ensure cost-effective fabrication tailored to your needs.

Online Vacuum Casting Service

We offer expert vacuum casting services, delivering high-quality, precision-molded parts with smooth finishes, ideal for prototypes and low-volume production.

- Our in-house machine shop operates 24/7, ensuring quick turnaround times.

- Typical leading time 3 days.

What is Vacuum Casting?

We provide comprehensive Vacuum Casting services, utilizing various methods to accommodate diverse material needs and project specifications.

Vacuum casting is an advanced technique that utilizes polyurethane resins to produce highly accurate replicas of master patterns.

It begins with a meticulously crafted silicone mold, typically formed from a 3D-printed master. By casting under vacuum conditions, this method eliminates air bubbles, resulting in detailed, high-quality parts comparable to injection molding. Offering a faster and more cost-effective solution, vacuum casting is ideal for prototyping, small to medium production runs, and high-quality end-use components.

TonZa provides a wide selection of color options in our vacuum casting services, ensuring a perfect match for your design specifications and branding needs. Achieve vibrant, consistent colors that enhance both aesthetic appeal and product recognition.

Why Choose ours Vacuum Casting Service?

delivering exceptional results through experience, dedication, and strategic thinking.

working closely with clients to understand their unique needs and goals

featuring the latest technology and advanced machinery to ensure precision, efficiency.

leveraging cutting-edge technology to manufacture intricate components

delivering exceptional value without compromising on quality or precision.

ensuring fast, efficient, and reliable production without compromising quality.

Capabilities of Vacuum Casting Services

We provide top-quality Vacuum Casting services, delivering high-precision, finely finished parts at competitive prices.

reach ±0.05 mm

1.5mm~2.5mm

25 copies per mold

Color and texture can be customized

Vacuum Casting Materials

Ideal for prototyping, small to medium production runs, and high-quality end-use components, our vacuum casting solutions provide versatility and reliability for a wide range of applications.

| Name | Color | Temperature resistance | Feature |

|---|---|---|---|

| ABS-like | Naturally white and various multicolor options are available to suit your needs. | 40-50℃ | Good Hardness |

| Nylon-like | White | Resilient | |

| Nylon GF-like | Black | 120℃ | Good Strength |

| PC-like | translucent/transparent | 40-50℃ | Resilient |

| POM-like | Natural white and multiple color options are available upon request. | 40-50℃ | Good Hardness |

| TPU-like | Color can be adjusted as required | 100℃ | Shore Hardness40-90 |

| Silicone Rubber-like | Color can be adjusted as required | 100℃ | Shore Hardness40-90 |

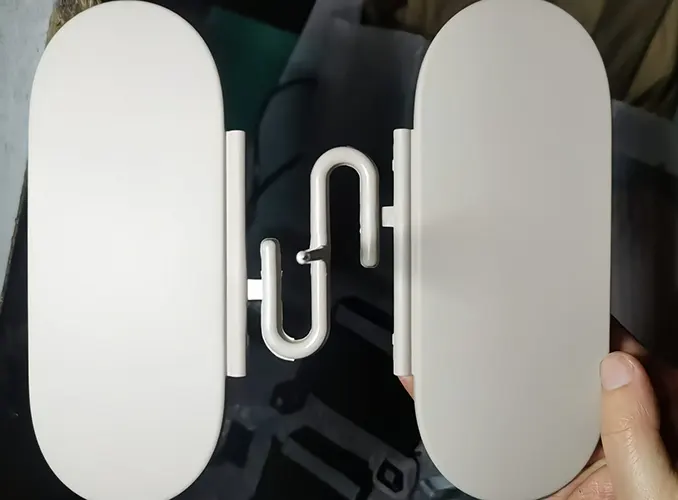

Process Work

We provide top-quality Vacuum Casting services, delivering high-precision, finely finished parts at competitive prices.

01

Create the master pattern

The initial step is to create the master pattern using a 3D printer or another manufacturing method. It should be made from a material capable of withstanding the heat and pressure involved in the silicone mold-making process.

02

Making Silicone Mold

Casting molds are typically made from liquid silicone resin, commonly known as RTV (room temperature vulcanizing) molds. Silicone rubber offers excellent chemical stability, self-releasing properties, and flexibility, resulting in minimal shrinkage and the accurate transfer of fine details from the master to the mold.

03

Casting Process

Carefully pour the mixed urethane into the mold, ensuring that air bubbles are minimized. Using a vacuum chamber can help eliminate trapped air, making the process more precise. This technique is why urethane casting is also known as vacuum casting

Advantages

Ideal for prototyping, small to medium production runs, and high-quality end-use components, our vacuum casting solutions provide versatility and reliability for a wide range of applications.

Applications

Sheet metal fabrication produces a variety of parts and components, each tailored to meet specific functional and aesthetic requirements.

Automotive

- Custom dashboard components and instrument panels

- Engine covers and fluid reservoirs

- Gaskets and seals

Aerospace

- Aerodynamic prototypes for testing

- Custom grips and handles for cockpit controls

- Seals and grommets

- Lightweight ducting and ventilation parts

Electronic

- Keypads, buttons, and switch covers

- Connectors and casings for cables

- Insulating components

- Enclosures for electronic devices and circuit boards

Industrial Machinery

- Custom housing for control systems

- Covers and guards for machinery

- Functional parts for testing and validation

- Handle grips and ergonomic components

Medical

- Custom medical device enclosures

- Surgical instrument handles and grips

- Anatomical models for training and testing

- Prototype parts for medical imaging devices

Military and Defense

- Tactical equipment housings and enclosures

- Communication device casings

- Prototypes for field-testing defense gear

- Seals and shock-absorbing components

FAQ

We provide SPI surface finishes for injection-molded parts. Our experts are ready to help you select the ideal finish for your project.

We offer a variety of materials, including polyurethane resins that mimic ABS, PP, PC, rubber, and other engineering plastics. These materials can be selected based on specific mechanical properties and aesthetic requirements.

Vacuum casting provides excellent detail, accuracy, and surface finish, closely resembling injection-molded parts. While injection molding is better for large-scale production, vacuum casting is faster and more cost-effective for low to medium volumes.

- High-quality surface finish

- Bubble-free and precise parts

- Faster and more affordable than injection molding for small batches

- Wide material and color options

- Ideal for prototyping and small production runs

Lead times vary depending on the complexity and quantity of parts, but most vacuum casting projects can be completed within 5 to 7 days.

Yes, we offer a range of color options, including naturally white, solid colors, and transparent finishes, to match your design and branding requirements.

Vacuum casting is widely used in industries such as automotive, medical, consumer electronics, and industrial equipment for rapid prototyping, functional testing, and small-scale production.

A single silicone mold can typically produce 25 to 35 high-quality parts before it begins to degrade, depending on the material and complexity of the design.

Blog

Welcome to our blog, where we share insights into various manufacturing processes.