CNC milling is a process that cuts material from blocks. It helps make detailed shapes with great accuracy. This method is important in industries needing perfect precision. For example, aerospace companies use it for strong, light parts. Car makers rely on it for exact parts, making up 29.7% of the CNC milling market in 2024. The medical field uses it to create tricky devices. As demand rises, the vertical CNC milling machine market may hit $13.7 billion by 2032.

Key Takeaways

- CNC milling is a way to shape materials exactly. It is important for industries like airplanes and medical tools.

- Knowing the parts of a CNC milling machine helps it work well and correctly.

- CAD and CAM software make designing easier by turning ideas into machine steps.

- Picking the right materials and sizes is key to making good-quality parts with CNC milling.

- Taking care of CNC machines and setting them up properly can lower waste and save money.

What Is CNC Milling?

Definition and Key Features

CNC milling is a process controlled by computers. It removes material from a solid block to form shapes. Rotating tools cut the material to make exact designs. This method works with metals, plastics, and wood. It uses CNC to move tools automatically for accuracy and speed.

A key feature of CNC milling is making complex parts. It creates detailed shapes that are hard to make by hand. It also repeats the same design perfectly every time. This is very useful for industries like aerospace and medical devices.

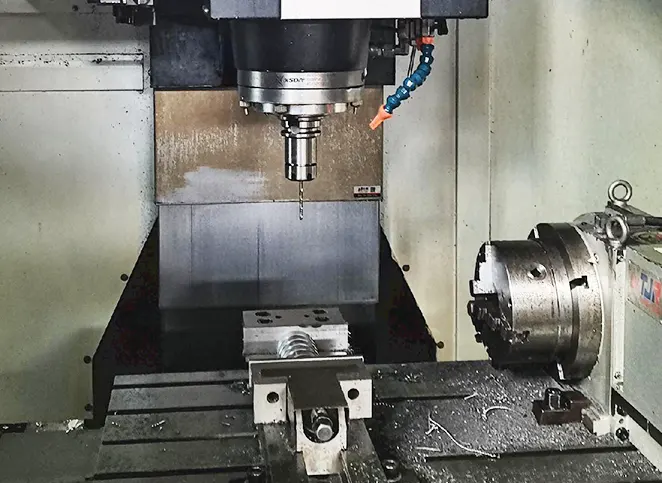

Components of a CNC Milling Machine

A CNC milling machine has many important parts. These parts work together to shape materials. They include:

- Spindle: Holds and spins the cutting tool.

- Control panel: Lets you program and run the machine.

- Column: Supports the machine’s structure.

- Saddle: Helps the worktable move sideways.

- Worktable: Holds the material being shaped.

- Knee: Adjusts to support the saddle and table.

- Ram: Found in vertical machines, it holds the spindle.

Each part helps the machine work smoothly and accurately.

Materials Used in CNC Milling

CNC milling works with many types of materials. It can shape metals like aluminum, steel, and titanium. These are used in cars and airplanes. Plastics like ABS and polycarbonate are also good for CNC milling. They are great for lightweight parts and prototypes. Even wood and glass can be shaped using this process.

This flexibility makes CNC milling useful for many industries. Whether you need strong metal parts or detailed plastic pieces, CNC milling can do the job well.

How CNC Milling Works

Designing the CAD Model

CNC milling starts with making a CAD model. This is a digital plan showing the part’s shape and size. CAD software helps create detailed designs that are hard to draw by hand. For example, tools like Mastercam are now easier to use. They help students and experts make designs faster. With CAD, you can see your part before making it. This helps ensure it is correct and avoids mistakes.

Converting to CAM Program

After finishing the CAD model, it is turned into a CAM program. This step changes the design into machine instructions called G-code. The G-code tells the machine how to cut and move. It also sets the speed for cutting. This step connects the design to the machine. Modern CAM software makes this step simple. It lets you focus on improving your design instead of worrying about the machine setup.

Step-by-Step Process

CNC milling follows clear steps to make parts accurately. Here’s how it works:

- Make a CAD Model: Use CAD software to design the part.

- Turn CAD into CAM: Create G-code from the CAD model.

- Prepare the Machine: Secure the material and set up the machine.

- Run the CNC Program: Start the G-code to begin milling.

- Finish the Product: Polish and check the final piece.

Each step is important to turn your idea into a real object. By following these steps, you can make high-quality parts every time.

Machine Setup and Operation

Getting a CNC milling machine ready needs careful steps. Good preparation helps avoid mistakes and ensures accurate results. Follow these simple steps to set up your machine:

- Check the Machine: Look for damage or wear on parts. Make sure the spindle, worktable, and tools are clean and working well.

- Secure the Material: Place the material on the table. Use clamps or a vise to keep it from moving.

- Add the Cutting Tool: Pick the right tool for your design. Insert it into the spindle and tighten it securely.

- Set the Zero Point: Adjust the X, Y, and Z axes to mark where cutting starts.

- Load the Program: Upload the G-code file from your CAM software. Check the code for mistakes before starting.

To make your machine work better, try these tips:

- Use OPC UA servers for safe and smooth device communication.

- Organize data points with custom tag structures.

- Add edge gateways to process data and reduce network strain.

- Keep logs to track how the machine performs over time.

Also, create easy-to-read dashboards to watch important metrics. Set alarms to warn you about problems quickly. These tools help fix issues fast and reduce downtime.

After setup, start the machine and watch it closely. Listen for strange sounds during cutting. If something seems wrong, stop the machine and fix it. With proper setup, CNC milling can make accurate and high-quality parts every time.

Types of CNC Milling Machines and Processes

Vertical Milling Machines

Vertical milling machines are very common in CNC milling. Their spindle points up and down, moving the cutting tool vertically. This setup is great for making detailed designs and small features. Vertical mills are used for drilling, slotting, and angled cuts. They work best for small projects needing accuracy.

Vertical mills cost less and are simpler than horizontal ones. But they are slower for making many parts quickly. The table below shows how vertical and horizontal mills differ:

| Performance Aspect | Vertical Milling Machines | Horizontal Milling Machines |

|---|---|---|

| Cost | Lower | Higher |

| Complexity | Easier to use | More advanced |

| Versatility | Best for small tasks | Better for big tasks |

| Speed | Slower for large jobs | Faster for large jobs |

| Suitability | Great for fine details | Best for heavy materials |

Horizontal Milling Machines

Horizontal milling machines have a spindle that lies flat. This lets them handle bigger and heavier materials easily. They are used for cutting grooves, slots, and gears. Horizontal mills are great for making many parts at once.

These machines are faster than vertical mills but still precise. Their design helps clear away chips using gravity. This improves the surface finish and protects the cutting tools. If you need to make many parts quickly, horizontal mills are a smart choice.

Specialized Milling Machines

Specialized milling machines are made for specific jobs. Examples include 3-axis, 4-axis, and 5-axis machines. A 3-axis machine is good for simple tasks. A 4-axis or 5-axis machine handles more complex shapes. For instance, 5-axis machines can create very detailed parts.

These machines are useful for both prototypes and mass production. Industries like aerospace, cars, and medical devices rely on them. Picking the right specialized machine ensures precision and efficiency for your project.

3/4/5-Axis Milling

Understanding 3-axis, 4-axis, and 5-axis machines is important. Each type has different abilities and precision levels. This helps you pick the right one for your project.

A 3-axis machine is the simplest option. It moves the cutting tool in three directions: X, Y, and Z. This is good for easy tasks like drilling or cutting slots. But for complex shapes, it needs re-clamping, which lowers accuracy.

A 4-axis machine adds a rotating axis. This lets the material turn during cutting. It improves accuracy by reducing re-clamping. It also allows for more detailed designs, like gears or curved parts.

A 5-axis machine is the most advanced. It moves the tool in five directions, including two rotations. This setup handles complex shapes in one go. It saves time and reduces mistakes. Industries like aerospace and medical devices use 5-axis machines for precise work.

Here’s how their abilities and precision compare:

| Machine Type | Abilities | Precision Level |

|---|---|---|

| 3-Axis | Simple tasks | Basic |

| 4-Axis | Detailed work | Better |

| 5-Axis | Complex shapes | Very high |

Accuracy improves as machines get more advanced:

| Machine Type | Accuracy Boost | Why It Improves |

|---|---|---|

| 3-Axis | Basic | Re-clamping causes more errors |

| 4-Axis | Moderate | Fewer re-clampings reduce mistakes |

| 5-Axis | High | One setup avoids errors completely |

Pick your machine based on your project’s needs. Use 3-axis for simple parts. Choose 5-axis for detailed or high-precision tasks.

Advantages of CNC Milling

Precision and Accuracy

CNC milling is very precise, making parts with tight tolerances. This accuracy is crucial for industries like aerospace and medical devices. Even small errors can affect how these parts work. CNC milling avoids human mistakes by using programmed instructions. This ensures you get consistent and reliable parts every time.

To keep this precision, use good cutting tools and check machine settings. Regularly inspect tools and parts to confirm they meet exact measurements. These steps help improve the quality and function of your parts.

Tip: Adjust machine settings and tool paths to improve accuracy.

Efficiency and Automation

CNC milling makes production faster with automated processes. Once programmed, the machine handles complex tasks without help. This saves time and increases the number of parts made.

Here’s how CNC milling improves efficiency:

- Automated systems work faster and need less manual effort.

- Parts are consistent, reducing waste and rework.

- Easy programming lets you focus on better designs.

| Aspect | Description |

|---|---|

| Precision | CNC machines provide high accuracy, important for exact measurements. |

| Efficiency | Automation speeds up work and reduces the need for manual labor. |

The CNC milling market is growing fast, from $8.5 billion in 2023 to $13.7 billion by 2032. Automation is a big reason for this growth.

Reduced Waste and Labor Costs

CNC milling cuts waste by using materials efficiently. It only uses what’s needed for each part, saving money. Fewer rejected parts also lower costs.

Using lean manufacturing can make these benefits even better. This method reduces waste and improves efficiency. Just-in-time manufacturing also helps by managing inventory and cutting storage costs.

| Strategy | Impact on Costs |

|---|---|

| Lean manufacturing | Reduces waste and boosts efficiency |

| High part quality rate | Saves material and lowers waste |

By combining accuracy, speed, and less waste, CNC milling is a smart and cost-saving choice for modern production.

Post-Processing

After CNC milling, parts often need extra work. This step ensures the part looks good and works well.

Common Post-Processing Techniques

- Deburring: Milling can leave sharp edges or burrs. Use tools like files or sandpaper to remove them. This makes the part safer and smoother.

- Surface Finishing: Add finishes like polishing or painting to protect the part. For example, anodizing aluminum prevents rust and improves durability.

- Heat Treatment: Heat can make materials stronger and tougher. This is often done for steel parts.

- Inspection and Quality Control: Check the part’s size and shape with tools like calipers. This ensures it matches the design perfectly.

Tip: Always check the part after each step. This avoids problems later.

Why Post-Processing Matters

Skipping post-processing can cause problems. Sharp burrs can hurt people, and untreated surfaces may rust. Post-processing makes parts safe, strong, and nice to look at.

Automating Post-Processing

Some post-processing tasks can be automated. For example, robots can remove burrs quickly and evenly. This saves time and reduces costs.

Spending time on post-processing improves the quality of CNC parts. It also helps meet industry standards.

Designing for CNC Milling

Tips for Easy Manufacturing

Planning is key to making CNC milling simple and cost-friendly. Use these tips to make parts easier to produce:

- Pick materials like aluminum or plastics. These are easy to machine and help tools last longer.

- Use standard material sizes. This reduces waste and makes machining faster.

- Split big parts into smaller sections. Smaller pieces are easier to machine and less likely to have errors.

Here are more ways to improve your design:

| Design Tip | Why It Helps |

|---|---|

| Fewer Tool Changes | Saves time and boosts efficiency. |

| Keep Designs Simple | Reduces mistakes and lowers production costs. |

| Plan Efficient Tool Paths | Cuts machining time and improves surface quality. |

| Even Wall Thickness | Prevents warping and keeps dimensions stable. |

| Add Fillets and Rounded Edges | Protects tools and makes smoother finishes. |

Using these ideas can lower costs, speed up production, and make parts more reliable.

Tip: Talk with machinists to ensure your design fits their tools and methods.

Avoiding Design Errors

Some mistakes can slow down CNC milling or cause problems. Avoid these common errors:

- Complicated designs take longer to machine and may cause errors. Keep designs simple.

- Forgetting surface finish needs can increase costs. Only ask for finishes that are necessary.

- Not planning for tool access can leave parts unfinished. Make sure tools can reach all areas.

These mistakes can lead to wasted materials and higher costs. Fixing them early improves quality and reduces waste.

Note: Always check your design for manufacturing issues before starting production.

Picking Materials and Tolerances

Choosing the right material and tolerance is very important for CNC milling. Think about these points when selecting materials:

- Match the material to where it will be used. For outdoor parts, pick materials that resist rust and water.

- Consider stress and weight. Make sure the material can handle heavy loads without bending.

- Check how heat affects the material. Pick one that stays strong in high temperatures.

Tolerances also matter. CNC milling usually achieves ±0.005 inches (±0.13 mm). Tighter tolerances cost more, so balance accuracy with your budget. Use standards like ISO 2768 to keep designs consistent.

Tip: Work in a room with stable temperature. This helps keep machining accurate and improves tolerance results.

Cost Considerations in CNC Milling

Factors Affecting CNC Milling Costs

Many things affect how much CNC milling costs. Knowing these can help you save money.

- Equipment Costs: CNC machines are pricey to buy and fix. Advanced machines cost more and increase part prices.

- Material Prices: Material costs depend on type and availability. Metals like titanium cost more than aluminum or plastics.

- Design Complexity: Complicated designs take longer to machine, raising costs.

- Machining Time: Longer machining times use more energy and labor. Slow cycles lower productivity, so improving operations is key.

For instance, the CNC milling market may grow from $81.8 billion in 2024 to $104.3 billion by 2031. But high machine costs and upkeep remain tough for manufacturers.

Balancing Cost and Quality

Finding a balance between cost and quality is important. Good parts work better but often cost more. You can balance this by being efficient and reducing mistakes.

Quality checks are very important. They ensure parts meet standards, cutting waste and rework. Watching processes closely keeps results consistent. Studies show better training and improved methods can lower costs a lot.

| Study | Focus | Methodology |

|---|---|---|

| Shin and Joo | E0300 alloy steel | Lowering production costs in turning |

| Cakir and Gurarda | HSS material | Improving machining conditions |

| Srivastava et al. | Aluminum LM25 alloy | Checking CNC turning settings with GRA |

By focusing on quality, you can cut waste and save money while keeping efficiency high.

Strategies to Reduce Costs

Here are ways to lower CNC milling costs without losing quality:

- Optimize Machining Parameters: Use the right speeds and feeds to save time. This reduces idle time and boosts productivity.

- Choose Cost-Effective Materials: Pick materials like aluminum or plastics. They are easier to machine and save on tool wear.

- Simplify Designs: Avoid very complex designs. Simple designs are quicker and cheaper to make.

- Invest in Maintenance: Keep machines in good shape to avoid breakdowns and work smoothly.

High rejection rates waste money. Fixing processes and cutting defects saves materials and labor. Running things efficiently lowers costs and improves part quality.

CNC milling is known for being precise and efficient. It can also handle tricky designs easily. This method gives better accuracy, faster work, and less waste than doing it by hand.

- Main benefits include:

- Reliable results using computer controls

- Easy to work with many materials

- Quicker production needing fewer workers

| CNC Milling Type | Advantages | Drawbacks |

|---|---|---|

| 3-axis CNC Milling | Accurate and affordable per piece | Not ideal for very complex shapes |

| 5-axis CNC Milling | Great for detailed, complex designs | Costs more and uses bigger machines |

Smart planning and managing costs help you get the most out of CNC milling. Use this process to reach your production goals effectively.