Can a Shapeoko CNC machine actually carve 3D objects?

Can a Shapeoko CNC Machine Actually Carve 3D Objects?

In the world of manufacturing and engineering, the ability to create 3D objects with precision and accuracy is of utmost importance.

With the advancements in technology, CNC (Computer Numerical Control) machines have become essential tools in the manufacturing industry.

One such CNC machine that has gained popularity for its versatility and performance is the Shapeoko CNC machine.

But the question remains – can a Shapeoko CNC machine actually carve 3D objects?

Understanding the Shapeoko CNC Machine

Before delving into whether a Shapeoko CNC machine can carve 3D objects, let’s first understand what a Shapeoko CNC machine is.

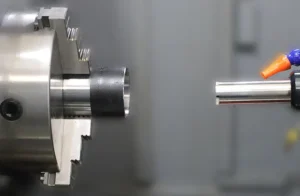

The Shapeoko is a desktop CNC machine that allows users to cut, carve, and mill a wide variety of materials such as wood, plastic, and aluminum with precision and accuracy.

It is a versatile tool that is used in various industries, including woodworking, prototyping, and small-scale manufacturing.

Capabilities of the Shapeoko CNC Machine

The Shapeoko CNC machine is known for its precision and versatility when it comes to cutting and carving 2D objects.

Its robust design and powerful motors allow it to accurately follow intricate designs and produce high-quality results.

However, when it comes to carving 3D objects, the capabilities of the Shapeoko CNC machine are put to the test.

Challenges of Carving 3D Objects with a Shapeoko CNC Machine

Carving 3D objects with a Shapeoko CNC machine presents a unique set of challenges.

Unlike 2D cutting, 3D carving requires the machine to move in multiple axes simultaneously, which can be more complex and demanding.

The Shapeoko CNC machine is a 3-axis machine by default, making it suitable for 2D cutting but less ideal for intricate 3D carving tasks.

Upgrade Options for 3D Carving with a Shapeoko CNC Machine

Despite its limitations in 3D carving, there are upgrade options available for the Shapeoko CNC machine that can enhance its capabilities.

One popular upgrade is adding a 4th axis to the machine, which allows for more complex and intricate 3D carving operations.

By incorporating a 4th axis, the Shapeoko CNC machine can achieve greater precision and control when carving 3D objects.

Software Solutions for 3D Carving with a Shapeoko CNC Machine

In addition to hardware upgrades, software solutions play a crucial role in enabling the Shapeoko CNC machine to carve 3D objects effectively.

There are specialized CAM (Computer-Aided Manufacturing) software programs available that are designed specifically for 3D carving.

These programs allow users to create detailed 3D models and generate toolpaths for the Shapeoko CNC machine to follow, ensuring accurate and precise carving results.

Best Practices for 3D Carving with a Shapeoko CNC Machine

When it comes to carving 3D objects with a Shapeoko CNC machine, certain best practices can help achieve optimal results.

It is essential to choose the right materials and cutting tools for the job, as well as to calibrate the machine accurately.

Additionally, proper setup and alignment of the workpiece are crucial for successful 3D carving operations.

Conclusion

While the Shapeoko CNC machine is primarily designed for 2D cutting and carving tasks, with the right upgrades and software solutions, it is possible to carve 3D objects effectively.

By understanding the challenges and implementing best practices, engineers and manufacturers can leverage the capabilities of the Shapeoko CNC machine to create intricate and detailed 3D objects with precision and accuracy.

1 thought on “Can a Shapeoko CNC machine actually carve 3D objects?”

Appreciate the breakdown—it’s clear and practical.