High pressure die casting is a quick way to make metal parts. It creates detailed designs by injecting liquid metal into molds fast, at 30 to 100 m/s. This method makes thin parts, sometimes just 1 mm thick. It is great for lightweight designs. Unlike older methods, it reduces waste by shaping parts almost perfectly. It can handle tricky details, giving you strong, high-quality parts for tough jobs.

How High Pressure Die Casting Works

Mold Preparation

Before starting, the mold must be prepared properly. This step helps make good-quality parts. The mold is heated to certain temperatures, like 200°C for inserts and 100°C for the base. This stops it from cracking due to heat changes. Thermocouples are used to check and control the temperature. After nine heating cycles, the mold is ready to use.

A release agent is added to the mold’s surface. This stops the metal from sticking and helps the mold last longer. The filling speed is kept under 0.5 m/s. This prevents air bubbles that can ruin the part.

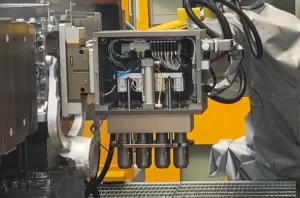

Metal Injection Process

Molten metal is pushed into the mold at very high pressure, between 1,500 and 32,000 psi. This pressure fills the mold quickly and evenly. The process only takes a few seconds, making it fast.

After the mold is filled, the metal cools and hardens. Cooling time depends on the metal and mold temperatures. Once solid, ejector pins push the part out of the mold. Extra material, called flash, is removed during cleaning. This step ensures the part is the right size and shape.

Hot Chamber System

The hot chamber system works best for metals like zinc that melt easily. In this system, the metal stays melted between castings, which saves time. The injection part is placed in the molten metal, speeding up production.

This system makes parts with smooth surfaces and accurate sizes. It also reduces shrinking, so parts keep their shape. The hot chamber system is important for making many parts quickly.

Cold Chamber System

The cold chamber system works for metals that melt at high heat, like aluminum and magnesium. In this process, melted metal is poured into a separate chamber before being injected into the mold. This setup keeps the injection system cooler, which helps the equipment last longer.

High pressure is used to fill the mold, making strong and dense parts. These parts are tough and work well for heavy-duty uses. For instance, aluminum parts made this way are affordable and durable. The cold chamber system also creates detailed designs, making it great for complex shapes.

Unlike the hot chamber system, this method takes more time because the molten metal must be moved manually. But the extra time is worth it. The parts are stronger, more detailed, and perform better in tough conditions.

Part Removal and Trimming

When the metal hardens, the part is ready to come out. Ejector pins gently push the part out of the mold to avoid damage. At this point, the part has extra material, called flash, around its edges from the injection process.

This flash needs to be trimmed to get the final shape and size. Trimming can be done by hand or with machines, depending on how detailed the part is. This step makes sure the part is the right size and free of flaws.

After trimming, the part is checked for quality to ensure it is accurate and smooth. This step ensures the parts meet high standards for industries like cars and airplanes. High pressure die casting makes parts that are precise and ready to use right away.

Advantages of High Pressure Die Casting

High Production Efficiency

High-pressure die casting is great for making many parts fast. The process is quick, as molten metal fills molds in seconds. Cooling also happens quickly, saving time. This speed helps meet large orders without losing quality.

It also reduces extra work after casting. The method is precise, so less machining is needed. This saves time and materials. Plus, the molds last a long time, lowering costs for each part over time.

Here’s why this process is so efficient:

| Feature | Benefit |

|---|---|

| Fast Production | Shorter times for making many parts quickly. |

| Detailed Shapes | Can create thin walls and complex designs. |

| Smooth Surfaces | Less need for extra finishing work. |

| Less Machining | Accurate casting reduces extra cutting or shaping. |

| Cost Savings | Long-lasting molds lower costs for big projects. |

Superior Dimensional Accuracy

This method makes parts that match exact measurements. High pressure pushes metal into every mold corner, ensuring accuracy. This is important for industries like cars and planes, where small errors can cause problems.

The process gives consistent results every time. Molds keep their shape through many uses, making all parts uniform. This reduces mistakes and avoids frequent changes during production.

Ability to Produce Complex Designs

High-pressure die casting is perfect for making detailed designs. It uses special techniques to ensure metal flows smoothly into tricky molds. For example, adjusting pressure and cooling time can reduce defects.

Simulation tools, like ProCAST software, help plan and test designs virtually. This ensures better results with fewer mistakes. These tools are especially useful for creating complex shapes.

With this method, you can make designs that are hard to achieve otherwise. Whether you need thin parts, sharp edges, or detailed patterns, this process delivers strong and precise results.

Cost-Effectiveness for Large-Scale Production

High pressure die casting saves money when making many parts. It is efficient and can produce thousands of identical pieces with little waste. Once a mold is ready, it can be reused many times. This lowers the cost of each part over time.

This process also reduces the need for extra work like machining. The molds are precise, so parts come out almost ready to use. This saves both time and materials. For big projects, this means lower labor costs and faster production.

The molds are also very strong. They are made from high-quality steel and can handle repeated use. This strength means fewer replacements are needed, which cuts costs even more.

Here’s why this method is cost-saving:

- Reusable molds: Strong molds last longer and save money.

- Minimal waste: Accurate casting uses less material.

- Reduced labor: Less finishing work saves time and money.

- High output: Fast production meets large orders quickly.

By using high pressure die casting, you get great results while keeping costs low.

Compatibility with Various Alloys

High pressure die casting works with many types of alloys. This makes it useful for different industries. Each alloy has special features, so you can pick the best one for your needs.

For example, aluminum alloys like A1350 and A380 are popular. They are strong and lightweight, making them great for high-pressure casting. The process also improves the metal’s structure, creating smaller grains that make the parts stronger and better.

Here’s a comparison of two common alloys used in high pressure die casting:

| Alloy Type | Pressure Range (kg/cm²) | Hardness | Yield Strength | Impact Strength | Microstructure Changes |

|---|---|---|---|---|---|

| A1350 | 350 – 1400 | Better | Better | Better | Smaller grains |

| A380 | 350 – 1400 | Better | Better | Better | Smaller grains |

This flexibility lets you create parts for many uses, like lightweight car parts or tough industrial tools. Choosing the right alloy ensures your parts perform well and meet high standards.

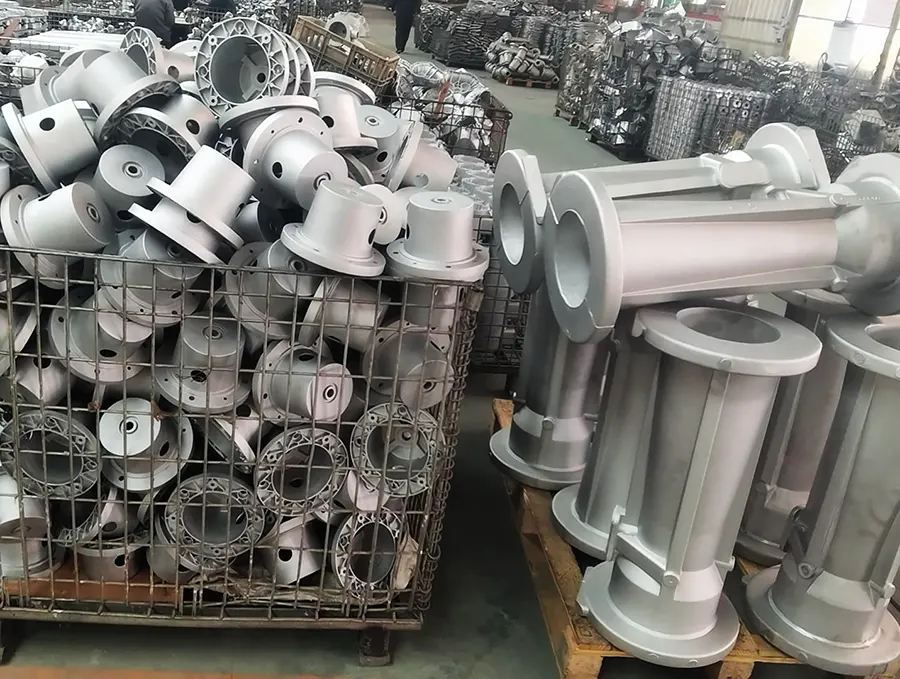

Common Uses of High Pressure Die Casting

Car Parts

High pressure die casting is important in making car parts. It helps create strong, light parts like engine blocks and transmission cases. This process supports the need for fuel-saving and electric cars.

A major car company used this method for engine parts. It helped them make precise parts, improving efficiency and cutting emissions.

The demand for die-cast car parts is growing fast. Some main benefits are:

- Lighter cars for better gas mileage.

- Strong parts that last a long time.

- Affordable production for making many parts.

Airplane Components

In airplanes, this method makes strong, light, and detailed parts. It is used for engine covers, gearboxes, and structural pieces.

| Feature | Benefit |

|---|---|

| Fast Production | Makes many parts quickly. |

| Saves Materials | Reduces waste, which is key for airplane needs. |

| Strong Materials | Creates parts that are light but very strong. |

| Complex Shapes | Can make tricky designs with tight measurements. |

| Smooth Surfaces | Gives great finishes, needing less extra work. |

These features make it a top choice for airplane makers. It ensures parts meet strict rules for safety and performance.

Electronics

Electronics makers use this method for light and strong parts. It is common in making cases for phones and laptops.

| Feature | Benefit |

|---|---|

| Saves Money | Makes many parts fast with little waste, cutting costs. |

| Quick Production | Lowers costs while keeping high quality. |

| Light Parts Needed | Helps meet the demand for thinner, lighter gadgets. |

As gadgets get smaller and smarter, this method helps keep up. It allows for detailed designs, making devices work well and look good.

Medical Equipment

High pressure die casting is important for making medical tools. This method creates strong and exact parts for healthcare needs. Using zinc alloys, it makes detailed designs with tight measurements, perfect for medical devices.

For example, small medical tools need thin walls to work better. Zinc alloys help make these thin walls strong and long-lasting. Zinc also blocks RFI/EMI, protecting electronics in medical devices. This keeps them working well, even with electromagnetic interference around.

Here are the main benefits of using high pressure die casting for medical tools:

- Precision and durability: Makes accurate and strong parts.

- Complex shapes: Helps create thin designs for easier use.

- Shielding capabilities: Protects electronics from interference.

This process helps make safe and high-quality medical tools that work well.

Industrial Machinery

High pressure die casting is very useful for industrial machines. It helps make detailed parts that are strong and consistent. This is important for heavy-duty jobs in industries like cars, planes, and equipment making.

New die casting technology now makes lighter parts without losing strength. For example, computer-aided design improves quality and reduces waste. This makes the process faster and better for the environment.

The demand for high pressure die casting is growing fast. In 2024, it was worth USD 42.9 billion and may reach USD 61.2 billion by 2030. This shows how industries need light, strong materials for better performance.

Key benefits of this process for industrial machines include:

- Precision and repeatability: Makes detailed parts with steady quality.

- Lightweight components: Improves performance and saves energy.

- Technological advancements: Boosts efficiency and cuts waste.

Using high pressure die casting helps meet modern industry needs and stay competitive.

High pressure die casting is important in today’s manufacturing world. It makes parts quickly, accurately, and with detailed designs. Industries like cars and airplanes depend on it for high-quality results.

Main Advantages:

- Accuracy creates detailed parts with smooth surfaces.

- Fast production helps make many parts quickly.

- Complex designs allow for tricky shapes and exact sizes.

| Feature | Explanation |

|---|---|

| Accuracy | Makes precise parts with great surface finishes. |

| Speed | Produces large amounts of parts quickly. |

| Uses in Industries | Common in cars, planes, and electronics. |

The need for better tools and detailed designs shows its value. Learn how this method can improve your production process.

FAQ

What is high-pressure die casting and how does it work?

High-pressure die casting is a manufacturing process where molten metal is injected into a steel mold at high speeds (30–100 m/s) and pressures (1,500–32,000 psi). This creates precise, strong, and complex parts with smooth surfaces, often with wall thicknesses as thin as 1 mm. Once the metal cools and solidifies, the part is ejected, trimmed, and ready for use.

What are the main advantages of high-pressure die casting?

Key benefits include high production efficiency, superior dimensional accuracy, ability to produce complex shapes, compatibility with multiple alloys, and cost-effectiveness for large-scale manufacturing. It also minimizes material waste and reduces post-processing requirements.

What is the difference between the hot chamber and cold chamber die casting methods?

The hot chamber process is ideal for low-melting-point metals like zinc and keeps metal molten between castings for faster production. The cold chamber process handles higher-melting-point metals like aluminum and magnesium, with molten metal poured into a separate chamber before injection—resulting in stronger, heat-resistant parts.

Which metals and alloys are commonly used in high-pressure die casting?

Common alloys include aluminum (e.g., A1350, A380), magnesium, and zinc alloys. Aluminum is lightweight and durable, zinc allows for fine detail and corrosion resistance, and magnesium offers strength with reduced weight. Each alloy is chosen based on the application’s performance needs.

What industries benefit most from high-pressure die casting?

Industries such as automotive, aerospace, electronics, medical equipment, and industrial machinery rely heavily on high-pressure die casting for lightweight, strong, and precise parts—ranging from engine blocks and gearbox housings to smartphone casings and surgical instruments.

How does high-pressure die casting achieve such high precision?

The combination of extreme injection pressure, rapid filling, and accurate mold design ensures that molten metal fills every detail of the mold cavity. This produces parts with tight tolerances, consistent quality, and smooth finishes that require minimal machining.

What types of parts are best suited for high-pressure die casting?

It is ideal for parts that require thin walls, complex geometries, sharp details, and high strength—such as automotive engine components, aerospace structural parts, electronic housings, heat sinks, and medical device casings.

How does high-pressure die casting reduce production costs?

The process allows molds to be reused for thousands of cycles, minimizes scrap through precise metal usage, reduces secondary machining, and enables mass production at high speeds—making it especially cost-effective for large-volume manufacturing.

What quality control measures are important in high-pressure die casting?

Mold temperature regulation, use of release agents, precision in metal injection speed, and post-casting inspections are critical. Advanced simulation tools like ProCAST help optimize mold design and reduce defects such as porosity, flash, or shrinkage.

How is high-pressure die casting evolving with new technologies?

Recent advancements include computer-aided design (CAD) for mold optimization, improved alloy formulations for strength and corrosion resistance, and automated casting systems that increase speed, precision, and environmental efficiency. These innovations are expanding its applications across industries.