In manufacturing, while producing complex parts is challenging, precise quality control is even more intricate and often difficult to manage. Those who excel in this area will gain recognition from the market and customers.

Many renowned companies, such as General Motors and Toyota, have actively accumulated extensive experience and knowledge in the automotive manufacturing sector through long-term dedication.

Case Study: Crankshaft Machining

Take the crankshaft component in automobiles as an example. The transmission system amplifies dimensional deviations between the connecting rod journals and main journals.

This amplification leads to a chain reaction of quality issues, such as abnormal bearing wear and increased cylinder block vibration.

This underscores the critical importance of crankshaft machining precision control in engine manufacturing.

However, crankshafts possess unique structural characteristics—multiple crankpins and slender shafts—requiring over twenty machining processes including turning, drilling, and grinding.

Quality control factors across these stages exhibit significant interactive influences.

Particularly during center hole machining at the flange end, cumulative factors frequently cause center hole positional deviations.

These factors include cutting force variations from tool wear, clamping misalignment due to residual chips on fixture surfaces, and reduced spindle rigidity.

Such defects are difficult to fully detect during initial inspections but can trigger imbalance failures during high-speed engine operation, potentially leading to severe consequences like crankshaft fracture.

The team implemented a comprehensive improvement plan to resolve machining quality issues in flange-end center holes for a specific crankshaft model.

The plan incorporated equipment condition monitoring, process parameter optimization, and inspection system upgrades.

By analyzing the dynamic characteristics of the machine-tool-cutting tool-fixture system and optimizing cutting parameter matching rules, we improved process stability.

In addition, the design of an automatic chip removal device ensured effective control of machining accuracy.

This study provides a reference engineering case for process coordination optimization of complex structural components, holding positive significance for enhancing the manufacturing reliability of critical automotive parts.

Production Case

This study selected a crankshaft from an automotive enterprise’s engine as a case study, where the first-pass yield rate for a specific crankshaft model failed to meet quality control targets.

According to the enterprise’s Business Plan Deployment (BPD) requirements, the First Time Quality (FTQ) for this crankshaft model must be ≥99.3%. However, actual monitoring data showed a yield rate of only 99.1% (Figure 1).

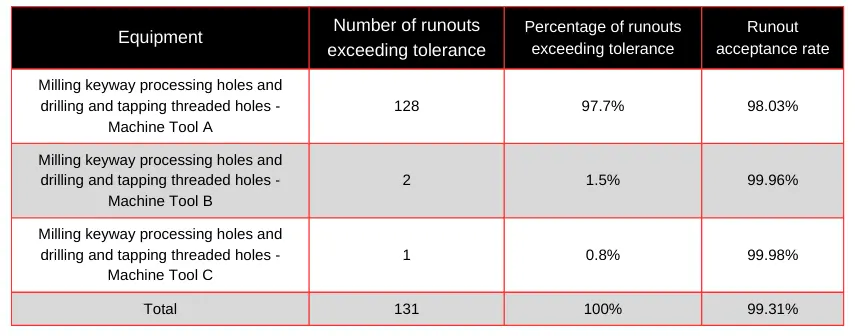

Further analysis showed that the machining processes produced defects concentrated in flange-end center holes with runout exceeding tolerances.

Among these, 97.7% of nonconforming parts originated from the machining center’s keyway milling process hole and threaded hole drilling/tapping process-A.

The actual FTQ for this process was 99.31%, while the FTQ for the problematic keyway milling process hole and threaded hole drilling/tapping process-A machine tool was only 98.03%.

Although the overall pass rate (99.1%) approached the BPD requirement, insufficient capability in this critical process still constrained quality breakthroughs.

Therefore, this research focused on raising the FTQ of the keyway milling process hole and thread drilling/tapping hole-A to 99.96%, ensuring the overall pass rate exceeded the BPD requirement of 99.3%.

Figure 1 Production Pass Rate

Analysis of Failure Contributing Factors

To understand why the overall first-pass yield rate failed to meet the BPD requirements, it is necessary to systematically analyze the factors contributing to crankshaft defects.

The study focused on the machining processes that directly influence flange-end center hole accuracy, because deviations in this area propagate downstream and affect overall engine performance.

The team considered several potential contributors, including equipment condition, tool wear, clamping alignment, and cumulative errors from preceding processes.

By identifying the processes that most impacted nonconforming parts, they developed targeted improvements to enhance the first-time quality of the crankshaft production line.

This analysis provides the basis for a detailed examination of process-specific failures, beginning with the keyway milling and thread drilling/tapping process-A, which preliminary data suggested as the primary source of defects.final quality, as detailed in Table 1.

-

Failure Analysis

By tracing 131 nonconforming parts produced in April of a certain year, it was found that 97.7% (128 parts) of defective items were concentrated in the machining center’s keyway milling process holes and drilling/tapping threaded holes-A process.

Only 2.3% (3 parts) were attributable to residual semi-finishing errors from the preceding roller grooving and straightening processes.

The company’s published overall crankshaft production line pass rate of 99.1% represents final inspection data, while the 99.31% pass rate for the keyway milling and thread drilling/tapping process A is the average across three machines.

The single-machine pass rate for the problematic equipment was only 98.03% .

To further validate the impact of each process, reverse machining experiments were conducted:

Using standard samples with preceding process errors ≤0.005 mm, the finished product pass rate reached 99.95% after the keyway milling process hole and thread drilling/tapping process-A.

After introducing a 0.020 mm error in the groove rolling and straightening process, compensatory machining in the keyway milling process hole and thread drilling/tapping process A still maintained a pass rate of 99.3%.

Experimental results indicate that the equipment condition during the keyway milling process hole and thread drilling/tapping process-A plays a decisive role in final quality, as detailed in Table 1.

-

Root Cause Analysis

The technician conducted a systematic investigation across six dimensions: personnel, machinery, materials, methods, environment, and measurement.

Other engineer measured the radial runout of the spindle during the keyway milling and thread drilling/tapping process (Process A) at 0.018 mm, which exceeded the process standard of ≤0.012 mm in the equipment dimension.

This directly caused tool path deviation. Simultaneously, residual metal chips on the fixture’s locating surfaces caused clamping inaccuracies occurring 4 times daily, further amplifying machining errors.

In the material dimension, the process capability index (CPK) for hole diameters from preceding operations was 1.67, meeting the ≥1.33 qualification requirement.

However, its dispersed distribution still contributed 12.7% of quality variation.

In the process method dimension, improper feed rate parameter settings caused cutting force fluctuations. Orthogonal test results showed a highly significant impact on runout values (P=0.032).

In the operator dimension, video monitoring verified 100% fixture cleaning compliance per shift.

In the environmental dimension, ±2°C temperature/humidity fluctuations in the workshop were confirmed to have no significant impact via constant-temperature comparison experiments.

Calibration of the coordinate measuring machine showed an error below 0.002 mm, complying with metrology standards for the inspection dimension.

Analysis of variance (ANOVA) quantified the factor contributions.

Cumulative factors related to the milling keyway process holes and drilling/tapping thread holes on Machine A accounted for 82.3% of the issue. Spindle runout contributed 62.1%, and fixture cleanliness contributed 20.2%, identifying them as the core factors.

Problem-Solving Measures

Based on the analysis of contributing factors, it was clear that the majority of defects originated from the milling keyway process holes and drilling/tapping thread holes on Machine A, with spindle runout and fixture cleanliness identified as the core issues.

To systematically address these problems, a series of targeted interventions were designed.

These measures focused on equipment maintenance, process parameter optimization, and verification of metrology and fixture conditions to improve the first-pass yield rate.

The corrective actions were prioritized according to their expected impact on FTQ, starting with the most critical factor: the condition of the machine tool probes and their feedback systems.

Implementing these measures aimed to stabilize machining accuracy, reduce dimensional deviations, and ensure that subsequent process improvements would be effective.

-

Replace Probe and Feedback Cable

The probe on the milling keyway process hole and drilling/tapping thread hole-A machine tool was damaged.

The damaged feedback cable of this machine tool’s probe affected the pass rate, necessitating replacement of both the probe and its feedback cable.

After replacement, measure the probe’s spring force and stability, tracking data continuously for one production shift.

The inspection standard is a rebound pressure of 120-220 N. After 9 consecutive tests, the force values were 158, 189, 201, 198, 183, 163, 199, and 185, all meeting the standard.

Simultaneously, the new left probe on the milling keyway process hole and drilling/tapping thread hole-A machine tool was tested five times, yielding values of 49.003, 49.001, 48.998, 48.997, and 49.001.

The right probe was also tested five times, yielding values of 49.003, 49.003, 48.997, 48.999, and 49.001. Therefore, both probe springback pressure and probe stability fall within acceptable ranges.

One week later, tracking statistics for the FTQ data of a specific crankshaft model showed it reached 99.8%, achieving the improvement objective.

-

Optimizing Rotational Speed and Adding Fixture Flushing Functionality

Analysis of the previous non-compliance in pass rate primarily attributed to excessively rapid feed per revolution and accumulated iron chips in the fixture, necessitating improvements.

Countermeasures included optimizing rotational speed and feed rate, along with adding fixture flushing functionality to remove iron chips.

The rotational speed was increased from 900 r/min to 1,000 r/min, and the feed rate was adjusted from 190 mm/min to 200 mm/min.

Additionally, piping and programming were modified to enable automatic flushing of the fixture positioning points.

These improvements reduced the length of machining chips from 95.000 mm to 30.000 mm, with a reduction rate exceeding 90%.

Simultaneously, the frequency of chip accumulation at fixture positioning points decreased to 0 times per day.

A 6-day follow-up confirmed chip length reduction from 95,000 mm to 30,000 mm, achieving 96% compliance—demonstrating significant effectiveness.

-

Removal of Machining Allowance for Crankshaft Processing

The blank undergoes allowance removal according to design specifications.

Due to previous production inconsistencies, many blanks exhibited surface irregularities and were unusable as-is.

The target area for removal is the machining allowance.

Engineers used a reference table method, consulting historical production data tables to adjust and determine the crankshaft machining allowance.

The raw material for this crankshaft component is 45 steel with a hardness of 250 HBS.

The designed blank weight is 48 kg, produced via die forging. After consulting historical tables, the forging weight was confirmed as 48 kg.

Except for the crankpin and end face holes, all other surfaces of the crankshaft are machined using grinding processes, with calculations performed according to the following formula:

In this equation, S denotes the complexity of the crankshaft forging’s geometry, represented by a real number.

M1 refers to the quantity of forgings, expressed in kilograms (kg).

M2 denotes the weight of the forging’s outer contour envelope, expressed in kg. To calculate this, use the following formula:

where R represents the maximum diameter of the forging, measured in mm. L denotes the unit mass of the forging, expressed in kg/mm.

If the forging has a maximum diameter of 200.000 mm and a length of 605.000 mm, substituting these values into the formula yields S (shape complexity) as 0.326.

Refer to prior data to determine the forging’s weight, external dimensions, and grinding precision.

For diameter machining, the single-side machining allowance must be controlled between 2.600–3.100 mm.

For horizontal machining, the single-side allowance must be maintained between 2.800–3.400 mm.

The surface roughness of workpieces requiring machining allowances must exceed 1.6 μm.

If surface roughness is below 1.6 μm, additional machining allowance must be added.

-

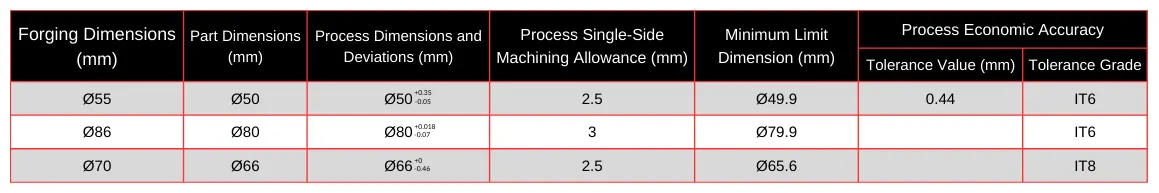

Selection of Process Dimensions and Tolerances

During crankshaft machining, it is crucial to analyze the dimensional data specified in the design drawings, such as the process dimensions for mechanical machining.

Simultaneously, process dimensions must be calculated based on actual conditions to ensure machining quality.

Strict adherence to the Concise Handbook of Mechanical Manufacturing Process Design is required.

Process dimensions, tolerances, and other parameters must be set according to its data to guarantee machining accuracy meets specified requirements.

Table 1 presents key process dimension and tolerance calculation data.

Specifically, the axial runout error and residual flash of the crankshaft blank must not exceed 1.200 mm.

For a crankshaft forging weighing 48 kg, assuming a shape complexity of S2 and material carbon content of 0.45%.

After consulting reference materials, we classified the forging’s material shape complexity as M1.

To achieve the specified precision, production must follow the component requirements outlined in the Concise Handbook of Mechanical Manufacturing Process Design.

The machining dimensions and tolerances for the connecting rod journal are established as follows:

(1) Forging process dimensions and tolerances: φ70.000 +1

-1 mm, tolerance value 2.000 mm.

(2) Rough turning process dimensions and tolerances: φ68.000 +0.25

0 mm, single-side process allowance 3.000 mm, tolerance value 0.250 mm;

(3) The grinding process dimension and tolerance are φ65.000 +0.018

-0.007 mm, with a single-side process allowance of 0.300 mm and a tolerance value of 0.025 mm.

(4) Semi-finish turning process dimensions and tolerances: φ64.000 -+0.1

0 mm, single-side process allowance 0.300 mm, tolerance value 0.040 mm.

-

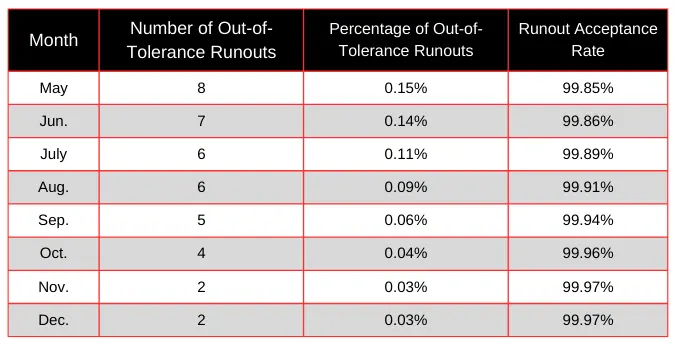

Production Results

Following these adjustments, statistical analysis of the implementation results showed that the qualification rate for the flange-end center hole of the crankshaft model increased to 99.96% (Table 2).

This achieved the target rate of 99.96% and fulfilled the overall objective.

Additionally, the qualification rate for keyway machining process holes and threaded hole drilling/tapping on Machine A flange-end center holes rose to 99.96%.

This met the target of 99.96% and indicated significant improvement in addressing the root cause.

Economically, this resulted in savings from rework losses, scrap losses, non-routine line stoppage losses, and overtime costs.

Conclusion

This study focused on the quality issue of center hole machining on the flange end of a specific crankshaft model at an automotive enterprise.

It systematically analyzed multi-dimensional factors, including equipment, process, and inspection, to establish a quality improvement methodology applicable to complex shaft components.

Results indicate that abnormal dynamic characteristics of the equipment during the keyway milling process and the thread drilling/tapping hole-A operation were the root cause of machining accuracy non-conformance.

These abnormalities contributed 82.3% to the issue.

This manifested as a synergistic effect between excessive radial runout of the spindle and residual metal chips in the fixture.

Optimizing the spindle-tool dynamic matching model and designing an automatic chip removal device increased the process pass rate from 98.03% to 99.96%.

This result validates the quality control theory that prioritizes equipment precision, with process parameters working synergistically.

This improvement introduced a process capability coupling analysis framework.

By quantifying the interactive effects of equipment status, process parameters, and preceding errors, it clarified quality control priorities for critical processes.

For instance, the quantitative relationship model between residual chips and clamping errors provides a theoretical basis for setting fixture cleaning frequencies.

In addition, establishing spindle dynamic characteristic detection standards offers reference methods for monitoring similar equipment.

This systematic improvement model not only resolves current issues but can also be extended to process optimization for complex components like camshafts and transmission gears.

Future developments may integrate digital twin technology to create adaptive process control systems, further enhancing the stability and intelligence of complex part manufacturing.

FAQ

What are the main challenges in machining automotive crankshafts?

Machining automotive crankshafts is challenging due to their complex geometry, including multiple crankpins and slender shafts. Over twenty machining processes, such as turning, drilling, and grinding, are required, with strict tolerances to prevent deviations that can amplify through the transmission system and cause bearing wear or cylinder block vibration.

Why is flange-end center hole precision critical in crankshaft manufacturing?

Flange-end center hole accuracy directly affects the dynamic balance of the crankshaft. Deviations can propagate downstream, causing abnormal bearing wear, increased vibration, and even crankshaft fractures during high-speed engine operation.

How do equipment conditions impact crankshaft machining quality?

Equipment conditions, particularly spindle runout and fixture cleanliness, play a decisive role. For example, a damaged probe or feedback cable can reduce the first-time quality (FTQ) from 99.31% to 98.03%. Optimizing spindle-tool dynamics and maintaining fixture cleanliness can significantly improve machining accuracy.

What multi-dimensional factors influence crankshaft machining quality?

Crankshaft quality is affected by six dimensions: personnel, machinery, materials, methods, environment, and measurement. Key contributors include spindle runout, residual metal chips, process capability (CPK), cutting force fluctuations, and adherence to inspection standards.

How was the root cause of flange-end center hole defects identified?

A systematic investigation traced 131 nonconforming parts, revealing that 97.7% of defects originated from the keyway milling and thread drilling/tapping process-A. Analysis of variance (ANOVA) quantified that spindle runout contributed 62.1% and fixture cleanliness 20.2%, confirming them as core factors.

What corrective measures improved crankshaft machining FTQ?

Targeted interventions included replacing damaged probes and feedback cables, optimizing rotational speed and feed rate, adding automatic fixture flushing, and controlling machining allowances. These measures increased the FTQ for critical processes to 99.96%, surpassing the BPD requirement of 99.3%.

How does process parameter optimization enhance machining accuracy?

Optimizing rotational speed, feed rate, and cutting parameters improves process stability and reduces tool path deviations. For instance, adjusting rotational speed from 900 r/min to 1,000 r/min and feed rate from 190 mm/min to 200 mm/min minimized chip accumulation and cutting force fluctuations.

What role does inspection and measurement play in crankshaft quality control?

Inspection ensures machining accuracy and compliance with metrology standards. For example, a coordinate measuring machine (CMM) with a calibration error below 0.002 mm verifies hole diameters, runout, and dimensional tolerances, while ANOVA quantifies the contribution of different factors to defects.

How do machining allowances and surface roughness affect crankshaft production?

Proper machining allowances and surface roughness control prevent rework and scrap. Single-side allowances for diameter machining are maintained between 2.6–3.4 mm, with surface roughness above 1.6 μm. Adjusting allowances based on material hardness and forging complexity ensures consistent quality.

Can this quality improvement methodology be applied to other automotive components?

Yes. The systematic approach, combining equipment precision, process parameter optimization, and fixture management, can be extended to complex components like camshafts and transmission gears. Future integration with digital twin technology can create adaptive process control systems for enhanced manufacturing stability.