Why is precision so critical in medical CNC machining?

Introduction

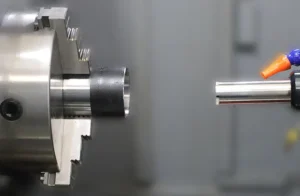

Medical CNC machining plays a vital role in the healthcare industry by producing precise components for medical devices and equipment.

The term ‘precision’ is often synonymous with CNC machining, and for a good reason.

Precision is crucial in medical CNC machining due to the intricate nature of medical devices and the need for accuracy in manufacturing.

The Importance of Precision in Medical CNC Machining

Precision in medical CNC machining refers to the ability of a machine to manufacture highly accurate components within tight tolerances.

This level of precision is essential in the medical industry, where even the slightest deviation from specifications can have serious consequences for patients.

Here are some reasons why precision is critical in medical CNC machining:

Patient Safety

One of the primary reasons why precision is crucial in medical CNC machining is patient safety. Medical devices, implants, and equipment must meet strict quality standards to ensure they perform effectively and safely.

Even a minor error in the manufacturing process can lead to device failure or malfunctions, posing a risk to patients’ health and well-being.

Precision machining ensures that medical components are produced with the highest level of accuracy and consistency, reducing the likelihood of defects and failures.

Performance and Reliability

Precision machining is essential for ensuring the performance and reliability of medical devices.

Components with precise dimensions and tolerances are more likely to function as intended, providing accurate results and optimal performance.

Whether it’s a surgical instrument or an implantable device, precision machining plays a critical role in ensuring that medical products meet quality and performance standards.

The reliability of medical devices is crucial in critical healthcare settings where accuracy and consistency are paramount.

Compatibility and Interchangeability

Another reason why precision is critical in medical CNC machining is compatibility and interchangeability.

Medical devices often consist of multiple components that must fit together seamlessly to function correctly.

Precision machining ensures that each component is manufactured to exact specifications, allowing for interchangeability and compatibility between parts.

This is particularly important in the case of implants and prosthetics, where precise fitting and alignment are essential for successful outcomes.

Regulatory Compliance

Medical device manufacturers are required to comply with strict regulatory standards to ensure the safety and effectiveness of their products.

Precision machining plays a crucial role in meeting these regulatory requirements by producing components that meet the specified tolerances and quality standards.

Non-compliance with regulatory requirements can result in costly fines, recalls, and damage to a company’s reputation.

Precision machining helps manufacturers maintain compliance with regulations and uphold the highest standards of quality and safety.

Cost Efficiency

While precision machining may require advanced equipment and specialized expertise, it can ultimately lead to cost savings in the long run.

By producing components with high accuracy and consistency, manufacturers can reduce the risk of rework, scrap, and rejects.

Precision machining also ensures that medical products have a longer lifespan and require less maintenance, ultimately leading to cost efficiency for both manufacturers and end-users.

Investing in precision machining can help companies improve their bottom line while delivering high-quality products to the market.

Conclusion

In conclusion, precision is a critical aspect of medical CNC machining due to its impact on patient safety, performance, reliability, compatibility, regulatory compliance, and cost efficiency.

The healthcare industry relies on precision machining to produce medical devices and equipment that meet the highest standards of quality and accuracy.

By prioritizing precision in the manufacturing process, medical device manufacturers can ensure that their products are safe, effective, and reliable for patients and healthcare providers.

Precision machining is not just a requirement; it is a necessity in the highly regulated and demanding field of medical manufacturing.