Deformation During Processing

Solutions:

① Control discharge parameters such as pulse current and discharge duration to minimize thermal effects.

② Use cutting fluids to cool the workpiece and electrodes, reducing temperatures.

③ Select suitable workpiece materials, such as those with high thermal stability, to minimize thermal deformation.

Electrode Wear and Service Life Issues

Solutions:

① Use high-quality electrode materials, such as copper or copper-molybdenum alloys, to enhance wear resistance.

② Control discharge parameters like pulse current and discharge duration to minimize electrode wear.

③ Conduct regular inspections and replacements to maintain machining quality and extend electrode lifespan.

Discharge Stability and Surface Quality Issues

Solutions:

① Optimize discharge parameters like pulse current and discharge duration to improve discharge stability and surface quality.

② Employ high-precision electrodes and process equipment to enhance machining accuracy and stability.

③ Regularly clean and maintain equipment to ensure consistent machining quality and stability.

④ Conduct pre-processing planning and trials to determine optimal machining parameters and process flows.

Advantages and Disadvantages

Advantages

Mirror EDM technology is suitable for machining workpieces of various hardness levels and complex geometries, offering the following primary advantages:

(1) High Precision:

Mirror EDM achieves micron-level machining accuracy, making it ideal for high-precision components.

(2) Complex Geometry Machining:

This technology can process intricate workpiece shapes, including internal/external contours and cavities.

(3) Material Hardness Flexibility:

Capable of machining materials across a wide hardness range, including metals, ceramics, and alloys.

(4) Non-Contact Machining:

As a non-contact process, it avoids inducing mechanical stress or deformation on the workpiece surface.

(5) High Efficiency:

Supports simultaneous machining of multiple workpieces, enhancing overall productivity.

Disadvantages

However, mirror EDM also presents the following limitations and drawbacks.

(1) Relatively slow processing speed:

Each discharge removes only a minute amount of material, resulting in comparatively slow processing rates.

(2) Limited surface quality:

Thermal effects and deformation during discharge can occur, potentially yielding surface quality inferior to other machining methods for certain materials.

(3) Electrode wear and lifespan issues:

Electrodes experience wear during discharge and require periodic replacement, increasing costs and workload.

Future Development Directions

With the advancement of manufacturing and growing demand for high-precision components, mirror EDM holds broad prospects for development. Future directions include:

Enhancing Machining Speed

Optimizing discharge parameters and improving equipment to increase EDM speed and boost production efficiency.

Improving Surface Quality

Researching and developing new electrode materials, cutting fluids, etc., to reduce thermal effects and deformation, thereby enhancing surface finish quality.

Adaptive Control Technology

Incorporating adaptive control systems to monitor and adjust discharge parameters in real time, thereby improving machining stability and precision.

Integrated Machining Techniques

Combining mirror EDM with other processing methods, such as combined machining or multi-station processing, to accomplish more complex machining tasks.

Conclusion

This paper explores the principles, characteristics, application domains, and development trends of mirror EDM technology, summarizing its advantages and limitations.

Solutions are proposed for challenges encountered during processing, and integration with other machining methods enables the fabrication of workpieces with varying hardness levels and complex geometries.

Mirror EDM technology holds broad application prospects in high-precision component manufacturing.

With ongoing technological advancements and innovations, its machining speed and surface quality are poised for further enhancement.

FAQ

What Is Mirror EDM Technology and How Does It Differ From Conventional EDM?

Mirror EDM (Mirror Electro-Discharge Machining) is an advanced EDM method that focuses on achieving ultra-smooth, mirror-like surface finishes. Unlike standard EDM, which often leaves higher surface roughness, mirror EDM uses precise control of the discharge gap, current, and electrode movement to minimize defects like scratches and burrs.

How Does Mirror EDM Achieve High-Precision Machining?

Mirror EDM generates high-temperature plasma in a microscopic discharge gap between the electrode and the workpiece. Controlled discharges melt and remove material in micrometer-sized layers, allowing manufacturers to achieve micron-level dimensional accuracy and sub-micron surface roughness.

What Materials Can Be Processed Using Mirror EDM?

Mirror EDM is highly versatile and can process both metallic and conductive non-metallic materials. It is ideal for machining hardened steels, carbide, titanium alloys, ceramics, and even brittle materials such as glass—making it suitable for industries like aerospace, medical devices, and precision molds.

What Are the Key Advantages of Mirror EDM in Modern Manufacturing?

Major benefits include:

Micron-level precision for intricate geometries.

Ability to machine hard or brittle materials without mechanical stress.

Superior surface quality with minimal defects.

High flexibility for different shapes and dimensions.

Cost-effective efficiency for mass production.

What Are the Common Applications of Mirror EDM Technology?

Mirror EDM is widely used in:

Mold manufacturing for high-precision injection molds.

Aerospace components requiring dimensional accuracy.

Automotive engine and transmission parts.

Electronics for micro-components like chips and circuit boards.

Medical devices such as surgical tools and implants.

Instrumentation including optical lenses and metrology devices.

How Does the Discharge Gap Affect the Surface Finish in Mirror EDM?

The discharge gap—typically a few to tens of micrometers—controls the energy released during each pulse. A smaller, stable gap reduces thermal damage, enabling uniform removal of microscopic material layers and producing a smoother, mirror-like finish on the workpiece surface.

What Are the Limitations or Challenges of Mirror EDM?

Key challenges include:

Slower processing speeds compared to conventional cutting.

Electrode wear that increases costs and requires maintenance.

Potential thermal deformation that may affect delicate materials.

These challenges can be mitigated by optimizing discharge parameters, using high-quality electrodes, and improving cooling techniques.

How Does Mirror EDM Improve Efficiency Compared to Traditional Machining?

Mirror EDM removes material without physical contact, allowing simultaneous machining of multiple workpieces and handling of extremely hard or brittle materials. This reduces the need for additional finishing processes, shortens production cycles, and improves overall productivity.

What Future Trends Are Shaping the Development of Mirror EDM Technology?

Emerging trends include automation and AI-driven process control, integrated hybrid machining techniques, and environmentally friendly solutions that reduce energy consumption and material waste. These advances aim to boost speed, precision, and sustainability.

Is Mirror EDM Cost-Effective for High-Volume or Precision-Critical Industries?

Yes. Although initial equipment and electrode costs can be higher, Mirror EDM often reduces total manufacturing expenses by minimizing secondary finishing, scrap, and downtime. Its efficiency and precision make it especially cost-effective for aerospace, medical, and electronics industries where quality is critical.