Will learning coding help me operate CNC machines?

Will Learning Coding Help Me Operate CNC Machines?

As an engineer with a manufacturing background, you may find yourself wondering if learning coding can enhance your skills and help you operate CNC machines more effectively.

The Basics of CNC Machining

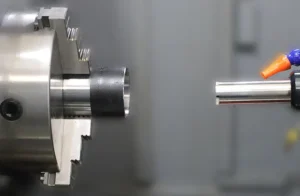

Before delving into the role of coding in CNC machining, let’s first understand the basics of how CNC machines operate.

CNC, which stands for Computer Numerical Control, is a technology that uses computer programs to control machine tools and automate the production process.

This technology has revolutionized the manufacturing industry by enabling precision, accuracy, and efficiency in producing complex parts and components.

The Role of Coding in CNC Machining

At the heart of CNC machining lies the programming code that directs the movements and actions of the machine.

This code, often written in languages such as G-code or M-code, instructs the CNC machine on how to perform various operations such as cutting, drilling, and milling.

By understanding and writing this code, operators can customize the machining process to meet specific requirements and achieve desired outcomes.

Benefits of Learning Coding for Operating CNC Machines

Learning coding can bring a myriad of benefits to engineers and operators in the CNC machining industry. Here are some ways in which coding skills can enhance your capabilities in operating CNC machines:

Customization and Optimization

One of the key advantages of knowing coding in CNC machining is the ability to customize and optimize machining operations.

By writing code tailored to the specific requirements of a part or component, operators can maximize efficiency, reduce waste, and achieve superior results.

This level of customization can lead to significant cost savings and improved productivity in the manufacturing process.

Troubleshooting and Debugging

Understanding coding can also facilitate troubleshooting and debugging when issues arise during the machining process.

By analyzing the code and identifying errors or inefficiencies, operators can quickly pinpoint the source of the problem and make necessary adjustments.

This level of technical proficiency can help minimize downtime and ensure seamless operations in a manufacturing environment.

Innovation and Automation

With coding skills, engineers and operators in CNC machining can explore innovative techniques and automation solutions to streamline production processes.

By leveraging coding knowledge, individuals can develop advanced algorithms, machine learning models, and automation scripts to optimize workflow, enhance precision, and drive continuous improvement in manufacturing operations.

Adaptability and Versatility

In today’s rapidly evolving manufacturing landscape, the ability to adapt to new technologies and methodologies is crucial for success.

Learning coding equips engineers and operators with the skills needed to stay ahead of the curve and embrace emerging trends in CNC machining.

By mastering coding languages and programming concepts, individuals can enhance their versatility and remain competitive in the industry.

Conclusion

In conclusion, learning coding can undoubtedly help you operate CNC machines more effectively and efficiently.

By acquiring coding skills, engineers and operators in the manufacturing industry can unlock new possibilities, enhance customization, troubleshoot issues, drive innovation, and stay adaptable in a dynamic environment.

Whether you are a seasoned professional or a newcomer to CNC machining, investing in coding education can open doors to endless opportunities and elevate your capabilities in the field.