CNC machining uses computers to control tools that make exact parts. This process has changed how factories make products by doing hard tasks automatically and very accurately. It is important in industries like airplanes and cars. It helps save time and money while keeping products high quality.

The worldwide CNC machining market shows how useful it is. In 2019, it was worth $80 billion, and by 2026, it might grow to $115 billion. This growth shows how it helps industries make more products faster and meet today’s needs.

Key Takeaways

- CNC machining uses computers to run tools and make parts fast.

- Industries like aerospace and cars use CNC for better and cheaper production.

- Automation in CNC lowers mistakes, making work safer and easier.

- CNC machines handle many materials like metal and plastic for different uses.

- The future of CNC includes AI and IoT to improve speed and eco-friendliness.

What is CNC Machining?

Definition and Overview

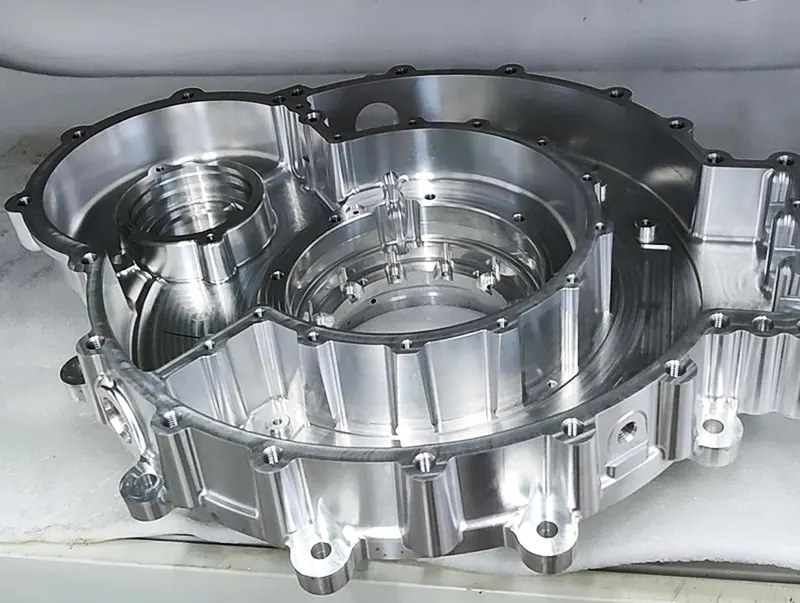

CNC machining is a way to make parts using machines controlled by computers. It cuts material from a solid block, called the stock piece, to form the needed shape. This method works with many materials like metals, plastics, and composites. Industries such as aerospace, telecommunications, and manufacturing depend on CNC machining because it is precise and flexible.

| Component | What It Does |

|---|---|

| CAD Software | Makes designs that turn into G-code for CNC machines. |

| CAM Software | Creates programs to control machines, working with CAD designs. |

| G-code | Commands that tell the CNC machine how to move. |

| M-code | Controls extra actions like turning coolant on or off. |

These tools work together to make sure CNC machining is accurate and reliable.

Key Features of CNC Machining

CNC machining is known for being exact and fast. Factories check for problems early to keep quality high and waste low. In aerospace, it helps make tricky parts faster and cheaper. For medical devices, it creates very detailed parts, helping new ideas grow.

Other important features include:

- Automation: Machines run mostly on their own, reducing mistakes.

- Scalability: They can make a few or many parts easily.

- Versatility: CNC machines work with different materials and designs.

Importance in Modern Manufacturing

CNC machining is very important in today’s factories. It has changed how industries work by making production faster and better. For example, car companies use it to make parts quickly and save money. In aerospace, it ensures parts are made with great care for safety. Automation makes the process even smoother, making CNC machining a key part of modern industry.

CNC machining isn’t just a tool; it’s a big part of how industries grow and improve.

How CNC Machining Works

The Role of Computer Numerical Control

CNC, or Computer Numerical Control, is what powers CNC machining. It uses special software to guide machines and tools. This system follows exact commands called G-code and M-code. G-code tells the machine how to move, while M-code manages extra tasks like turning coolant on. These codes help machines work with little human help.

CNC systems prevent mistakes and keep quality steady. For example, in aerospace, where precision is vital, CNC makes parts that meet strict safety rules. This control makes CNC machining a trusted method in modern factories.

Key Processes in CNC Machining

CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing)

CNC machining starts with CAD software. This tool creates a 3D model of the part you need. After designing, CAM software changes the model into instructions for the machine. These instructions tell the machine how to cut or shape the material.

Programming and Toolpath Generation

Programming is an important step. It creates a toolpath, which is the route the cutting tool follows. This path helps the machine remove material correctly and match the design. Advanced software makes this step easier and improves production.

Machine Operation and Automation

After programming, the CNC machine does the work. Automation lets the machine run without much supervision. Sensors check things like vibration and temperature to keep it running smoothly. Automation saves time and lowers the chance of mistakes.

| Step | Description |

|---|---|

| 5 | Plan the CNC process, focusing on specific tasks. |

| 6 | Create a cutting route and sequence for the machine. |

| 8 | Prepare technical files like flow charts and guides. |

Materials Commonly Used in CNC Machining

CNC machines can use many materials, each for different jobs. Metals like aluminum and steel are strong and long-lasting. Plastics like ABS and PEEK are lightweight and useful for certain parts. Even wood is used, especially in making furniture.

| Material | Properties | Applications |

|---|---|---|

| Nylon | Smooth and reduces friction | Replaces some metal parts |

| ABS | Flexible and easy to shape | Prototypes and molding |

| PMAA | Clear and strong | Replaces glass in optical tools |

| PEEK | Handles high heat well | Aerospace and medical tools |

| Wood | Simple to shape | Furniture making |

Picking the right material helps balance cost and performance.

Types of CNC Machines and Their Applications

CNC Milling Machines

The machines are very useful in making parts. They use spinning tools to cut materials based on CAD designs. These machines are great for making detailed shapes, grooves, and holes. Industries like car-making and factories depend on them for their accuracy and speed.

Vertical CNC milling machines are the most popular, making up 46.3% of the market. They are precise and flexible, perfect for making detailed parts. In car-making alone, they are used 29.7% of the time. These machines are great for producing many parts with exact measurements.

| Type of CNC Machine | Processing Method | Material Capabilities | Applications | Advantages |

|---|---|---|---|---|

| CNC Milling | Moves workpiece with cutting tool | Metals, plastics, wood | Detailed shapes, grooves | Very accurate and fast |

CNC Lathes

CNC lathes are made for turning tasks. The material spins while a tool shapes it. They are best for making round parts like shafts, gears, and threads. These machines are important for industries needing exact curved shapes.

For example, SYIL’s CNC lathe is known for its strong build and advanced tech. It works smoothly and gives steady results, good for small shops or big factories. Haas Automation’s lathes are fast and precise, while DMG Mori’s are durable and modern. These features make CNC lathes reliable and efficient for today’s production needs.

| Type of CNC Machine | Processing Method | Material Capabilities | Applications | Advantages |

|---|---|---|---|---|

| CNC Turning | Spins material with cutting tool | Small, curved materials | Shafts, gears, threads | Better speed and quality |

CNC Routers

CNC routers are flexible machines for cutting softer materials like wood and foam. They are used in industries like cars, planes, and medical tools. These machines are great for making custom designs and detailed parts.

For example, in car-making, CNC routers make foam inserts that cut shipping damage by 95%. In planes, they create lightweight cases for equipment, keeping it safe during transport. In medical fields, they make special packaging for tools, helping with storage and meeting safety rules.

| Type of CNC Machine | Processing Method | Material Capabilities | Applications | Advantages |

|---|---|---|---|---|

| CNC Routers | Cuts and shapes soft materials | Wood, plastics, foam | Custom designs, packaging | Very precise and flexible |

CNC machines come in many types for different jobs. Whether you need accuracy, speed, or flexibility, there’s a CNC machine for you.

CNC Plasma Cutters

CNC plasma cutters are machines that cut metal materials. They work on metals like steel, aluminum, and brass. A hot plasma arc melts the metal, and gas blows it away. This process makes clean and exact cuts. These cutters are great for detailed designs or tough cutting jobs. Industries like construction, car-making, and metalwork use them often.

One big benefit is cutting thick materials easily. They are quicker than older cutting methods and waste less material. For example, in car-making, they make custom parts and frames. In construction, they shape beams and brackets. Their speed and flexibility make them important in modern factories.

Applications Across Industries

Aerospace

In aerospace, accuracy is very important. CNC machines make molds, cases, and covers for airplane parts. They also create robotic arms, sensors, and tools. These parts meet strict safety rules and work well in planes.

Automotive

The car industry uses CNC machines a lot. They make heat sinks, connectors, and parts for electronics. CNC machines also create tools that help build cars faster. Custom parts like gears and shafts are made with CNC too.

Medical Devices

CNC machines are key in making medical tools. They create dental implants, braces, and crowns with great accuracy. These tools fit patients perfectly. CNC technology helps improve medical devices.

Consumer Electronics

CNC machines are used in making electronics. They produce circuit boards, heat sinks, and small parts for gadgets. Devices like phones and laptops need these parts. CNC also makes strong cases and connectors for electronics.

CNC machining helps industries grow and make high-quality products.

Benefits of CNC Machining

Precision and Accuracy

CNC machining is very precise, making exact parts every time. It uses advanced systems to keep quality consistent. Checks happen during and after machining, like visual inspections and measurements. Tools such as Coordinate Measuring Machines (CMMs) ensure parts meet strict rules. For example, the FROGMill™ can be accurate to +/-0.05 mm and repeatable to +/-0.01 mm. This makes it great for detailed designs. Precision is very important in industries like aerospace and medical tools, where even tiny mistakes matter a lot.

Efficiency and Speed

CNC machining is fast and efficient, making parts quickly without losing quality. Cutting speed and feed rate help save time. Faster cutting speeds mean more parts are made, while good feed rates improve efficiency. Systems that monitor machines in real-time reduce downtime and boost productivity. Metrics like Overall Equipment Efficiency (OEE) check machine performance to keep quality high. By lowering errors and increasing output, CNC machining helps meet deadlines and grow production easily.

| Metric | What It Does |

|---|---|

| Cutting Speed | Makes the tool cut faster, saving time. |

| Feed Rate | Controls how fast material moves into the machine, improving work speed. |

| Overall Equipment Efficiency | Checks machine performance, including uptime and quality. |

| Rejection Rate | Tracks bad parts to ensure better production. |

Cost-Effectiveness

CNC machining saves money by using resources wisely and reducing waste. Lean manufacturing helps use materials efficiently, cutting inventory costs. Real-time monitoring reduces downtime, keeping machines running longer and lowering expenses. Faster cutting and feed rates also cut labor costs per part. For example, better efficiency means more parts are made in less time, lowering total costs. This mix of speed, accuracy, and smart resource use makes CNC machining a great choice for businesses wanting to save money.

| Metric | Benefit | How It Saves Money |

|---|---|---|

| Cutting Speed | Makes more parts in less time | Lowers labor costs per part |

| Feed Rate | Speeds up production cycles | Reduces operational costs |

| Real-time Monitoring | Fixes problems quickly, reducing downtime | Increases machine uptime |

| Lean Manufacturing | Uses less material and improves quality | Cuts inventory and material costs |

CNC machining combines accuracy, speed, and savings, making it key for modern factories.

Scalability for Mass Production

CNC machining is perfect for making many parts quickly. Once programmed, the machine makes identical parts over and over. This keeps quality high, even for big projects.

The need for CNC machines is growing fast.

- Factories use them to save money and work faster.

- New CNC machines can handle tough materials like titanium. These materials are key for industries like aerospace, where parts must be very strong.

CNC machines can also change to fit different needs. Whether making a few parts or thousands, they adjust easily. This saves time and keeps production smooth. For example, car companies use CNC machines to make lots of parts without losing quality.

Tip: Want to make more products? CNC machining is a smart and affordable choice.

Reduced Human Error

CNC machining cuts down on mistakes by using automation. Unlike manual work, CNC machines follow exact computer instructions. This ensures every part is made correctly.

Mistakes like wrong measurements or tool slips can ruin parts. CNC machines avoid these problems with advanced software and sensors. For example, real-time checks fix issues during production. This boosts accuracy and saves time and materials.

CNC machines also make workplaces safer. They reduce the need for hands-on work, lowering accident risks. Workers can focus on watching the process instead of doing risky tasks.

CNC machining not only makes parts better—it also creates a safer workplace.

CNC Machining and the Future of Manufacturing

Innovations in CNC Technology

5-Axis CNC Machining

5-axis CNC machines are changing how things are made. Unlike 3-axis machines, they move tools in five directions. This helps create detailed parts with fewer steps. For example, airplane companies use them for turbine blades. These machines save time by cutting many sides at once. They are precise and fast, perfect for industries needing exact parts.

Integration with AI and IoT

AI and IoT are improving CNC machining. AI studies data to improve tool paths and predict repairs. IoT links machines to networks for real-time checks. This makes production faster and reduces waste. For example, smart factories use these tools to avoid extra inventory. Using AI and IoT means quicker work and lower costs.

Trends in Smart Manufacturing

Smart manufacturing is changing factories. Tools like AI, IoT, and data tracking are now important. Many factories use systems to watch production live. The industrial metaverse is also helping with design and testing. These tools make work smoother and products better. Even with challenges, they are a must for modern factories.

Sustainability in CNC Machining

CNC machining is focusing on being eco-friendly. Companies use energy-saving machines and green energy to cut pollution. Some report using 30% less energy with these methods. Others reduce waste by 40% with additive manufacturing. Using recycled metals and biodegradable plastics also helps the planet. These changes save money and protect the environment.

Advancing Industries with CNC Machining

CNC machining is changing industries by making production faster and cheaper. It helps create accurate parts for sectors needing new ideas and efficiency. Here’s how CNC machining improves major industries:

- Aerospace:

Safety and precision are very important in aerospace. CNC machining makes strong, lightweight parts like turbine blades and engine pieces. These parts meet strict safety rules and improve fuel use. CNC also creates complex shapes that were hard to make before. - Automotive:

CNC machining is key in making car parts. It produces engine pieces, transmission systems, and custom car parts with great accuracy. For electric cars, CNC makes battery cases and light frames, helping the industry grow. - Medical Devices:

Medical tools need to be very precise. CNC machining makes implants, surgical tools, and prosthetics that fit perfectly. For example, dental implants made with CNC give patients a comfortable and exact fit. This technology also helps create new medical ideas. - Consumer Electronics:

Many electronics you use daily are made with CNC machines. They create smooth casings for phones, laptops, and tablets. CNC also makes inside parts like heat sinks and connectors, keeping devices working well.

Did You Know? CNC machining can cut production time by half compared to older methods. This speed helps industries meet demand without losing quality.

Application:

| Industry | Key Applications | Benefits of CNC Machining |

|---|---|---|

| Aerospace | Turbine blades, engine parts | Precision, lightweight designs |

| Automotive | Engine components, EV battery housings | High performance, cost savings |

| Medical Devices | Implants, surgical tools | Accuracy, patient-specific designs |

| Consumer Electronics | Smartphone casings, connectors | Reliability, sleek designs |

CNC machining is more than just a tool; it drives progress in industries. By using this technology, companies can create better products faster for everyone.

CNC machining has changed how we make exact parts. It uses smart computers and automation for great accuracy and speed. The process starts with designing in CAD and ends with machines working on their own. It is used in fields like planes, cars, and medical tools. CNC machining saves money and can make many parts quickly. As new technology grows, CNC machining will keep improving. It will help create new ideas and change how industries work.