Hot runner systems are important in today’s injection molding. They make work faster, cut waste, and improve product quality. These systems can lower waste by up to 50%, helping the environment.

They also speed up production and give smoother product surfaces. Electric heating in these systems uses 30% less energy. If you want to save resources or make perfect products, this technology is accurate and dependable.

Understanding Hot Runner Systems

What Is a Hot Runner System?

A hot runner system is a tool used in injection molding. It keeps plastic melted as it moves into the mold. Unlike older systems, it doesn’t need cold runners, which waste material.

This technology has been used for over 50 years. It has changed how plastic parts are made.

Principle and structure

Hot runner (Hot Runner) technology is an important technology in the innovation of injection mold, it is the optimization and improvement of the cold runner technology of the injection mold, which belongs to the runnerless gel casting technology.

It is a runnerless condensate pouring technology. Heating rods or heating coils are added into the runner part of the injection mold.

These components continuously or adiabatically heat the mold’s pouring system. Temperature controllers accurately regulate the plastic’s temperature.

This keeps the plastic molten in the runners and sprues, preventing condensate formation in the pouring system. As a result, pressure loss during injection is reduced.

The melted plastic solution is then injected into the cavity of the mold by the injector nozzle.

In molds using hot runner technology, only the finished product is removed when the mold is opened to pick up the part. The solidified waste produced during the injection process does not need to be removed.

Instead, this waste can be recycled directly in the next injection process. It only needs to be heated to the required temperature before being injected into the cavity again.

According to the different heating methods, hot runner systems can be categorized into two types, i.e., adiabatic runner systems and heated runner systems.

Due to the many defects and technical immaturity of the molds using adiabatic runner system, not many manufacturers use this technology at present, while most of them use heating runner system.

At the same time, according to the different heat compensation methods, the heating runner system can be divided into two categories: endothermic and exothermic.

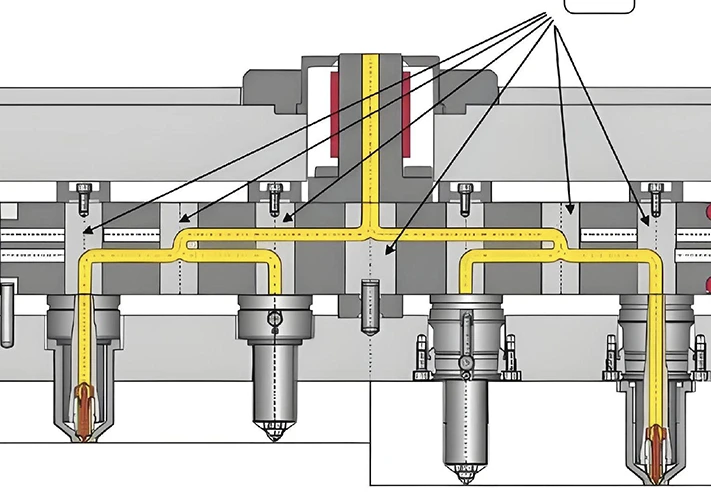

Composition Structure

Hot runner technology, as an innovation in mold making, is being used more and more widely. Its forms have also become increasingly diverse.

Generally, hot runner technology consists of several key parts:

-

The hot runner plate (manifold)

-

The nozzle

-

The heating element (heater)

-

The temperature controller

-

Auxiliary parts and other components

Part of the composition.

-

Plate

Its main task is to make the melt fed into the individual nozzles always maintain a constant temperature, in the process, to avoid the formation of pouring system condensate, reduce the pressure loss during injection.

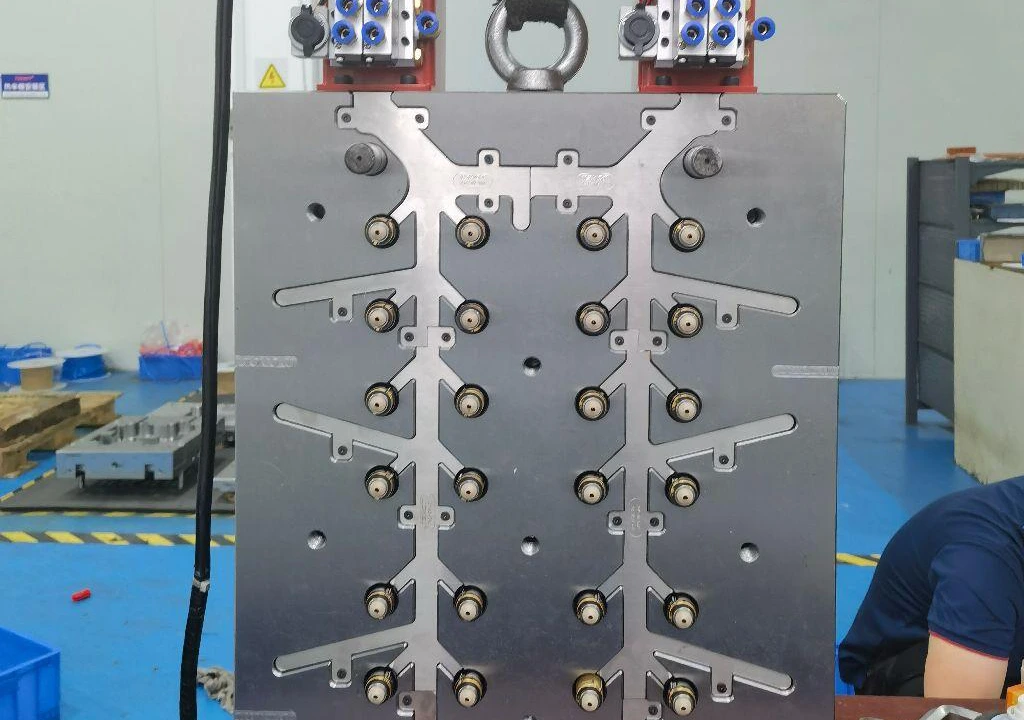

There are four types of hot runner plates we usually use: monogram, H-type, Y-type and X-type.

-

Hot nozzle

Its main role is to melt the plastic solution from the injector nozzle into the mold cavity.

The selection of the hot nozzle structure in a hot runner system mold injection process plays a very important role.

According to the different gate structures, the nozzle can generally be divided into three types: Open hot nozzle; Pointed hot nozzle; Needle valve hot nozzle.

-

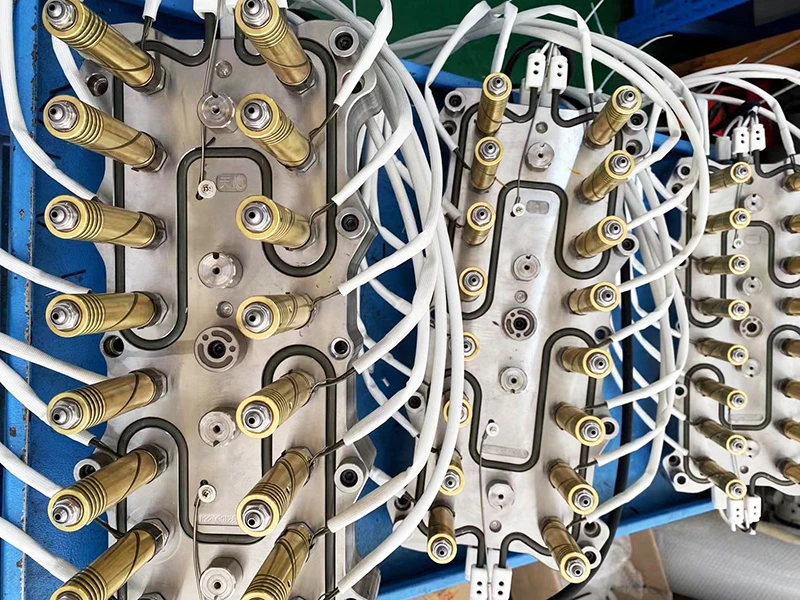

Heating element

In the injection molding process, its main role is to heat the hot runner plate or hot nozzle, so that the plastic in the runner and gate to maintain the molten state.

Heating elements usually include heating rods, thermocouples, heating rings, heating coils and so on.

The heating element is very important for the operation of the whole hot runner system.

-

Temperature controller

The task of the mold temperature controller is to accurately control the temperature of the plastic in the injection molding process.

According to the order of the bottom to the high-end, it can be divided into: through the bit, integral differential proportional control type, the new intelligent temperature controller three categories.

Mold temperature controller mainly includes cable, host, wiring male and female sockets, connectors and so on.

-

Other accessories

To complete a good injection molding process, but also need other accessories to work with the precision of the hot runner system and other auxiliary parts of the heat insulation block, junction box, support blocks and so on.

How Hot Runner Systems Work

Hot runner systems keep plastic melted during the molding process. The heated manifold spreads the melted plastic to the nozzles.

The nozzles then send it into the mold cavities. Temperature controllers help keep the heat steady. This stops the plastic from hardening too soon.

Gates manage how plastic flows into the mold. This ensures each cavity fills correctly. Cold runners are not needed, so there’s no extra waste to remove. This makes production faster, uses less material, and creates better parts.

Key Features

-

Advantages

Hot runner technology was first applied to mold production in the 1940s. After 70 years of development and improvement, it has advanced significantly.

With the continuous growth of the mold manufacturing industry, hot runner technology has been gradually promoted and widely applied.

It has achieved notable economic and environmental benefits. As a result, hot runner technology has become a key focus in the development of the injection molding industry.

Hot runner technology can be said to be the optimization and improvement of the cold runner technology of the injection mold, as a new injection molding technology, hot runner technology has the following advantages.

( 1) High product quality

In the process of injection molding using cold runner mold, due to the temperature, pressure and other imbalances, often make the plastic products appear shrinkage holes, fusion marks, flying edges and other defects.

Compared with cold runner technology in injection molds, hot runner technology keeps the plastic in the runner and gate molten at all times using a heating system. This reduces the pressure needed during injection.

The temperature controller precisely regulates the plastic’s temperature.

By balancing pressure and temperature, hot runner technology prevents condensate formation in the pouring system.

It can further reduce product shrinkage and plastic deformation. It also minimizes defects such as shrinkage holes, color differences, flying edges, and cracks.

These improvements enhance the surface quality of the products. Additionally, they increase the rigidity and strength of the products.

At the same time, hot runner technology avoids the repeated mixing and use of sprue material and reduces the scrap rate.

Therefore, hot runner technology has obvious technical advantages in the production process of transparent parts, thin-walled parts and other injection molded products that have higher requirements for product appearance quality.

( 2) Low energy consumption

One of the most significant features of hot runner is low energy consumption.

First of all, with hot runner molding technology, when opening the mold, only the finished product needs to be taken out. The solidified waste from the injection process does not need to be removed.

Instead, it is kept heated to the required temperature and directly injected into the cavity. This reduces sprue solidification and eliminates the need to clean the gate and other related processes.

Secondly, hot runner technology can basically avoid the gate material produced by ordinary runner, eliminating the runner waste, which can save raw materials and improve energy utilization.

According to statistics, using hot runner mold injection molding can save 30% to 50% of raw materials. Additionally, hot runner molding technology helps save raw materials and improves energy efficiency.

Hot runner molding technology reduces deformation, shrinkage, color differences, flash, cracks, and other defects in plastic products. This improvement enhances the appearance and overall quality of the product.

It can also eliminate secondary processes such as dyeing, trimming sprues, and spray painting. As a result, it reduces energy waste, lowers production costs, and minimizes raw material waste during mass production.

Therefore, hot runner molding technology for some back to the material more than the material used in the production of small products, energy saving effect is more prominent.

( 3) Short molding cycle

When using hot runner technology in molds, the solidified waste produced during injection can be directly recycled in the next injection process without cooling. The cooling cycle of the mold is only as long as the cooling time of the product.

This eliminates the process of removing the spout material, shortens the molding cycle, and improves economic efficiency.

At the same time, hot runner molding technology also eliminates the second process of dyeing, trimming sprues and spraying paint.

Compared with the molds applying ordinary runners, the molding cycle of the molds applying hot runners can generally be shortened by more than 30%.

Therefore, hot runner technology has the advantage of saving time and labor.

( 4) High degree of automation

Because hot runner applies automatic cut-off gate technology, the molding cycle is short and the molding process is continuous. Hot runner technology can precisely control the temperature of plastic through temperature controller, with high degree of automation.

Hot runner molding technology eliminates the need to remove the material handle during subsequent processing. Compared with ordinary runner technology, hot runner systems make it easier to realize production automation.

They can effectively reduce labor waste and improve production efficiency. This technology is also more conducive to the mass production of plastic parts.

At the same time, hot runner molding gate and runner design is more flexible, the choice of space is more free.

( 5) Wide range of application

With the development of the mold industry and the continuous optimization and improvement of hot runner, the scope of application of hot runner technology is also more and more extensive.

It is not only used for polyethylene, polypropylene and other melting temperature is wider than the processing of products, but also can be used for polyvinyl chloride, polyformaldehyde and other melting temperature is narrower than the processing of plastics.

Because hot runner technology can shorten the opening distance of the mold, therefore, it is more conducive to the production of molding longer products.

Hot runner technology can also effectively realize the production of multi-cavity plastic parts in one mold.

At the same time, the hot runner technology and other injection molding technology, can also expand the scope of application of hot runner technology.

In addition, hot runner technology also has the advantages of improving operation conditions, environmental protection and reducing power consumption.

hot runner system

-

Disadvantages

As a new mold innovation technology, hot runner technology, like other runner systems, has its own shortcomings and technical constraints.

Only by fully understanding these limitations can hot runner technology be further optimized and improved in production. This will enhance its practical value and increase its economic benefits..

The disadvantages of hot runner technology are mainly reflected in the following aspects.

( 1) Complexity of the mold structure

In the injection molding process, in order to make the plastic always maintain the molten state, the need for continuous heating of the mold’s casting system, which is a high demand for hot runner design, which causes the complexity of the mold structure.

And the cost cost of the mold using hot runner technology is very high, so it is difficult for those manufacturers who have little capital and weak technology to adopt the mold with hot runner technology.

( 2) Temperature control precision requirements

In order to avoid non-uniform filling of the plastic melt, hot runner technology requires zoned heating and precise control of the temperature of the plastic through multiple temperature controllers, so as to maintain a balanced temperature of the molten material.

At the same time, due to poor temperature control and other factors also tend to make the hot runner technology heating device is easily damaged, thus increasing the difficulty of maintenance.

( 3) Operator quality requirements

Compared with the use of cold runner molds, the use of hot runner technology mold operation process is more complex, more comprehensive, maintenance and repair technology requirements are higher.

At the same time, according to the different kinds of plastics, the hot runner technology molds also need to use different hot nozzles. Therefore, it requires personnel with specialized operating knowledge to operate.

In addition, hot runner injection technology has the following drawbacks: high start-up scrap, high raw material requirements, easy damage to heaters, and high cleanliness requirements for molding resins.

However, with the continuous development of hot runner injection technology, these difficulties and shortcomings are constantly being overcome and reduced. Hot runner molds will have great application and development prospects.

hot runner system

Development trend

As an innovative technology for injection molds, hot runner technology has many advantages, and its scope of use is becoming more and more extensive, representing one of the development directions of injection molds.

In recent years, with the development of the mold industry, as well as the improvement of the market requirements, hot runner technology is also in constant development and improvement, and its development trend is mainly reflected in the following aspects.

( 1) Miniaturization of components

The miniaturization of components is one of the main directions for the development of future injection molds, which can well realize the precision injection molding.

Hot runner molds shrink the nozzle, you can achieve a mold cavity or multiple gate filling, thus improving the efficiency.

From the 1990s, many companies have used the miniaturization of components, successfully developed a combination of compound nozzles or multi-spout nozzles.

( 2) Standardization of components

The structure of hot runner molds is complicated and the cost is high. The standardization of components can effectively improve the use cycle of components, reduce costs, and facilitate the maintenance of components.

The most important point is more conducive to the popularization and application of hot runner technology.

At the same time, you can use computer-aided technology to confirm the mold design program to improve the standardization of components.

( 3) Precision of temperature control

The quality of plastic parts is largely related to the temperature of the injection process, the key technology of hot runner mold injection molding is the control of the temperature of the runner and gate.

Therefore, various technologies such as heat pipe technology can be combined to improve the accuracy of the temperature control device, so that the heat of each part is more balanced, which can better improve the quality of plastic products.

( 4) Widening of use

As hot runner technology offers advantages such as resource conservation, improved production efficiency, and enhanced product quality, expanding its scope of use is the primary direction for its future development.

For this reason, combined with its current development status and other injection molding technologies, there is a need to develop new molding processes.

These include multi-color co-injection and stacked hot runner injection molding, among others. Such advancements aim to meet the requirements of a wider range of materials and enhance the practicality of hot runner technology.

FAQ

What is a hot runner system in injection molding?

A hot runner system is a specialized mold component that keeps plastic molten as it flows from the injection unit into the mold cavities. Unlike traditional cold runner systems, it eliminates solidified sprues and runners, reducing waste and improving production efficiency.

How does a hot runner system work?

Hot runner systems use heated manifolds and nozzles to maintain the melt temperature as plastic travels into the mold cavities. Temperature controllers ensure precise heat regulation, preventing premature solidification and ensuring uniform cavity filling for higher-quality parts.

What are the main components of a hot runner system?

A complete hot runner system typically includes the hot runner plate (manifold), hot nozzles, heating elements, and temperature controllers. Auxiliary parts such as insulation blocks, junction boxes, and support components ensure stable operation and mold performance.

What are the advantages of using hot runner technology?

Hot runner technology improves product surface quality, reduces cycle times by over 30%, cuts raw material waste by up to 50%, and enhances automation capabilities. It also supports complex part designs and multi-cavity molding, making it ideal for high-volume production.

How does hot runner technology reduce waste and save energy?

By keeping plastic molten in the runner and gate, hot runner systems eliminate solidified sprues and allow direct re-use of the melt. This not only saves raw materials but also lowers energy consumption by up to 30% compared to cold runner systems.

Are there any disadvantages to hot runner systems?

Yes. Hot runner molds are more complex and expensive to manufacture. They require precise temperature control, skilled operation, and higher maintenance standards. Initial s

What industries benefit most from hot runner injection molding?

Hot runner technology is widely used in automotive, medical devices, consumer electronics, packaging, and household goods manufacturing—especially for transparent parts, thin-walled products, and components with strict surface quality requirements.

What is the difference between adiabatic and heated runner systems?

Adiabatic runner systems rely on insulation to maintain plastic temperature, while heated runner systems use electric heating elements. Due to better performance and reliability, heated runner systems are more commonly used in modern injection molding.

How is hot runner technology evolving?

The latest trends include miniaturization of components for precision molding, standardization to reduce costs, advanced temperature control for higher product quality, and expanded use in multi-color co-injection and stacked mold applications.

Is a hot runner system worth the investment for my manufacturing process?

If your production involves high-volume runs, strict quality standards, or expensive resins, a hot runner system can significantly improve efficiency, product quality, and material savings. Although the initial cost is higher, the ROI can be substantial over time.