Technicians should simultaneously establish a robust feedback mechanism to promptly relay inspection results to machinists and technical personnel.

Table of Contents

Precision honing process plays a crucial role in enhancing the performance and reliability of diesel engines in today’s rapidly advancing industrial landscape.

As a core machining technique, it directly influences the surface quality of cylinder liners, which are essential for fuel efficiency, durability, and operational stability.

The cylinder liner’s surface condition significantly affects the overall performance of diesel engines, making effective control of its surface roughness a critical priority in modern manufacturing.

This study focuses on the precision honing process for diesel engine cylinder liners, analyzing its surface roughness control methods in depth.

By refining process parameters and optimizing machining strategies, the research demonstrates notable improvements in liner surface quality, offering strong technical support for boosting engine performance and ensuring long-term operational stability.

Overview of Precision Honing Process and Surface Roughness Control

The precision honing process for diesel engine cylinder liners is a critical manufacturing technology.

Through a meticulous machining process, it achieves strict control over the surface roughness of cylinder liners, thereby enhancing their wear resistance, sealing performance, and lubrication capabilities.

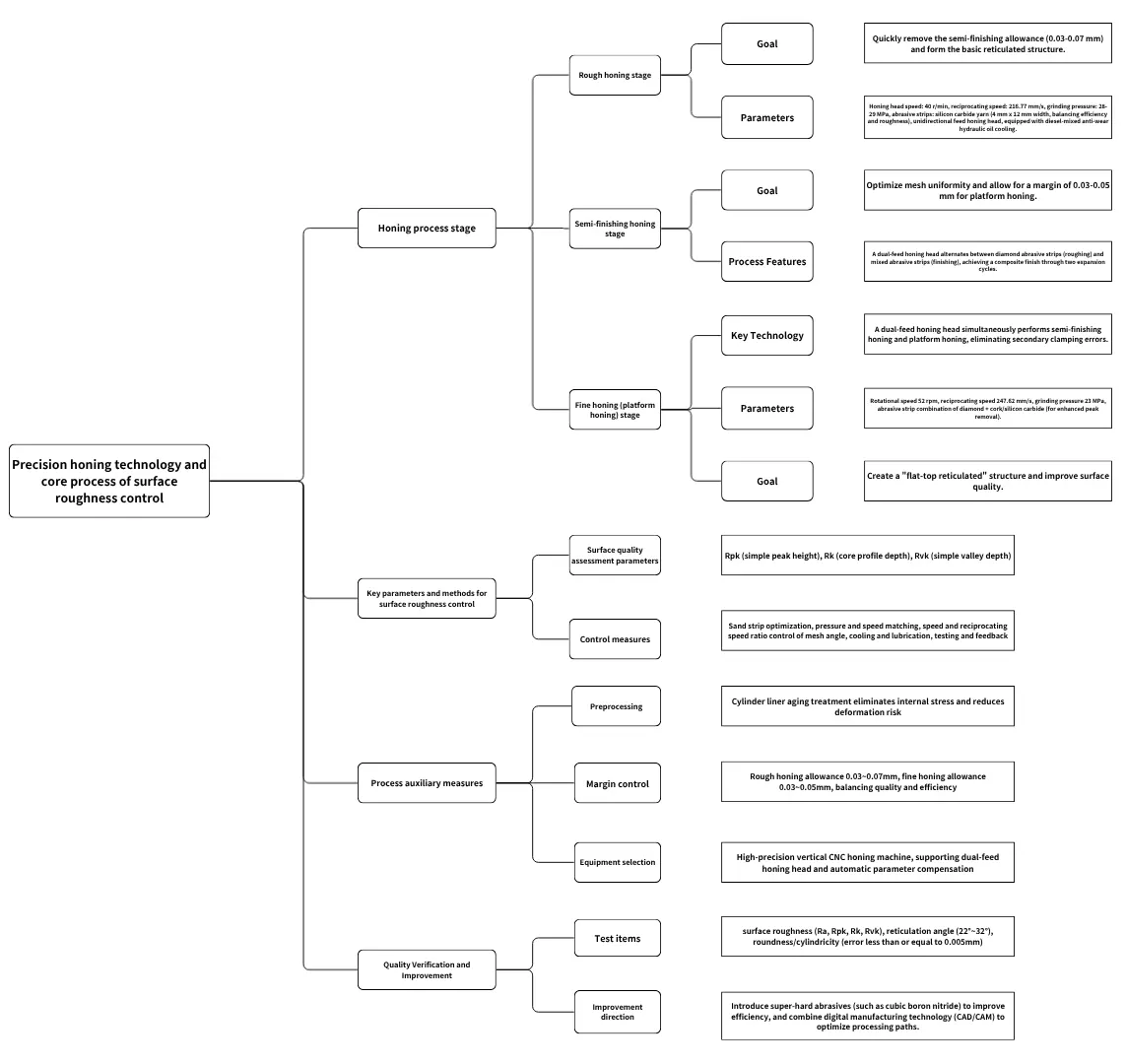

The core process flow for precision honing and surface roughness control of diesel engine cylinder liners is illustrated in Figure 1.

Stages of Precision Honing Process

The precision honing process for diesel engine cylinder liners involves multiple sequential stages, each designed to achieve specific machining objectives.

By carefully managing these stages—rough honing, finish honing, and final polishing—manufacturers can ensure optimal

of the cylinder liner.

- Rough Honing Stage

As the initial critical step in the precision honing process for diesel engine cylinder liners, the rough honing stage primarily aims to rapidly remove the majority of surface stock from the cylinder liner, thereby creating favorable conditions for subsequent machining.

During rough honing, selecting appropriate abrasive strips is essential. Typically, wide silicon carbide strips (e.g., 4 mm × 12 mm) are widely used due to their excellent wear resistance and cutting performance.

These strips ensure stable machining by effectively controlling vibration while maintaining processing efficiency.

Secondly, optimizing machining parameters is critical.

During rough honing, employing higher pressure (typically between 28–29 MPa) enhances material removal rates, thereby reducing processing time.

Simultaneously, adjusting spindle speed and reciprocating speed ensures full contact between the abrasive strip and cylinder liner surface, achieving uniform cutting.

During machining, the usage of cutting fluid must be closely monitored.

Cutting fluid not only provides cooling and lubrication but also effectively removes chips, preventing abrasive strip clogging.

Therefore, maintaining appropriate cutting fluid pressure and flow rate is essential to create an optimal machining environment.

After rough honing, a preliminary inspection of the cylinder liner surface is required to confirm the removal of excess material, preparing for the next machining stage.

Semi-Finishing Honing Process Stage

Serving as the transitional phase between rough and finish honing, the semi-finishing honing process primarily aims to further reduce the machining allowance on the cylinder liner surface, bringing surface quality closer to final design specifications.

During semi-finishing honing, abrasive strip selection is critical.

Sand strips similar to those used in rough honing may be employed, but their wear condition must be closely monitored for timely replacement to ensure machining quality.

Machining parameters require finer adjustment. Compared to rough honing, semi-finish honing employs lower pressure (typically around 80% of rough honing pressure). This effectively reduces surface cutting forces and prevents excessive machining stresses.

Simultaneously, controlling the contact state between the abrasive strip and cylinder liner surface by adjusting spindle speed and reciprocating speed ratio ensures stable cutting.

During processing, enhanced monitoring and management of cutting fluid are essential. Ensure the fluid remains clean and free of contaminants, and adjust its pressure and flow rate as needed to maintain a stable machining environment.

Furthermore, after semi-finishing honing, conduct a comprehensive inspection of the cylinder liner surface to verify that the removal of stock and surface quality meet the requirements for the next processing stage.

Finishing Honing Process Stage

As the final stage of the precision honing process for diesel engine cylinder liners, the finishing honing process primarily aims to perform fine machining on the cylinder liner surface to achieve the predetermined surface roughness and topography requirements.

During fine honing, abrasive strips must be selected appropriately. Diamond-cork composite strips are typically used due to their excellent cutting performance and self-sharpening properties, effectively removing microscopic surface protrusions and burrs to enhance surface quality.

Process parameters must be set with extreme precision. The fine honing stage employs lower pressure (generally around 23 MPa) to protect the cylinder liner surface from damage.

Simultaneously, precise control of spindle speed and reciprocating speed ratio creates an ideal grid angle and surface topography.

During machining, rigorous monitoring and management of the cutting fluid are essential. The fluid must remain clean and free of impurities, with its pressure and flow rate adjusted as needed to maintain a stable machining environment.

Furthermore, close attention must be paid to abrasive strip wear, with timely replacement to ensure consistent machining quality.

Following precision honing, the cylinder liner surface must undergo comprehensive inspection.

Precision measurement equipment such as multi-angle profilometers is typically employed to accurately measure and analyze surface roughness, grid angle, and topography, ensuring the cylinder liner surface quality meets design specifications.

Key Parameters and Methods for Surface Roughness Control

Achieving the desired surface finish in the precision honing process of diesel engine cylinder liners requires a clear understanding of surface quality metrics and practical control measures.

Effective parameter selection and consistent monitoring are essential to improve performance, durability, and lubrication properties of the cylinder liner.

Setting Surface Quality Evaluation Parameters

In the precision honing process of diesel engine cylinder liners, surface quality assessment is a critical step to ensure final product performance.

To precisely control the surface roughness of cylinder liners, a comprehensive evaluation using three parameters—Rpk, Rk, and Rvk—is employed.

The Rpk parameter controls initial wear on the liner surface, with its value strictly maintained below 0.5 μm.

This parameter is set to minimize surface micro-asperities, reduce initial wear rates, and thereby extend the liner’s service life.

The Rk parameter determines the lubrication contact performance of the liner surface, with its ideal range set between 1.2 and 2.7 μm.

Optimizing the Rk value ensures the formation of an effective lubricating film between the cylinder liner and piston rings, reducing friction losses and enhancing engine efficiency.

The Rvk parameter relates to the oil-holding capacity of the cylinder liner surface, with its value set between 3.0 and 5.8 μm.

An appropriate Rvk value ensures sufficient oil-holding space on the cylinder liner surface, providing continuous lubrication for the piston rings while minimizing oil consumption.

In practice, multi-point measurements of the cylinder liner surface are conducted using high-precision instruments to obtain specific Rpk, Rk, and Rvk values. These values are then evaluated and adjusted according to the aforementioned standards to ensure the cylinder liner surface quality meets design requirements.

Surface Roughness Control Measures

The selection and optimization of abrasive strips are critical for controlling cylinder liner surface roughness.

During rough honing, wide silicon carbide honing strips (4 mm × 12 mm) are employed. These strips offer excellent wear resistance and cutting performance, effectively controlling vibration while ensuring machining efficiency and process stability.

For finish honing, diamond-cork composite honing strips are used.

Diamond strips possess extremely high hardness and wear resistance, effectively removing surface micro-protrusions and burrs;

while the cork acts as a buffer, reducing the risk of scratches on the cylinder liner surface.

Precise control over the abrasive strip’s grit size, hardness, and shape enables fine adjustment of the cylinder liner’s surface roughness.

> Pressure and Speed Control in Honing Process

During machining, the balance between pressure and speed significantly impacts surface roughness.

During rough honing, higher pressure (28–29 MPa) combined with appropriate spindle speed and reciprocating speed ratios can enhance material removal rates and reduce processing time.

Simultaneously, adjusting pressure parameters controls cutting depth to prevent overcutting or undercutting.

For finish honing, lower pressure (23 MPa) and more precise spindle speed and reciprocating speed ratio control are employed.

Reducing pressure minimizes damage to the cylinder liner surface while ensuring full contact between the honing strips and the workpiece surface, thereby achieving stable cutting.

Furthermore, precise control of the rotational speed and reciprocating speed ratio creates an ideal mesh angle, enhancing the oil retention capacity and lubrication performance of the cylinder liner surface.

> Cooling, Lubrication, and Chip Removal Optimization

Optimizing the cooling and lubrication system is equally critical for controlling surface roughness.

During machining, cutting fluid primarily serves cooling and lubrication functions while effectively removing chips to prevent abrasive clogging.

Therefore, maintaining appropriate cutting fluid pressure and flow rate is essential to sustain optimal machining conditions.

This study primarily employs diesel-blended anti-wear hydraulic oil as cutting fluid, which offers excellent cooling and lubrication properties to effectively reduce friction heat and wear during processing.

Simultaneously, adjusting the pressure and flow parameters of the cutting fluid can further optimize chip removal and cooling efficiency, ensuring consistent improvement in cylinder liner surface quality.

> Real-Time Surface Quality Inspection and Feedback

To guarantee that the cylinder liner surface quality meets design specifications, we must employ high-precision inspection equipment for real-time monitoring and feedback.

Comprehensive surface inspection using a multi-angle profilometer captures critical parameters such as surface roughness, grid angle, and topography.

By comparing inspection data against preset standards, we can promptly identify issues during machining and make corresponding adjustments.

During inspection, we must ensure the accuracy and stability of testing equipment to avoid human-induced errors.

This allows them to adjust machining parameters and process plans based on feedback, ensuring continuous improvement and enhancement of cylinder liner surface quality.

Auxiliary measures for processing technology

In the precision honing process of diesel engine cylinder liners, supporting measures are crucial for ensuring machining quality and efficiency.

During the pre-treatment phase, the core task involves stress relieving the liners to eliminate internal stresses, thereby reducing the risk of deformation during subsequent machining.

Technicians typically perform stress relieving before liner machining by placing the liners in a constant-temperature environment for a specified duration to release internal material stresses.

Technicians must strictly control temperature and duration parameters, keeping temperatures below the material’s recrystallization point and adjusting the duration based on the liner’s material and dimensions.

This treatment significantly enhances dimensional stability and machining accuracy, laying a solid foundation for subsequent honing operations.

Allowance control is a critical aspect of precision honing, directly impacting both quality and efficiency.

During rough honing, technicians set the allowable range at 0.03–0.07 mm to rapidly remove bulk material and establish a strong foundation for subsequent operations.

For finish honing, technicians control allowances between 0.03–0.05 mm to ensure the surface quality meets design specifications.

Operators use high-precision measuring equipment to monitor cylinder liner dimensions in real time during processing. They then adjust processing parameters based on the measurement results to achieve precise allowance control.

Furthermore, equipment selection is critical for the successful implementation of precision honing processes.

We recommend using high-precision vertical CNC honing machines because they support dual-feed honing heads and automatic parameter compensation, which significantly enhance machining accuracy and efficiency.

During selection, engineers must comprehensively evaluate factors such as machining capacity, precision stability, automation level, and maintenance convenience.

Simultaneously, engineers should configure auxiliary devices like abrasive strips, cutting fluid supply systems, and inspection equipment according to specific machining requirements to ensure coordinated operation of the entire processing system.

Processing technology and its quality verification and improvement

To ensure the machining quality of the precision honing process for diesel engine cylinder liners, engineers must conduct rigorous quality verification on the processed liners and propose improvement directions based on the verification results.

Key inspection items include surface roughness (Ra, Rpk, Rk, Rvk), pattern angle (22°–32°), and roundness/cylindricity (error ≤ 0.005 mm).

Surface roughness serves as a critical indicator of liner surface quality, measured using high-precision instruments such as multi-angle profilometers.

The groove angle directly impacts the cylinder liner’s lubrication performance and oil retention capacity, requiring precise measurement via microscopes or specialized equipment;

Roundness and cylindricity reflect the liner’s dimensional accuracy, which is critical for ensuring normal engine operation.

Based on quality verification results, engineers can propose the following improvement directions:

Introduce super-hard abrasives (e.g., cubic boron nitride) to enhance machining efficiency.

These super-hard abrasives possess higher hardness and wear resistance, effectively reducing machining time while improving surface quality.

Optimize machining paths by integrating digital manufacturing technologies (CAD/CAM).

Engineers can precisely plan machining paths and parameter settings through digital modeling and simulation analysis, further enhancing machining accuracy and efficiency.

Additionally, engineers must regularly maintain and calibrate machining equipment and inspection instruments to ensure they remain in optimal working condition..

Conclusion

This paper systematically elucidates the entire precision honing process for diesel engine cylinder liners through in-depth research on the technique and its surface roughness control methods.

It covers three stages—rough honing, semi-finish honing, and finish honing—and thoroughly analyzes key parameters and approaches for surface roughness control.

By implementing refined control strategies—such as optimizing abrasive strips, matching pressure and speed, and enhancing the cooling lubrication system—engineers have effectively reduced the surface roughness of cylinder liners..

This significantly improves wear resistance and sealing performance, thereby enhancing the overall performance and operational stability of diesel engines.

This research provides a scientific basis for diesel engine cylinder liner processing and offers robust support for technological advancement in related fields.

With the continuous advancement of materials science and machining technology, engineers will further refine the precision honing process for diesel engine cylinder liners, enhancing machining efficiency and quality.

Integrating digital manufacturing technologies such as CAD/CAM holds great promise for optimizing machining paths and improving machining accuracy.

This advancement injects new vitality into ongoing innovation and development within the diesel engine manufacturing sector.

FAQ

What is the precision honing process for diesel engine cylinder liners?

The precision honing process is a high-accuracy machining method used to refine the surface roughness of diesel engine cylinder liners. It enhances liner wear resistance, lubrication performance, and sealing capability, directly boosting engine efficiency, durability, and operational stability.

Why is controlling surface roughness important in diesel engine cylinder liners?

The surface roughness of cylinder liners significantly impacts fuel efficiency, oil retention, sealing performance, and piston ring wear. Proper roughness control minimizes friction losses, reduces oil consumption, and extends the overall lifespan of the diesel engine.

What are the main stages of the precision honing process?

The process includes three core stages:

Rough Honing: Rapidly removes the bulk of material to shape the liner.

Semi-Finish Honing: Refines the surface closer to final specifications.

Finish Honing: Achieves the desired surface roughness, crosshatch angle, and oil-retention properties for optimal engine performance.

How do abrasive strips affect the precision honing process?

Abrasive strip selection and optimization are crucial for achieving consistent surface quality.

Silicon carbide strips are typically used for rough honing due to their strong cutting ability.

Diamond–cork composite strips are used in finish honing for superior precision, reducing microscopic surface irregularities without scratching the liner.

What are the key parameters for evaluating cylinder liner surface quality?

Surface quality is assessed using three primary parameters:

Rpk: Controls initial wear (kept below 0.5 μm).

Rk: Influences lubrication contact performance (1.2–2.7 μm range).

Rvk: Determines oil-holding capacity (3.0–5.8 μm range).

Monitoring and adjusting these metrics ensures that cylinder liners meet stringent design standards.

How do pressure and speed influence the honing process?

The balance of honing pressure and spindle/reciprocating speed directly affects cutting depth, material removal, and final surface roughness:

Rough honing: Higher pressure (28–29 MPa) speeds up material removal.

Finish honing: Lower pressure (about 23 MPa) prevents surface damage and achieves a consistent crosshatch pattern for enhanced lubrication.

What role does cutting fluid play in precision honing?

Cutting fluid is essential for cooling, lubricating, and chip removal during honing. Proper fluid pressure and flow prevent abrasive clogging, reduce frictional heat, and maintain a stable machining environment, ultimately improving surface quality and extending tool life.

How is surface quality inspected during and after honing?

High-precision instruments such as multi-angle profilometers are used for real-time monitoring of surface roughness, crosshatch (mesh) angle, and topography. Continuous feedback from these inspections allows engineers to adjust process parameters promptly, ensuring consistent quality across all liners.

What technologies enhance the precision honing process?

Digital manufacturing tools like CAD/CAM help simulate and optimize machining paths, improving both accuracy and efficiency. Additionally, super-hard abrasives (e.g., cubic boron nitride) further enhance wear resistance, shorten machining time, and improve the surface finish of cylinder liners.

How does the precision honing process improve diesel engine performance?

By achieving superior surface smoothness, crosshatch angles, and oil retention, the precision honing process enhances lubrication, reduces frictional wear, and prevents oil leakage. This leads to better fuel efficiency, lower maintenance costs, longer engine life, and stable long-term performance.