In modern manufacturing, laser processing of materials is one of the most active areas of research in material processing technology, with laser cutting accounting for over 70% of all laser processing applications and widely used in industries such as machinery, automotive, and aerospace.

Compared to traditional cutting methods, laser cutting offers advantages such as a wide cutting range, narrow cutting gaps, minimal heat-affected zones, and high processing flexibility.

Advantages of Laser Cutting

These advantages are particularly evident in new product development and mass production, where laser cutting demonstrates its high-speed, efficient, high-precision, and cost-effective characteristics.

Laser cutting produces very narrow cutting gaps and minimal deformation of the workpiece.

Mechanism and Material Interaction

When the laser beam is focused to an extremely small point, it generates extremely high energy density at the focal point.

At this point, the input energy far exceeds the energy reflected, conducted, or dissipated by the material, causing the material to rapidly heat up until it vaporizes, forming vapor holes.

As the laser beam moves relative to the material, the continuously formed holes form a narrow cutting gap.

Since the heat-affected zone at the cutting edge is small, the thermal deformation of the workpiece can be neglected.

With the rapid development of laser processing technology, laser cutting has replaced a significant portion of traditional sheet metal processing methods in manufacturing, such as punching, shearing, cutting, and turning.

While the change in processing methods and the implementation of new processes have brought significant efficiency improvements to enterprises, they have also raised new issues.

Challenges and Risks of Non-Optimized Laser Cutting

Although production efficiency has improved, if the processing technology is not optimized through research, it will result in significant waste and losses.

Laser cutting is a thermal processing technique that combines material melting and vaporization, with highly complex processing procedures and technical challenges, thereby involving numerous influencing factors.

In addition to inherent factors such as equipment condition and processed materials, various variables in actual operation can significantly impact the final processing quality.

If the cutting process is improperly designed, cutting quality is difficult to control, and batch-level scrap issues may arise.

When programming laser cutting, how to select the optimal process scheme to ensure both part cutting quality and improve sheet material utilization.

This article analyzes how the following seven factors impact processing quality and sheet material utilization.

It bases this analysis on issues encountered in actual cutting and the characteristics of laser cutting. The goal is to guide daily production work.

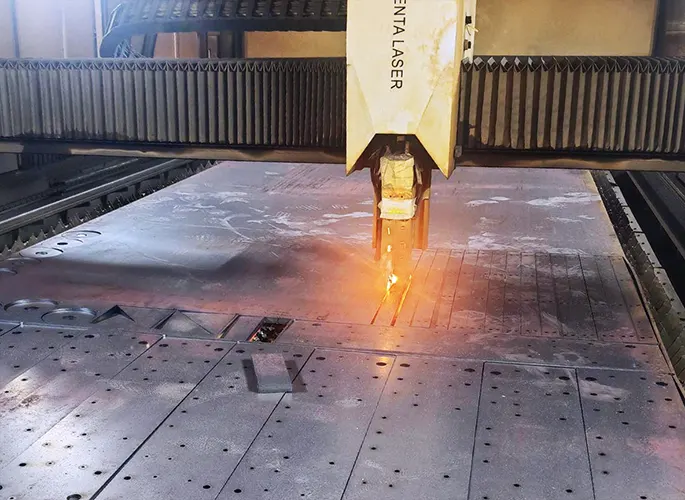

Laser cutting

Laser Cutting Punching Points and Lead Wires

Punching Point Settings

All known thermal cutting technologies generally require a small hole to be pre-punched in the raw material. In laser cutting, this pre-punched small hole is referred to as a punching point.

During the laser cutting process, the material is continuously exposed to the laser beam, forming a tiny depression at the center of the beam.

This depression is then rapidly blown away by an auxiliary gas flow coaxial with the laser beam, creating a small hole.

This hole is similar to the threading hole in wire cutting, and the laser beam uses this hole as the starting point for cutting the part’s outer contour and inner hole profile.

In laser cutting processes, the punch point refers to the location where the laser beam first penetrates the material, serving as the starting point for subsequent cutting operations.

Typically, before cutting the complete contour of a workpiece, the laser creates a small hole on the sheet as the starting point.

» Precision Considerations for Piercing Point Placement

For applications with lower precision requirements or where precise cutting is not necessary, the piercing point can be directly set on the part’s contour line.

However, during the piercing process, the laser requires preheating, which creates a heat-affected zone around the piercing point.

Additionally, the diameter of the piercing point is often larger than the standard cutting seam width, resulting in lower processing quality and surface roughness in this area compared to the normal cutting path.

Therefore, when high-precision processing is required, you typically set the piercing point in the scrap area outside the workpiece contour near the starting point of the cutting path.

This approach helps avoid affecting the finished product’s quality and ensures the overall cutting quality and precision of the workpiece.

Properly determining the piercing position is critical for ensuring the cutting quality of the part edges.

» Impact of Piercing Point Position on Material Utilization

Additionally, the distance between the piercing point and the starting point of the cutting path must be carefully set.

Laser cutting is costly. If you set this distance too long, it will increase the outer dimensions of the part.

This increase reduces the number of parts you can process from a sheet of material with a certain width. Consequently, it lowers the utilization rate of the sheet material per unit area;

However, the laser beam requires some time to stabilize its parameters after it is generated.

Therefore, you cannot set the distance between the punch point and the part contour too short.

If you do, the local cross-section near the punch point on the part contour may have poor cutting quality.

Additionally, if the thermal flow effects of laser cutting sheet metal are considered, the situation becomes more complex, and selecting a reasonable hole position is crucial.

Lead-in Settings

During laser cutting, from the moment the beam penetrates the sheet metal until it cuts into the part’s contour, the cutting speed undergoes a sudden change in the vector direction, almost forming a 90° angle change.

Specifically, the laser direction rapidly changes from nearly perpendicular to the cutting path to align with the tangential direction of the contour, resulting in an angle of 0° between the two.

This sudden directional change causes the cutting edge to become relatively rough.

This occurs because the laser’s direction of travel undergoes a drastic change within an extremely short timeframe. Therefore, this aspect must be considered when performing laser cutting of parts.

» Surface Quality and Piercing Point Selection

If there are no special requirements for the surface roughness of the cut surface, the cutting program can typically be allowed to automatically generate the piercing points.

However, if a higher surface quality is required, the initial cutting position of the laser must be adjusted during the programming stage, i.e., the piercing point location must be manually selected.

This is done to ensure that the surface of the cut part meets the required precision standards.

» Lead-in Line Design and Its Importance

During sheet metal cutting, to ensure smooth seam alignment and prevent burn damage at the starting end, a transition line is often drawn between the piercing point and the cut seam, referred to as a lead-in line.

Additionally, the lead-in line should not be placed in areas such as sharp corners where heat dissipation is difficult.

The connection between the lead-in line and the cut seam should be as smooth as possible to ensure stable machine movement and avoid burn damage caused by angular pauses.

» Purpose and Optimization of the Lead-in Line

In summary, the purpose of setting the lead line is to ensure the laser beam quality remains stable before starting the effective cutting of the part contour.

This practice helps avoid the drilling point’s impact on the overall cutting quality of the part contour.

Based on production experience, it has been observed that using a straight lead line when cutting thicker parts can cause burn damage at the starting point.

Using a curved lead line when cutting thinner parts can extend processing time and reduce efficiency.

while using an arc lead line yields results intermediate between the two.

Therefore, the selection of the lead line should also be based on the material and thickness of the sheet metal, with optimal data obtained through repeated testing.

Circular Auxiliary Cutting Path

During laser cutting of sheet metal, especially when using auxiliary gases like air, nitrogen, or other inert gases, you may observe additional burrs or deformation on the back side of the material.

These issues often occur at sharp corners or at the end of the processing area.

Speed Changes at Sharp Corners and Their Effects

The cutting head moves at a speed set by the CNC program. However, at sharp corners or at the end of the processing area, the moving axis suddenly changes direction.

Because of the processing equipment’s characteristics, the processing speed slows down in these areas.

In such cases, the processing equipment keeps the laser power settings fixed.

As a result, when the processing speed slows down, the balance between laser power and speed is disrupted, causing excess output power.

This disruption leads to the formation of additional burrs or deformation.

Reducing Maximum Cutting Speed to Minimize Burrs

To address this issue, you can reduce the maximum cutting speed in the laser cutting parameter settings.

This action minimizes the difference between the maximum and minimum cutting speeds throughout the entire processing process.

Here, whether the cutting speed is at its maximum or minimum, it should be set with the premise of minimizing burr generation.

The drawback of this method is that the average speed decreases, prolonging the entire processing cycle and reducing production efficiency.

Using Auxiliary Overtravel Trajectories to Maintain Speed

Another approach is to modify the part contour trajectory by designing auxiliary overtravel trajectories to prevent the cutting speed from decreasing at sharp corners or end positions.

For example, you can design the program to perform a circular overtravel process at sharp corners.

After you process the part contour trajectory with a circular overtravel, the program converts the trajectory at points of abrupt directional changes into a gradually changing smooth circular cutting path.

This method effectively avoids excessive output power caused by sudden drops in cutting speed.

Using a circular overtravel program at the end of inner hole processing can also cut inner holes without reducing the cutting speed.

Setting up an auxiliary cutting path is an important process measure to ensure the cutting quality of the part’s outer contour.

Managing Heat Concentration with Ring-Shaped Auxiliary Cutting Paths

Laser cutting achieves the cutting effect by melting and vaporizing the material through thermal energy.

However, if heat dissipation is poor and heat accumulates, it may affect the local processing quality of the part, especially at sharp corners, where this is particularly noticeable.

Sharp corners are prone to damage due to excessive heat concentration, leading to reduced processing accuracy, or even burning or deformation of the sharp corners.

To address this issue, a closed ring-shaped auxiliary cutting path can be added at the sharp corners of the part’s outer contour.

This design effectively improves heat dissipation in the sharp corner areas, preventing excessive heat concentration and ensuring cutting accuracy.

The primary function of the ring-shaped auxiliary path is to achieve high-quality cutting of the sharp corners of the outer contour without adjusting parameters such as laser power and cutting speed.

Laser Cutting Optimization Layout

In laser cutting applications for sheet metal, the design scheme for arranging parts on the sheet directly impacts material utilization and production cycles.

An optimal layout not only significantly improves material utilization but also effectively reduces production time.

By arranging multiple parts on the sheet in a nested layout, material waste can be minimized. Therefore, optimizing the layout is crucial.

Optimized layout refers to the reasonable arrangement of the contours of parts to be cut on a sheet of a given size to maximize sheet utilization.

Additionally, during the optimization process, you must consider factors such as pre-layout preparation, selection of cutting processes, and cutting efficiency.

You should pay special attention to issues related to continuous cutting of parts and shared edge cutting technology.

The core objective of optimization is to fit the maximum number of parts on a sheet of material with a specified size.

Alternatively, it aims to arrange a certain number of parts on the smallest possible sheet area. Both approaches help maximize material utilization.

Standard Layout

Standard layout types are divided into 0° layout and 90° layout.

Offset Layout

When product shapes are irregular, single-piece layout results in low utilization and material waste.

By rotating and combining workpieces, utilization can be improved.

Offset layout types are divided into single-direction offset layout and double-direction offset layout.

Mixed Layout

When material utilization cannot be optimized through standard methods (standard layout or offset layout), mixed layout should be considered to improve material utilization.

Mixed layout is categorized into single-part mixed layout and multi-part mixed layout.

(1) Single-part mixed layout.

(2) Multi-part mixed layout.

When performing multi-workpiece mixed layout, the following prerequisites must be considered:

① The materials must be the same;

② The material thickness must be the same;

③ The production must be coordinated (the product quantity ratio must be consistent).

Three types of parts need to be produced on the same sheet of material. The larger part, which requires a 45° direction cut due to subsequent bending processes, can be considered the main part.

Due to the irregular shape of the main part, small parts (sub-parts) are embedded using gap scrap material to improve sheet utilization.

In actual laser cutting sheet processing, cutting quality is related to the complex geometric shape of the parts.

To improve sheet utilization and reduce scrap, nesting is often used during layout, meaning that smaller parts should also be placed inside the “large holes” of parts with holes.

For laser cutting of parts in pre-arranged sheet metal layouts, the optimal cutting sequence should proceed from the interior to the exterior, first cutting the parts within the holes and then those outside the holes.

To prevent sheet metal deformation from affecting processing accuracy, when cutting sheet metal with parts of different sizes, smaller components should be processed first, followed by adjacent larger components.

This approach also helps prevent sheet metal deformation.

Common-edge Cutting

In laser cutting, the clearance (spacing) between parts affects material utilization.

Common Edge Cutting for Straight-Line Shapes

If the processed shapes mainly consist of straight lines, you do not need to apply laser beam radius compensation.

When the precision tolerance stays within the laser cut seam width range, you can try the common edge cutting method.

This method not only improves material utilization and reduces costs but also saves processing time for the straight edges of the common edge sections, significantly enhancing processing efficiency.

Program Compilation for Repetitive and Mixed Shapes

For repetitive processing of parts with the same shape, such as rectangular parts, the processing program is also simple to compile; simply stack them in an array.

For processing multiple parts with different shapes, combine the processing of multiple shapes into a single block, then stack the block in a simple array.

You can combine two or more parts with shared edges into a single assembly. For large-scale regular shapes, you can maximize the shared edges to significantly reduce cutting time and save raw materials.

Shared-edge cutting falls into three categories: 0° shared edges, 90° shared edges, and simultaneous 0° and 90° shared edges.

The advantages of shared-edge cutting are evident, as it improves material utilization and saves processing time.

Challenges and Limitations of Shared-Edge Cutting

However, in actual production, shared-edge cutting is challenging.

Both sides of the cut seam are parts that need processing, so it is difficult to control the width of the cut seam and the position of the lead lines.

These challenges can cause significant dimensional errors in the parts.

Therefore, it is not suitable for the processing of precision parts.

Spacing Requirements for Parts with Curved or Compensated Contours

When processing shapes that require compensation settings or cannot be processed using common edge cutting (typically those with curved outer contours), a certain width of spacing must be set between parts.

Generally, the width of this spacing varies depending on the thickness of the processed sheet material. The reference standards for CNC program compilation are as follows:

- When the sheet thickness is 1mm, the spacing between parts is 5mm;

- When the plate thickness is 2mm, the spacing between parts is 4mm;

- When the plate thickness is 3mm to 6mm, the spacing between parts is 1 times the plate thickness;

- When the plate thickness is 6mm to 12mm, the spacing between parts is 6mm;

- When the plate thickness exceeds 12mm, the spacing between parts is half the plate thickness.

Interactive Laser Perforation

When parts have irregular internal holes that are prone to warping and colliding with the laser head, you can set intersecting laser paths within the internal holes.

You can also use this method when the internal holes are too large to fall out easily.

These intersecting paths perforate the target internal holes and form many small fragments with relatively regular shapes. These fragments are easier to remove.

Setting up interactive laser perforation of internal holes enhances the safety of the processing process.

Laser Beam Radius Compensation

Due to the natural divergence of the laser beam, even after focusing, it cannot form an ideal geometric point but instead forms an approximate circular spot with a certain size.

When performing precision laser cutting of parts, radius compensation of the laser path is necessary to ensure cutting accuracy.

In actual operation, the minimum diameter of the laser spot typically ranges from 0.1 mm to 0.5 mm.

To achieve automatic compensation, you offset the center trajectory of the laser beam by half the spot radius relative to the theoretically defined contour set by the program.

The system then processes this offset trajectory accordingly.

Empty stroke processing

During laser cutting of sheet metal, you need to maintain a constant distance between the laser beam focus and the sheet metal surface (i.e., the defocus amount).

To achieve this, engineers typically install a follow-up system, such as a capacitive sensor, on the nozzle of the laser cutting head.

However, this method also presents new challenges.

When the cutting path passes through an area where the workpiece has already been cut and dropped, the follow-up system tries to keep the focus position unchanged.

This action causes the cutting head to suddenly drop. As a result, the processing process is interrupted, and the cutting head may be damaged.

To avoid such situations, when cutting pre-arranged sheet metal, a non-cutting path is designed between adjacent parts, known as the “empty stroke.”

To prevent equipment damage caused by the nozzle descending during the empty stroke, it is essential to ensure that the empty stroke path avoids the hollow areas on the sheet metal.

In summary, the process elements of laser cutting encompass many aspects.

Through long-term practical experience, we have fully considered the actual processing conditions of laser-cut sheet metal.

We ensure that the processed parts maintain high cutting precision. We also strive to maximize part quality, reduce scrap rates, and lower processing costs.

This requires a comprehensive consideration of the various characteristics of laser cutting processes and the selection of the optimal laser cutting process method.

Conclusion

In actual production, you should consider the material, thickness, and shape of the parts.

You should also take into account the characteristics of various process methods, such as laser cutting hole points and leads, ring-shaped auxiliary cutting paths, laser cutting optimized layout, and common edge cutting.

In addition, you should evaluate interactive laser destruction, laser beam radius compensation, and empty stroke handling.

By combining these considerations, you can optimize the cutting process and achieve the best results..

FAQ

What is laser cutting technology?

Laser cutting is an advanced sheet metal processing method that uses a high-energy-density laser beam, focused through a precision optical system, to melt or vaporize materials. Assisted by gas and controlled by intelligent systems, it delivers high-accuracy, clean cuts for metals and non-metals alike.

How does laser cutting work?

The process starts with a laser source generating a concentrated beam, which is directed and focused into a tiny spot by the focusing system. The intense heat melts or vaporizes the target material, while auxiliary gas blows away molten residue. The control system guides the laser path, producing precise shapes according to design specifications.

What materials can be processed using laser cutting?

Laser cutting can process a wide range of metals—including stainless steel, carbon steel, aluminum alloys, and titanium—as well as non-metal materials such as plastics, glass, ceramics, and composites. Its adaptability makes it suitable for industries from automotive to aerospace, electronics, and mold manufacturing.

What are the main components of a laser cutting system?

A typical laser cutting system includes a laser source (pump source, gain medium, resonant cavity), a focusing system for beam precision, a cooling system to regulate temperature, and an intelligent control system for operational accuracy, fault detection, and automation.

What are the advantages of laser cutting over traditional methods?

Compared to mechanical cutting or plasma cutting, laser cutting offers higher precision (up to ±0.02 mm), cleaner edges without burrs, faster cutting speeds, minimal material waste, and the ability to handle intricate shapes without direct contact, reducing deformation and tool wear.

How accurate is laser cutting?

High-end laser cutting machines can achieve dimensional accuracy within ±0.02 mm and maintain consistent quality across repeated cuts. The narrow kerf width and minimal heat-affected zone help ensure exact part dimensions and smooth surface finishes.

What are the typical applications of laser cutting in manufacturing?

Laser cutting is used for automotive body parts, aerospace components, stainless steel structures, precision holes in watch bearings, prototype fabrication for 3D printing, and intricate mold patterns. It is especially valuable in industries requiring complex shapes and high surface quality.

Can laser cutting handle both metals and non-metals effectively?

Yes. Metals benefit from laser cutting’s precision and speed, while non-metals like plastics and ceramics cut cleanly due to high laser absorption rates and low thermal conductivity, minimizing thermal damage and eliminating the need for extensive post-processing.

Why is laser cutting ideal for mold manufacturing?

In mold manufacturing, laser cutting enables rapid, accurate shaping of complex contours without tool wear or mechanical stress. This reduces scrap rates, extends mold lifespan, shortens production cycles, and helps manufacturers quickly adapt to new product designs.

How is laser cutting technology evolving?

Recent innovations include multi-chuck tube cutting systems for improved stability, intelligent control for automated tail cutting, enhanced cooling systems, and integration with digital manufacturing workflows. These advancements increase cutting precision, efficiency, and material utilization, helping manufacturers stay competitive.