Can a CNC plasma cutter produce small holes accurately?

Can a CNC Plasma Cutter Produce Small Holes Accurately?

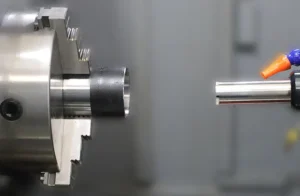

When it comes to precision cutting in the manufacturing industry, CNC plasma cutters have become a popular choice. These machines offer high-speed cutting capabilities with excellent accuracy.

However, one question that often arises is whether a CNC plasma cutter can produce small holes accurately.

Understanding CNC Plasma Cutting Technology

CNC (Computer Numerical Control) plasma cutting is a process that utilizes a high-velocity jet of ionized gas to melt and expel material from a workpiece.

The CNC aspect of the technology allows for precise control over the cutting process, with the machine following a pre-programmed design to cut through the material with accuracy.

Challenges of Cutting Small Holes

When it comes to cutting small holes, there are several challenges that manufacturers face. One of the main difficulties is achieving the desired hole diameter without any deviation or distortion.

Additionally, factors such as the material type, thickness, and cutting speed can all impact the accuracy of the hole.

Accuracy of CNC Plasma Cutters

CNC plasma cutters are known for their exceptional accuracy when it comes to cutting through materials. These machines can achieve high levels of precision, even when cutting complex shapes and intricate designs.

However, when it comes to creating small holes, there are certain limitations that need to be taken into consideration.

Factors Affecting Hole Accuracy

Several factors can affect the accuracy of small holes produced by a CNC plasma cutter. These include:

- 1. Nozzle Size: The size of the cutting nozzle plays a crucial role in determining the diameter of the hole. Smaller nozzles can produce smaller holes with greater accuracy.

- 2. Material Thickness: Thicker materials may require more power and slower cutting speeds, which can affect the accuracy of the hole.

- 3. Cutting Speed: The speed at which the CNC plasma cutter moves across the material can impact the quality of the cut, especially when it comes to small holes.

- 4. Pierce Delay: The time it takes for the plasma arc to pierce through the material can also affect the accuracy of the hole.

Strategies for Achieving Small Hole Accuracy

Despite the challenges associated with cutting small holes, certain strategies can help improve accuracy when using a CNC plasma cutter. These include:

- 1. Use a Smaller Nozzle: Opt for a smaller cutting nozzle to achieve more precise holes.

- 2. Adjust Cutting Parameters: Fine-tune the cutting parameters such as cutting speed, pierce delay, and power settings to optimize hole accuracy.

- 3. Consider Material Properties: Take into account the type and thickness of the material being cut to ensure the best results.

- 4. Perform Test Cuts: Before cutting the final piece, perform test cuts on a scrap material to fine-tune the cutting parameters.

Conclusion

While CNC plasma cutters are capable of producing accurate cuts, including small holes, achieving optimal accuracy requires careful consideration of various factors.

By understanding the challenges associated with cutting small holes and implementing the right strategies, manufacturers can leverage CNC plasma cutting technology to create precise and intricate designs with ease.