Can a CNC machine file be converted and printed on a 3D printer?

Can a CNC Machine File be Converted and Printed on a 3D Printer?

In the world of manufacturing, precision and accuracy are paramount. With the advancements in technology, engineers are constantly looking for ways to streamline their processes and expand their capabilities.

One question that often arises is whether a CNC machine file can be converted and printed on a 3D printer.

This article takes a deep dive into the topic, offering practical insights tailored for engineers with a manufacturing background.

Understanding CNC Machining and 3D Printing

CNC machining and 3D printing are two popular manufacturing processes that enable engineers to create intricate designs with high precision.

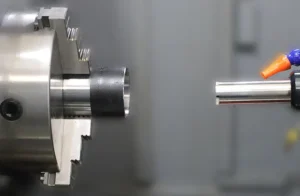

CNC machining involves using computer-controlled machines to remove material from a solid block, resulting in the desired shape.

On the other hand, 3D printing, also known as additive manufacturing, builds objects layer by layer using materials such as plastic, metal, or resin.

Converting a CNC Machine File for 3D Printing

While CNC machining and 3D printing have distinct differences, it is possible to convert a CNC machine file for 3D printing with the right tools and techniques.

The first step is to export the CNC machine file in a compatible format, such as STL (Standard Tessellation Language) or OBJ (Wavefront Object).

These file formats can then be imported into a slicing software, which will generate the toolpath for the 3D printer.

Considerations for Conversion

Before converting a CNC machine file for 3D printing, there are several key considerations to keep in mind.

One of the main factors is the design complexity and geometry of the CNC file. Not all designs are suitable for direct conversion, as some may require modifications to ensure proper printing on a 3D printer.

Additionally, material compatibility is crucial when converting a CNC machine file for 3D printing.

While CNC machining typically uses metals and rigid plastics, 3D printing offers a wider range of materials, including flexible plastics, resins, and even metal powders.

It is essential to select a material that is compatible with both the design and the printing process.

Adjusting Parameters for 3D Printing

When converting a CNC machine file for 3D printing, it may be necessary to adjust certain parameters to optimize the printing process.

For example, the layer height, infill density, and print speed can impact the quality and strength of the final object.

By fine-tuning these parameters, engineers can ensure a successful transition from CNC machining to 3D printing.

Benefits of Converting CNC Files for 3D Printing

There are several benefits to converting CNC machine files for 3D printing.

One advantage is the ability to create complex geometries and intricate designs that may be challenging or impossible to produce with traditional CNC machining methods.

3D printing also offers faster prototyping and lower costs for small batch production, making it a cost-effective solution for many engineering projects.

Challenges and Limitations

Despite the advantages of converting CNC files for 3D printing, there are also challenges and limitations to consider.

One common issue is the resolution and surface finish of 3D printed parts, which may not meet the same standards as those produced by CNC machining.

Engineers must carefully evaluate the requirements of their project to determine if 3D printing is a suitable alternative.

Conclusion

In conclusion, the conversion of CNC machine files for 3D printing offers a unique opportunity for engineers to explore new possibilities and expand their manufacturing capabilities.

By understanding the process of conversion, considering key factors, and adjusting parameters as needed, engineers can leverage the benefits of both CNC machining and 3D printing to achieve optimal results.

While challenges and limitations exist, the potential for innovation and efficiency makes the conversion of CNC files for 3D printing a worthwhile endeavor for the engineer group with a manufacturing background.