Electroplating services for you

With a focus on quality, our Electroplating services provide parts that achieve high-quality surface directly, meet the demands of customers.

What is Electroplating in Surface Treatment?

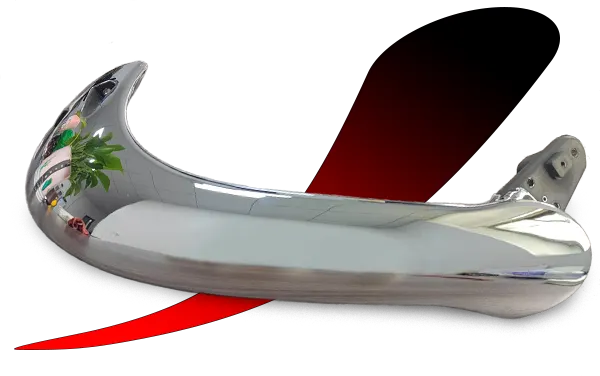

Electroplating is a surface treatment used to improve the look, performance, and durability of metal and non-metal parts.It works by using electric current to deposit a thin layer of metal—such as copper, nickel, silver, gold, or chromium—onto a surface.

This process improves corrosion resistance, wear resistance, conductivity, and also provides decorative finishes.

Electroplating is widely used in automotive, electronics, aerospace, jewelry, and household appliances where both function and appearance matter.

The process includes surface preparation, cleaning, activation, plating, rinsing, and drying. By carefully controlling factors like current, temperature, pH, and time, manufacturers can achieve the desired coating quality.

However, electroplating also involves toxic chemicals and heavy metals, which create environmental concerns. Modern operations focus on sustainability and waste management to reduce its impact.

Main Feature

Eletroplating involves toxic chemicals, careful waste management and sustainable practices are essential to minimize environmental impact.

Advantages

- Corrosion resistance – protects metals from rust and oxidation.

- Enhanced appearance – provides a smooth, shiny, and decorative finish.

- Improved hardness and wear resistance – strengthens surfaces against scratches and friction.

- Better conductivity – useful for electrical and electronic components.

- Restoration – can repair and restore worn or damaged parts.

- Versatility – applicable to many metals and industries.

Disadvantages

- High cost – requires specialized equipment and materials.

- Environmental impact – uses toxic chemicals and heavy metals.

- Maintenance – coatings may wear off and require re-plating.

- Thickness limits – not suitable for very thick or heavy-duty coatings.

- Complex process – needs careful control of parameters for quality results.

- Energy consumption – relies on continuous electric current.

Design Considerations for Electroplating Parts

Our CNC systems offer exact tolerances that meet industry norms, guaranteeing reliable precision and perfect component fit.

Material Compatibility

Surface Preparation

Geometry & Accessibility

Uniform Coating Thickness

Masking Areas

Size & Weight Limits

Tolerance Control

Stress & Adhesion

Aesthetic Needs

FAQ about Electroplating

To help you better understand our Electroplating capabilities, we’ve answered the most frequently asked questions.

Frequently Asked Questions

All-in-One questions for Customer

Key benefits include corrosion protection, improved durability, enhanced conductivity, controlled coating thickness, and attractive appearance suitable for high-value applications like jewelry and electronics.

Electroplating involves toxic chemicals, requires precise process control, consumes high energy, and may result in coatings that wear over time, requiring maintenance or re-plating.

Common plating metals include nickel for wear resistance, chromium for hardness, silver and gold for conductivity and aesthetics, and copper for undercoats and conductivity.

Electroplating is essential in automotive, aerospace, electronics, jewelry, medical devices, and household appliances where both performance and aesthetics are important.

The coating thickness typically ranges from a few microns to several dozen microns, depending on the application and required protection.

Since electroplating adds material to the surface, designers must account for coating thickness in tight-tolerance dimensions to avoid fit issues.

Traditional electroplating uses heavy metals and toxic chemicals, which pose environmental risks. However, modern processes focus on sustainable practices, waste treatment, and eco-friendly alternatives.

Yes, worn or damaged coatings can often be stripped and re-plated, making electroplating suitable for restoring parts without replacing them entirely.