CNC Machining Services forNew Zealand

Equip your project with quality components

TonzaMachining is a leading provider of CNC machining services, specializing in precision manufacturing and fabrication. With years of expertise and cutting-edge technology, we are dedicated to delivering top-quality products to meet the needs of our clients in various industries. Our team of skilled professionals is committed to providing exceptional service and exceeding customer expectations.

At TonzaMachining, we understand the importance of accuracy and efficiency in CNC machining services. That’s why we utilize state-of-the-art equipment and follow strict quality control measures to ensure that each project is completed with precision and consistency.

Whether you require prototyping, production runs, or custom parts, our team has the expertise to deliver superior results every time.

Type of CNC Machining Services for New Zealand

The topic selected is not provided.

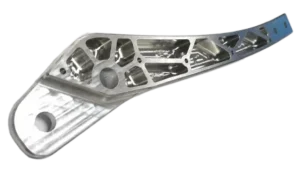

CNC Milling services

CNC Turnning services

5-Axis CNC Machining

Precision Machining Services

Capabilities of CNC Machining Services for New Zealand

Our CNC machines maintain ultra-precise measurements that manufactured with regulatory compliance in mind, maintaining precision across every unit.

Tolerances

±0.05mm

Refined engineering excellence to provide you with top-tier product performance.

Max part size

200 x 80 x 100 cm

Equipped with cutting-edge machinery, customer-centric approach in every project

Wall Thickness

0.75 mm

Years of practical expertise, skilled in managing intricate product designs.

Lead Time

< 10 days

Seamless communication across departments, and optimized workflow for speed and quality

Why Choose ours CNC Machining Services?

delivering exceptional results through experience, dedication, and strategic thinking.

working closely with clients to understand their unique needs and goals

featuring the latest technology and advanced machinery to ensure precision, efficiency.

delivering exceptional value without compromising on quality or precision.

CNC Machining Solutions for New Zealand

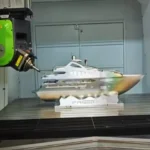

Our company specializes in providing customized manufacturing solutions to address the specific requirements of our clients. From rapid prototyping to bridge production and full-scale mass production, we are dedicated to delivering high-quality products that meet and exceed customer expectations.

Rapid prototyping | Bridge Production | Massive Production |

|---|---|---|

Smaller Tool Stock, More Axis | Big Tool Stock, More Axis | Bigger Tool Stock, Less Axis |

Predominantly standard fixtures. | A few custom-made fixtures. | Custom Made Fixture |

Highly precise with significant variance. | Highly precise with significant variance. | Accurate with slight variance. |

Very expensive per Unit | expensive per Unit | Low per unit |

LT: 1-4 business days | LT: 5-12 business days | Lead Time: 2-4 weeks |

Capability:1-50 pcs | Capability:51-10,000 pcs | Capability:Above 10,001 pcs |

Surface Finishes for New Zealand's Customer

Discover the perfect surface finish for your project with our selection of over 20 options. Whether you prioritize functionality or aesthetics, we have the solution for you. Enhance the look and performance of your space with our premium finishes.

Brushing

Sand Blast

Polishing

Tumbling

Anodizing

Painting

Black Oxide

Powder Coating

Electroplating

Alodine

Passivation

Electroless Plating

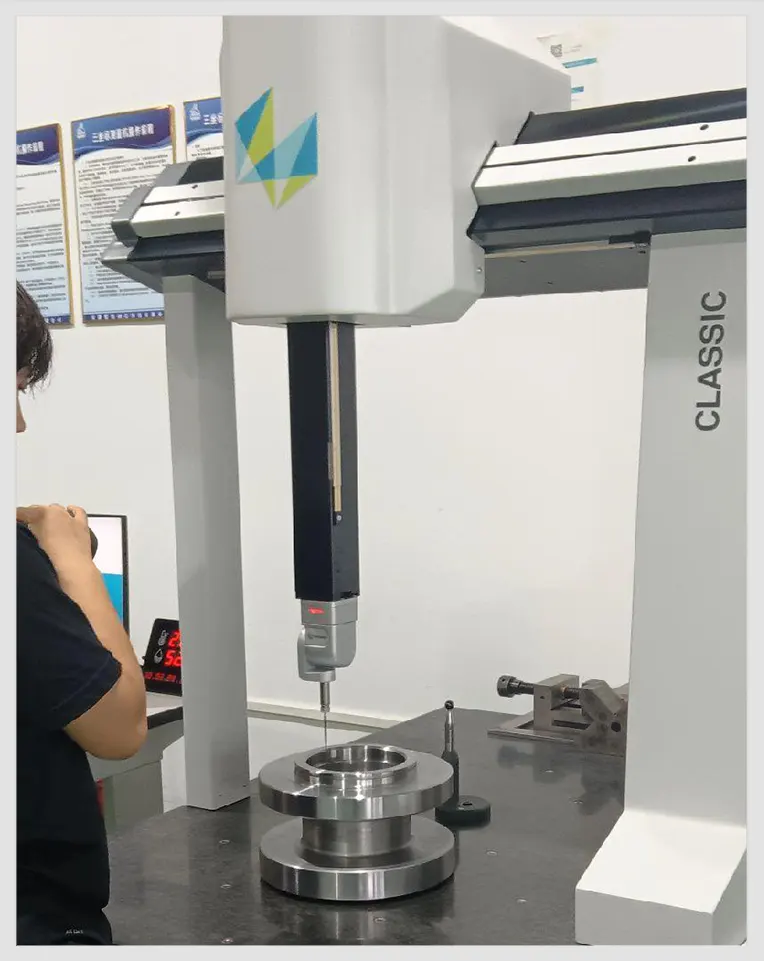

Certifications & Quality Standards

Our CNC machines deliver precision tolerances that meet industry standards, ensuring consistent accuracy and seamless component fit. With our advanced technology and skilled operators, we guarantee high-quality finished products that are durable and reliable. Trust us to provide top-notch machining services that exceed your expectations.

We follow industry standard ISO 2768 tolerances.

TonZa prides itself on having an ISO9001 certified quality management system, showcasing its dedication to upholding stringent quality control procedures in its production processes.

This commitment ensures that TonZa consistently delivers high-quality products to its customers, meeting and exceeding their expectations.

By adhering to internationally recognized standards for quality control, TonZa demonstrates a strong emphasis on product excellence and customer satisfaction in all aspects of its operations.

Click for more: Quality Control

Other Machining Capabilities

We offer a wide range of manufacturing services, including CNC machining, high-pressure die casting, sheet metal fabrication, injection molding, vacuum casting, 3D printing, and more for clients in the USA. Our skilled team ensures high-quality results and fast turnaround times to meet your production needs.

Injection Molding

Sheet Metal Fabrication

High Pressure Die Casting

Vaccum Casting

3D Printing

CNC Machining Services Locations Near Wellington, New Zealand

Our CNC machines guarantee precise tolerances that adhere to industry regulations, providing unparalleled accuracy and flawless component alignment. With our cutting-edge technology, we ensure consistent quality and seamless fit for all of your machining needs. Trust our expertise for unmatched precision.

TonZa is a leading provider of CNC Machining Services in New Zealand. With a strong reputation for precision and quality, TonZa offers a wide range of machining solutions to meet the needs of various industries. Our experienced team utilizes state-of-the-art technology and equipment to deliver efficient and cost-effective services to our customers. From prototype development to full-scale production, TonZa is dedicated to exceeding customer expectations and providing the highest level of craftsmanship. Trust TonZa for all your CNC machining needs in New Zealand, and experience the difference our expertise can make in your next project.

FAQ

CNC Machining Services in New Zealand FAQ