Painting services for you

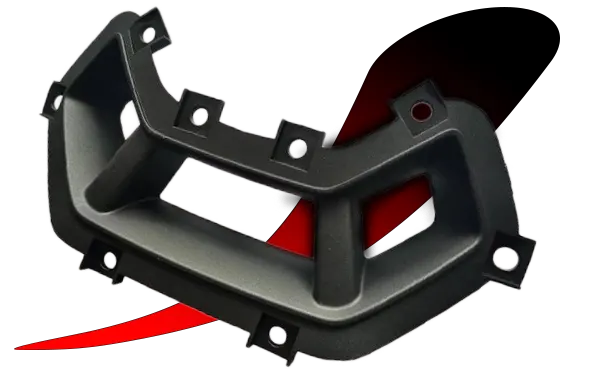

With a focus on quality, our Painting services provide parts that achieve high-quality surface directly, meet the demands of customers.

What is Painting in Surface Treatment?

Surface treatment painting is a crucial process in industrial applications that involves applying a protective or decorative coating to a surface using various techniques.

Painting as a surface treatment method serves multiple purposes, including enhancing the aesthetic appeal of a product, protecting it from corrosion, improving durability, and providing resistance to environmental factors such as moisture, chemicals, and UV radiation.

The process of painting involves the application of a liquid paint or powder coating onto a substrate, which is then cured to form a hard finish.

Different painting methods, such as brush painting, spray painting, and powder coating, are utilized based on the specific requirements of the application.

Surface treatment painting not only adds value to the appearance and functionality of a product but also plays a vital role in extending its lifespan and performance.

Main Feature

Optimize your designs for manufacturability with our expert painting capability, ensuring the best results for your product.

Advantages

- Corrosion protection – creates a barrier against moisture, oxygen, and chemicals that cause rust and degradation.

- Aesthetic appeal – offers a wide range of colors, gloss levels, and textures to improve appearance.

- Cost-effective – generally less expensive than plating or powder coating.

- Versatility – can be applied to different types of metals and complex shapes.

- Repairable – scratches, chips, or worn areas can be easily touched up with new paint.

- Customization – supports branding, labeling, and functional markings.

Disadvantages

- Lower durability – compared to powder coating or anodizing, paint is more prone to chipping, scratching, and peeling.

- Limited wear resistance – not suitable for high-friction or abrasive environments.

- Requires surface preparation – poor adhesion occurs without cleaning, priming, or sanding.

- Environmental concerns – solvent-based paints release VOCs (volatile organic compounds), affecting sustainability and safety.

- Maintenance needed – painted surfaces may require periodic recoating to maintain protection.

Design Considerations for Painting Parts

Our CNC equipment offer tight tolerances that conform to sector standards, ensuring reliable precision and seamless component integration.

Surface Preparation

Material Selection

Geometry and Accessibility

Uniform Coating Thickness

Adhesion Features

Masking Requirements

Durability Needs

Repair and Maintenance

Environmental & Process Constraints

FAQ about Painting

For a clearer understanding of what we offer, here are FAQs on our Painting process.

Painting is a coating process that applies liquid or spray-applied paint onto metal surfaces to enhance corrosion resistance, improve appearance, and extend the material’s lifespan.

Painting forms a protective barrier that shields metals from moisture, oxygen, and chemicals, preventing rust and surface degradation in industrial and consumer applications.

The key advantages include corrosion protection, cost-effectiveness, wide color and finish options, ease of application, and the ability to touch up damaged areas.

Painted surfaces can chip, scratch, or peel more easily than powder coating or anodizing, and often require more frequent maintenance or recoating.

The durability depends on the paint type, application quality, and environmental conditions. With proper preparation and maintenance, painted metal surfaces can last several years before requiring refinishing.

Proper cleaning, degreasing, sanding, or priming is essential to ensure strong paint adhesion and prevent premature coating failure.

Painting is more cost-effective and easier to repair, while powder coating provides a thicker, more durable, and wear-resistant finish that requires specialized equipment.

Traditional solvent-based paints release VOCs, which can impact air quality. However, water-based and low-VOC paints are more sustainable options for eco-friendly surface finishing.

Yes, unlike some surface treatments, painting is easily repairable. Damaged areas can be sanded, primed, and repainted without needing to redo the entire surface.

Painting is widely applied in automotive, construction, appliances, machinery, and consumer goods manufacturing, where both protection and aesthetics are required.