As modern manufacturing moves toward intelligent and digital production, the performance requirements for CNC tools have increased. Mechanical manufacturers must correctly apply CNC tooling technologies to optimize machining processes.

Cutting tools are the direct executors of machining on machine tools—without them, machine tools cannot function.

Emphasizing tooling begins with tool selection. One should choose new tool materials that match the workpiece material, offer sufficient precision, and advanced structure. When calculating tool investment, the cost per part should be used as the comparison basis.

Additionally, optimizing the machining program is essential to fully exploit the tool’s potential and achieve high quality, productivity, and tool life.

CNC Tooling Technology

CNC tooling is a critical component for achieving cutting functions on metal cutting machine tools. Structurally, the metal cutting tool system consists of cutting tools and a tool holder system—the latter serves as the carrier for the former.

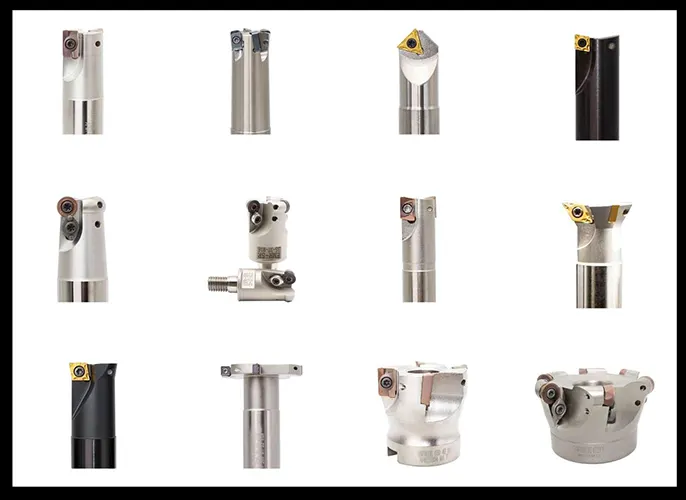

Cutting tools include indexable tools, solid carbide tools and inserts, superhard tools, and complex tools. The tool system includes various tool holders that connect cutting tools with CNC machines.

CNC tools feature:

- High durability and reliability

- Easy control of cutting conditions

- High positioning and repeatability accuracy

- Automation of tool and insert positioning and tool changes

CNC tooling technology must meet the modern manufacturing demands for:

- High cutting efficiency

- High positioning accuracy

- Strong reliability

Selection of CNC Tools

Principles for CNC Tool Selection

Tool selection is a key part of CNC machining. It must consider:

- Machine capability

- Material and properties of the workpiece

- Type of machining process

- Workpiece specifications

- Tool’s cutting load capacity

- Other relevant factors

Selection principles include:

“Easy installation and adjustment, good rigidity, high durability and precision. Under the premise of meeting processing requirements, choose the shortest possible tool holder to enhance rigidity.”

Selection of CNC Turning Tools

Tool Holder Selection

The basic dimensions of a tool holder include length, width, and tip height. Selection should consider:

- Workpiece diameter

- Machine tool turret

- Clamping method

- Cutting layer cross-section

- Tool overhang

- Insert clamping system

- Tool holder length is determined by bore depth, overhang, and clamping length.

For internal turning, the tool should extend just past the bore depth.

For external turning, overhang should be less than 1.5 times the holder height.

Selection of Turning Tools

(1) Turning Tool Types

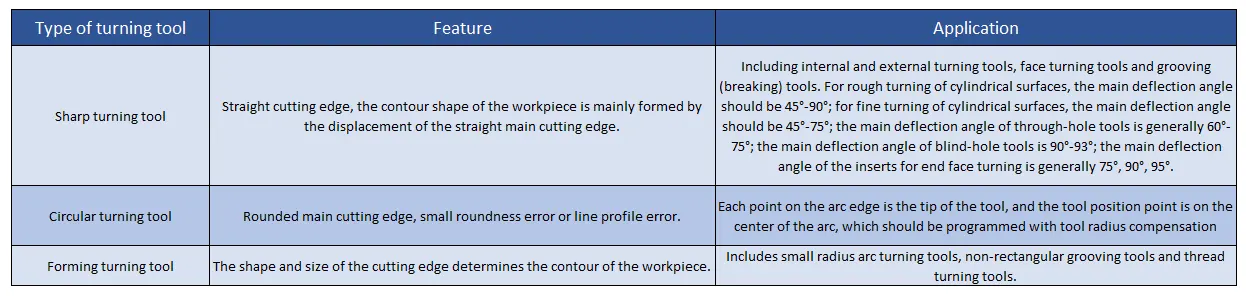

CNC turning tools are chosen based on the surface shape and cutting method of the workpiece. (Refer to Table 1: CNC turning tool types and applications.)

(2) Tool Nose Radius

In general, a larger nose radius enhances tool tip strength. The nose radius also affects:

- Cutting efficiency

- Workpiece accuracy

- Surface roughness

When selecting tools, consider the relationship between nose radius and maximum feed rate:

Ensure: nose radius ≥ 1.25 × maximum feed rate.

- For roughing: use 0.8 mm – 2.4 mm

- For semi-finishing: use 0.4 mm – 1.2 mm

- For finishing: use 0.2 mm – 0.8 mm

Selection of Machining Center Tools

Machining centers mainly perform:

- Drilling

- Boring

- Reaming

- Milling

Tools include general-purpose tools and tool holders that match the machine spindle taper.

To improve tool rigidity, choose shorter tool holders and tools, provided processing requirements are met.

When applying tools, estimate the tool length based on:

- Workpiece size

- Clamping position on the worktable

- Distance from spindle face to the table surface or table center

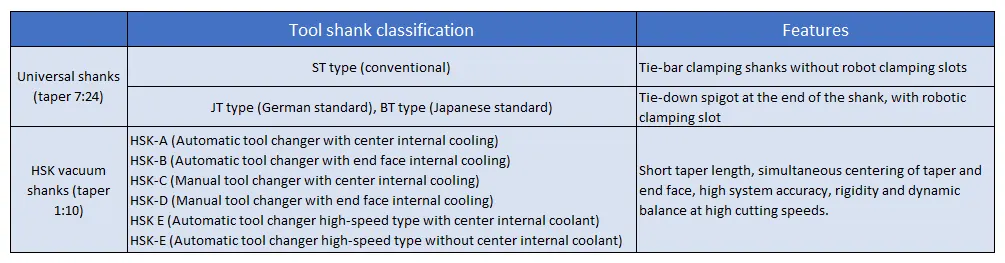

Tool holders are selected based on:

- Spindle taper

- Size

Refer to Table 2: Tool holder types and characteristics for machining centers.

Hole Machining Tools

- For hole diameters < Φ80 mm:

Use indexable insert drills, solid carbide drills, U drills, core drills, reamers, and taps. - For hole diameters > Φ80 mm:

Use boring tools. The selection must consider the rigidity of the boring bar to prevent or reduce vibration. Key points:

① Use short tool holders.

If the working length-to-diameter ratio is low, steel holders may be used. For high-precision holes, carbide holders are better; use vibration-damping holders for large holes.

② Choose boring bars close to the bore diameter.

③ Use lead angles of 75°–90° where possible.

④ For finishing: use positive rake inserts;

For roughing: use negative rake inserts.

⑤ For deep blind holes, use compressed air or coolant for chip evacuation and cooling.

Face and Groove Milling Tools

When selecting face and groove milling tools, the tool dimensions must match the surface dimensions of the workpiece.

For peripheral contour machining of planar parts, end mills are commonly used.

For machining three-dimensional curved surfaces or variable angle profiles, ball nose mills, circular mills, tapered mills, and disk mills are typically used.

For small flat surfaces or steps, carbide insert mills are often selected.

Keyway cutters are used for milling keyways.

High-speed steel end mills are used for machining bosses and grooves.

For rough surfaces or rough hole machining of castings, corn-style carbide insert mills are used.

Flat end or ball nose mills are selected for free-form surfaces.

Selection guidelines for end mills include:

Tool radius should be 0.8 to 0.9 times the smallest curvature radius of the internal contour of the part, and 4 to 6 times the machining height.

- When machining deep grooves, the cutting edge length should exceed the part height by 5 mm–10 mm.

- For external profiles and through-grooves, the cutting edge length should be greater than the sum of the part height and the bottom corner radius by 5 mm–10 mm.

- For ribs, the tool diameter should be 5 to 6 times the rib thickness to ensure sufficient rigidity.

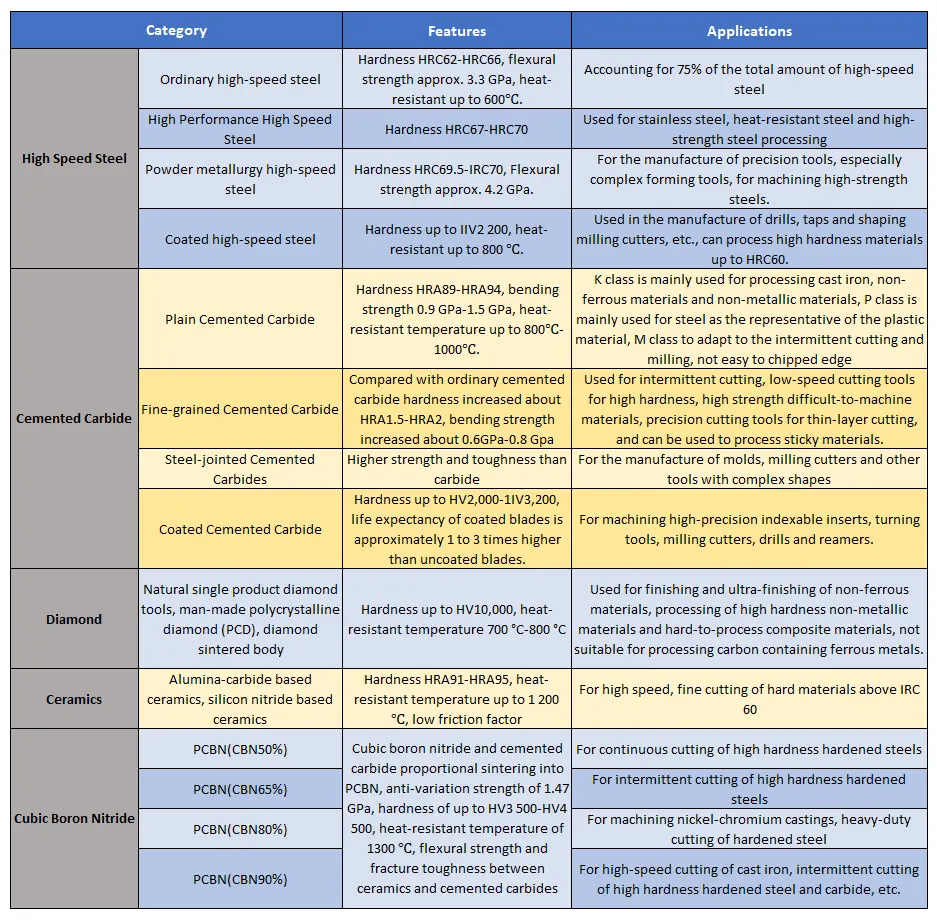

Selection of Tool Materials

Tool material refers to the material used in the cutting portion of the tool, and its performance directly affects surface quality, cutting efficiency, and tool life.

Today, cemented carbide tools are gradually replacing high-speed steel tools, and the use of coated tools is becoming more common. The application of PCD, PCBN, and diamond-coated tools is rapidly growing.

Selection of Cutting Parameters

Cutting parameters are critical in selecting CNC tools. Cutting speed depends primarily on:

- Tool durability

- Workpiece material

- Economic factors of cutting

- Machine load capacity

Spindle speed is determined by the cutting speed.

Feed rate selection should consider:

- Tool characteristics

- Required machining precision

- Surface finish

- Workpiece material

The final feed is calculated based on spindle speed and the number of cutter teeth.

Depth of cut is selected based on:

- Rigidity of the process system

- Allowances for each operation or process step

CNC Tool Selection Case Studies

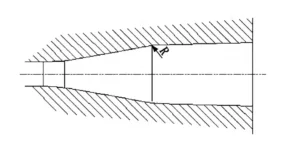

CNC Turning of Deep Variable-Diameter Inner Taper Hole

As shown in Figure 1, the part is a long cylindrical piece made from high-strength alloy steel. The inner hole consists of three connected conical sections and one cylindrical hole, with arcs at the transitions.

High requirements exist for:

- Coaxiality

- Roundness

- Dimensional precision

- Surface roughness

Traditional process using lathes and tools:

- Rough and finish boring the through hole

- Rough and finish boring the large cone

- Semi-finish boring each of the three cones from outside in

- Reaming

- Polishing the conical holes

Tools used included 75° boring bars and three dedicated large reamers. Issues included:

- Frequent tool changes and regrinding

- High tool costs

- Poor quality

With the introduction of internally cooled anti-vibration boring bars and CNC boring heads, a new CNC machining strategy was developed:

- Rough and finish bore the through hole

- Rough, semi-finish, and finish bore the taper profile axially in layers

The toolpath was revised, and tools like internally cooled anti-vibration boring bars and boring heads were used (Figures 2 and 3).

- Roughing and semi-finishing: 75° lead angle, 0.8 mm nose radius

- Finishing: 93° lead angle, 0.4 mm nose radius

- All inserts were coated carbide

Result:

The CNC tool application merged several processes, improved machining quality, and reduced manufacturing costs.

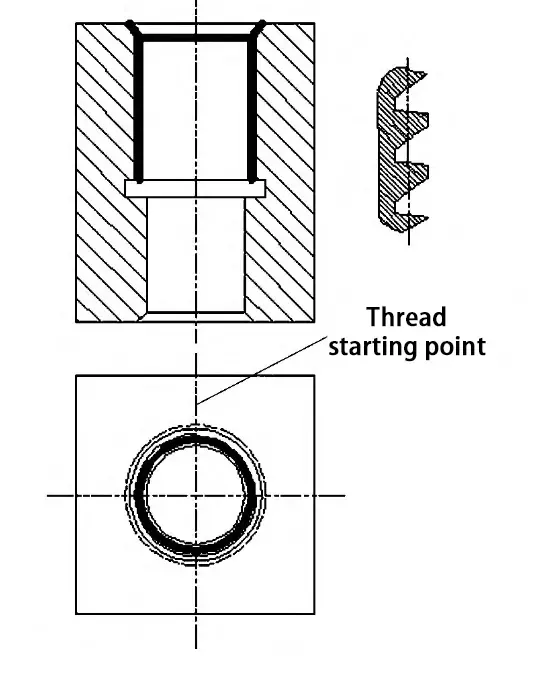

CNC Milling of Threaded Components

The transmission component has a rectangular body with a stepped internal trapezoidal thread hole (see Figure 4).

- Cutting begins at a preset pitch diameter point

- Made of high-strength alloy steel, HRC40 hardness

Key points in CNC machining:

- Processing the trapezoidal thread and the back-off groove

Traditional method used a fixture on a horizontal lathe, which had issues with:

- Complex clamping and tool alignment

- Low efficiency

- Safety risks due to unbalanced fixture weight

Optimized approach:

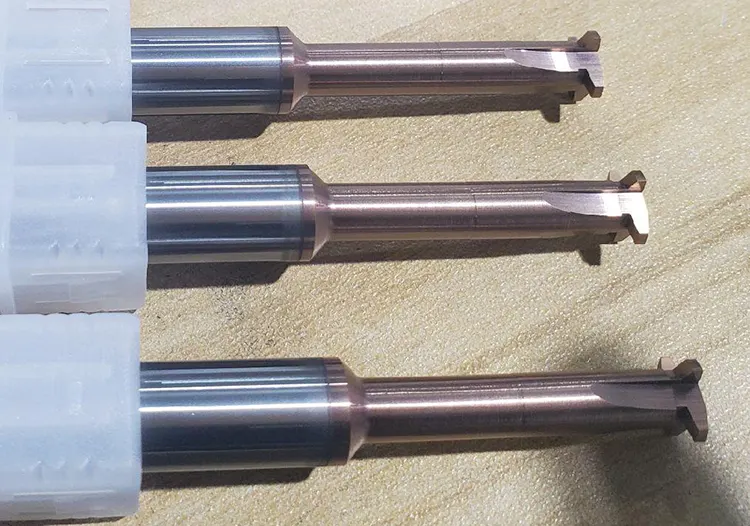

Using a machining center and CNC system, and based on the component’s dimensions and thread characteristics, the solution used:

- CNC internal thread milling cutter with rotary edges (Figure 5)

- CNC ring groove milling cutter (Figure 6)

- High-speed cutting

Due to high milling forces, deformation can occur during machining.

Thread milling is better suited for large-diameter parts, and coated carbide inserts are used.

Conclusion

As manufacturing advances toward digitalization and intelligence, CNC tool technology plays a crucial role in enhancing process efficiency, precision, and reliability.

The selection of CNC tools must align with machining requirements, workpiece materials, and process characteristics.

Using modern cutting tools such as coated carbide, PCD, PCBN, and advanced tool holders, manufacturers can:

- Consolidate machining steps

- Improve surface quality

- Extend tool life

- Reduce overall costs

The two case studies demonstrate how applying the right CNC tooling strategies can simplify complex processes and greatly improve production performance. Proper tool selection is not just a technical necessity—it is a competitive advantage in modern manufacturing.

FAQ

Why is CNC tooling important in modern manufacturing?

CNC tooling plays a vital role in achieving high precision, efficiency, and automation in modern metal cutting operations. As manufacturing shifts toward digital and intelligent systems, proper tool selection directly impacts part quality, production speed, and cost control.

What are the key principles for selecting CNC tools?

CNC tool selection should consider machine capability, workpiece material, machining process type, and cutting loads. The goal is to ensure rigidity, ease of adjustment, and durability—favoring the shortest possible tool holders for enhanced stability.

How do you choose the right CNC turning tool?

CNC turning tools are selected based on workpiece shape and cutting method. Considerations include tool holder dimensions, overhang limits, insert type, and nose radius. Larger nose radii improve tip strength, while smaller radii offer better surface finish.

What are the best practices for selecting tools for machining centers?

Tool selection for machining centers depends on the operation (drilling, boring, reaming, or milling), spindle taper, and workpiece setup. For optimal performance, use shorter tool holders and ensure tool lengths are calculated precisely based on clamping and spindle position.

What types of tools are used for hole machining in CNC processes?

For holes smaller than Φ80 mm, use solid carbide drills, U drills, reamers, and taps. For holes larger than Φ80 mm, boring tools are preferred. Tool rigidity, vibration resistance, and coolant flow are critical to ensuring accuracy and tool life.

How do I select face and groove milling tools for CNC machining?

Select tools that match the surface geometry and size of the workpiece. Use end mills for flat surfaces, ball nose or tapered mills for 3D curves, and corn-style insert mills for roughing cast surfaces. Ensure tool dimensions meet depth and curvature requirements.

Which tool materials are best for high-performance CNC machining?

Cemented carbide and coated tools have largely replaced high-speed steel due to better wear resistance and cutting performance. PCD, PCBN, and diamond-coated tools are ideal for ultra-hard materials and achieving superior surface finishes.

How do cutting parameters affect CNC tool selection?

Cutting parameters such as speed, feed rate, and depth of cut must align with tool material, workpiece type, and machining goals. Accurate parameter selection ensures optimal tool life, surface finish, and production efficiency.

How can CNC tool selection reduce manufacturing costs?

By using advanced tools like coated carbide inserts, anti-vibration boring bars, and optimized toolpaths, manufacturers can consolidate operations, reduce tool changes, improve accuracy, and minimize downtime—leading to lower overall production costs.

What are real-world examples of effective CNC tool strategies?

Case studies like deep taper hole boring and internal thread milling show how selecting the right CNC tools and toolholders can streamline complex operations, improve surface quality, reduce tool wear, and enhance production efficiency.