Injection molding is a way to make parts using molds. Hot, melted material is pushed into a mold to form shapes. This process helps create accurate and good-quality parts quickly. Knowing the main steps is important to keep things consistent.

For instance, tracking things like fill time and pressure helps control the process. This makes sure parts are the same on all machines and shifts. By learning these steps, you can make fewer mistakes and repeat good results easily.

Material Selection in Injection Molding

Common materials used in injection molding

Picking the right material is very important for injection molding. Different materials have special features that suit certain uses. Below are some commonly used materials:

- Thermoplastics: These include polyethylene (PE), polypropylene (PP), and polystyrene (PS). They are popular because they are flexible, strong, and recyclable.

- Engineering Plastics: Examples are polycarbonate (PC) and acrylonitrile butadiene styrene (ABS). They are strong and resist impacts, making them great for car and electronic parts.

- High-Performance Plastics: Polymers like PEEK and ULTEM are very strong and handle heat well. They are often used in airplanes and medical tools.

Each material has properties that affect how it works. For example, tensile strength shows how much stress it can handle. Melt flow rate tells how easily it moves during molding.

| Property | What It Means |

|---|---|

| Tensile Strength | Shows how strong the material is under pressure. |

| Melt Flow Rate | Tells how easily the material flows when heated. |

| Impact Resistance | Measures how well it handles sudden hits or forces. |

| Thermal Properties | Includes how it reacts to heat, like softening or bending temperatures. |

Factors influencing material choice

When choosing a material, think about these things to get the best results:

- Application Requirements: What will the part do? Does it need to handle heat or impacts? For instance, polycarbonate can become brittle in cold temperatures.

- Material Properties: Look at things like impact resistance, flow rate, and heat sensitivity. Materials with lower flow rates are often stronger and resist impacts better.

- Cost and Availability: Match the material’s performance with your budget. High-end plastics like PEEK are great but may cost too much for some projects.

By knowing these factors, you can pick materials that fit your project and make quality parts efficiently.

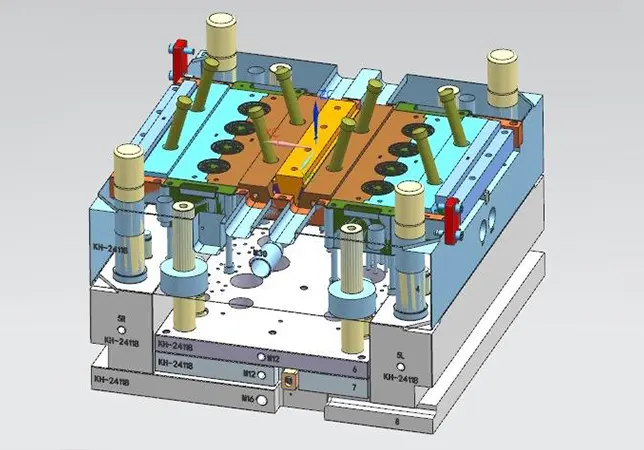

Mold Design and Its Role

Why mold design matters for part quality

Good mold design is very important for making quality parts. It helps the melted material spread evenly, avoiding problems like gaps or weak spots. Using mold flow analysis can find issues early. This lets you fix the design before making parts. Fixing problems early saves time and money.

Keeping the mold at the right temperature is also important. Even temperatures stop stress and make parts better. If the mold is too hot or cold, parts can bend or have dents. Placing gates and cooling lines in the right spots helps too. Gates control how material flows, and cooling lines speed up the process. They also stop uneven shrinking.

By focusing on these details, you can make strong parts with fewer mistakes.

Important steps for mold preparation

Getting the mold ready is as important as designing it. The pressure used must be just right to fill the mold. This step affects how strong the finished part will be. Mold temperature also matters. It changes how the material hardens and affects the part’s look and size.

Testing the process helps find the best settings. For example, using experiments can show what works best. Automatic systems can keep conditions steady, lowering mistakes. Writing down what works during testing helps repeat good results later.

By following these steps, you can make the process better and faster.

Feeding and Melting of Materials

How materials are added to the machine

In injection molding, adding materials is the first step. Plastic pellets or granules are poured into a hopper. The hopper holds the material and feeds it steadily into the machine. Gravity pulls the pellets into the barrel, where a spinning screw moves them forward.

The screw is very important in this process. It pushes the material and squeezes out air bubbles. Air bubbles can make the final product weak. Keeping the feeding steady is key. If the material flow changes, it can cause problems like gaps or rough surfaces.

To keep feeding smooth, watch things like back pressure and speed. Back pressure controls how dense the material is. Injection speed decides how fast the material moves through the system.

| Parameter | Why It Matters |

|---|---|

| Injection Pressure | Fills the mold fully and affects part strength. |

| Back Pressure | Improves the quality of melted plastic. |

| Injection Speed | Affects how well the mold fills and part quality. |

How materials melt in injection molding

When the material reaches the barrel, it starts melting. The screw’s spinning creates heat from friction. Heaters outside the barrel also warm it up. These two heat sources melt the plastic evenly into a liquid form.

Controlling the melt temperature is very important. If it gets too hot, the material can break down and become weak. If it’s not hot enough, the plastic won’t flow well and may not fill the mold. Sensors help check that the temperature stays just right.

Using heat transfer methods helps manage this process. Adjusting the heat settings makes sure the plastic flows smoothly and fills the mold completely. Regular checks, like SPC (Statistical Process Control), can find and fix problems in the melting process.

| Metric | What It Means |

|---|---|

| Cpk | Shows how steady and accurate the process is. A Cpk of 1.33 or higher means good quality. |

By following these steps, you can melt materials evenly and make better parts in your injection molding projects.

The Injection Process Explained

How molten material is injected into the mold

In injection molding, melted material is pushed into a mold. This forms the shape of the part. Before this step, the material is melted and mixed in the barrel. A screw inside the machine moves the melted plastic forward. It forces the material through a nozzle and into the mold.

To get good results, check the melt and mold temperatures. Melt temperature helps the material flow smoothly. Mold temperature affects how the part cools and hardens. Injection pressure is also important. It fills the mold completely and keeps the part strong and accurate.

- Important things to check during injection:

- Injection pressure makes sure the mold is filled fully.

- Mold temperature affects the part’s surface and strength.

- Injection speed controls how well the mold fills.

By managing these steps, you can make parts that are consistent and high-quality.

Role of pressure and speed in the injection process

Pressure and speed are key to controlling the injection process. Pressure helps fill the mold completely. If the pressure is too low, the mold may not fill, leaving gaps. Too much pressure can cause problems like warping or extra material spilling out.

| Effect of Injection Pressure | What Happens |

|---|---|

| Too Low | Gaps or incomplete filling may occur. |

| Just Right | Fills the mold fully and keeps the part accurate. |

| Too High | Can cause warping or extra material spilling out. |

Speed is also very important. If the speed is too slow, the material might harden before filling the mold. This can cause defects. If the speed is too fast, it can create stress in the mold. This stress can lead to bending or surface flaws.

| Effect of Injection Speed | What Happens |

|---|---|

| Too Slow | Material hardens too soon, causing defects. |

| Just Right | Fills the mold properly without issues. |

| Too Fast | Can cause stress, bending, or surface flaws. |

By adjusting pressure and speed carefully, you can make parts that are strong and look great.

Cooling and Solidification

Why the cooling phase is important

The cooling phase is a key step in injection molding. After the melted material fills the mold, it cools and hardens into shape. This step helps the part keep its size and strength. Cooling takes up a big part of the process, often 50% to 70% of the time. Proper cooling stops problems like bending or twisting, which happen if the material doesn’t cool evenly.

But cooling for too long can cause issues too. It makes the process slower and less efficient. To get it right, check cooling times and mold temperatures carefully. Measuring the part’s surface temperature after each cycle helps keep things consistent. Using heat transfer methods ensures even cooling, which is needed for making good-quality parts.

| Aspect | Details |

|---|---|

| Cooling Phase Duration | Takes 50% to 70% of the cycle time, affecting size. |

| Insufficient Cooling Impact | Can cause bending or twisting from uneven hardening. |

| Excessive Cooling Impact | Slows production and lowers efficiency. |

| Management Recommendations | Check cooling times and mold temperature; measure surface temperature each cycle. |

| Scientific Principles | Use heat transfer methods to ensure even cooling and better results. |

How cooling systems improve accuracy

Cooling systems are very important for making accurate parts. They help the melted plastic harden evenly inside the mold. Even cooling stops problems like bending, rough surfaces, or leftover stress. This makes the final parts strong and the right size.

Good cooling systems use channels to remove heat evenly from the mold. These channels stop hot spots that can cause uneven shrinking. Using the right cooling liquids, like water or oil, and controlling their flow speeds improves heat removal.

- Benefits of good cooling systems:

- Reduce bending and improve part quality.

- Remove heat evenly with well-designed channels.

- Boost efficiency by controlling cooling liquids and flow speeds.

By using these methods, you can make parts more accurate, shorten cycle times, and improve the injection molding process.

Ejection and Post-Processing

How parts are ejected from the mold

After cooling, the molded part needs to be removed. This step is called ejection and keeps the part’s shape and quality. Pins, plates, or air push the part out of the mold. The force must be just right. Too much force can break the part. Too little force can leave it stuck.

To eject parts smoothly, think about the part’s shape, material, and mold surface. For example:

- Smooth mold surfaces make it easier to remove parts.

- Materials that shrink a lot need extra care during ejection.

- Timing is important to let the part cool enough to keep its shape.

Modern systems, like closed-loop controls, adjust force and timing automatically. These systems help keep ejection steady and reliable.

Tip: Try Design of Experiments (DOE) to find the best ejection settings for your project.

Common finishing steps in injection molding

After ejection, parts often need finishing to look and work better. Finishing makes parts stronger, smoother, and ready to use. Common finishing steps include:

- Trimming: Cuts off extra material from the edges.

- Surface Treatment: Improves how the part looks or feels, like polishing or painting.

- Assembly: Joins molded parts together to make a complete product.

- Inspection: Checks if the part meets size and quality standards.

To make sure parts are high-quality, follow these steps:

| Finishing Step/Metric | Description |

|---|---|

| Temperature Management | Keeps melt and mold temperatures at the right levels. |

| Pressure Control | Ensures enough pressure to fill the mold properly. |

| Cooling Processes | Helps the part harden and keeps its size correct. |

| Validation Procedures | Checks molds to confirm they make good-quality parts. |

Quick Mold Change (QMC) systems save time by switching molds faster. They cut mold change times from hours to minutes. Using Statistical Process Control (SPC) helps track production and fix problems quickly.

Note: Always check melt temperature, mold temperature, and cooling times for consistent results.

Knowing the parts of injection molding is very important. Each step, from picking materials to finishing, helps make good parts. Understanding these steps reduces mistakes and makes production better.

Using this knowledge can improve how you work and get steady results. Whether you are designing molds or handling cooling, paying attention to details helps. This will let you create strong and precise parts. Use these tips to make your injection molding projects better today.

FAQ

What is injection molding and how does it work?

Injection molding is a manufacturing process where melted plastic is injected into a mold to form precise and high-quality parts. It involves steps such as material selection, mold design, feeding and melting, injection, cooling, ejection, and finishing.

Why is material selection important in injection molding?

Choosing the right material ensures the part meets performance requirements like strength, heat resistance, and impact durability. Factors such as application needs, cost, and material properties like melt flow rate and tensile strength influence the choice.

What are the most common materials used in injection molding?

Popular options include thermoplastics (PE, PP, PS) for flexibility and recyclability, engineering plastics (PC, ABS) for impact resistance, and high-performance plastics (PEEK, ULTEM) for heat and strength-critical applications.

How does mold design affect injection molding quality?

A well-designed mold ensures even material flow, prevents defects like warping or voids, and reduces production waste. Key design factors include gate placement, cooling channels, and maintaining consistent mold temperatures.

What role do temperature and pressure play in injection molding?

Melt temperature determines plastic flow, while mold temperature influences cooling and part stability. Injection pressure ensures complete mold filling, and precise control of both avoids defects like short shots or warping.

Why is the cooling phase crucial in injection molding?

Cooling makes up 50–70% of the production cycle and directly affects part accuracy, strength, and dimensional stability. Proper cooling prevents warping, reduces cycle time, and ensures consistent quality.

How can cooling systems improve part accuracy in injection molding?

Efficient cooling systems use strategically placed channels and controlled liquid flow to remove heat evenly, preventing defects like uneven shrinkage, bending, and surface flaws.

What happens during the ejection phase of injection molding?

Ejection removes the cooled part from the mold using pins, plates, or air. Proper timing and force prevent damage, while mold surface smoothness and material shrinkage are considered to ensure clean removal.

What are common post-processing steps after injection molding?

These include trimming excess material, surface treatments like polishing or painting, assembly of multiple components, and quality inspection to ensure parts meet specifications.

How can injection molding consistency be improved across production runs?

Tracking key parameters like fill time, pressure, melt temperature, and cooling duration ensures repeatability. Using SPC (Statistical Process Control) and mold flow analysis also helps maintain consistent results.