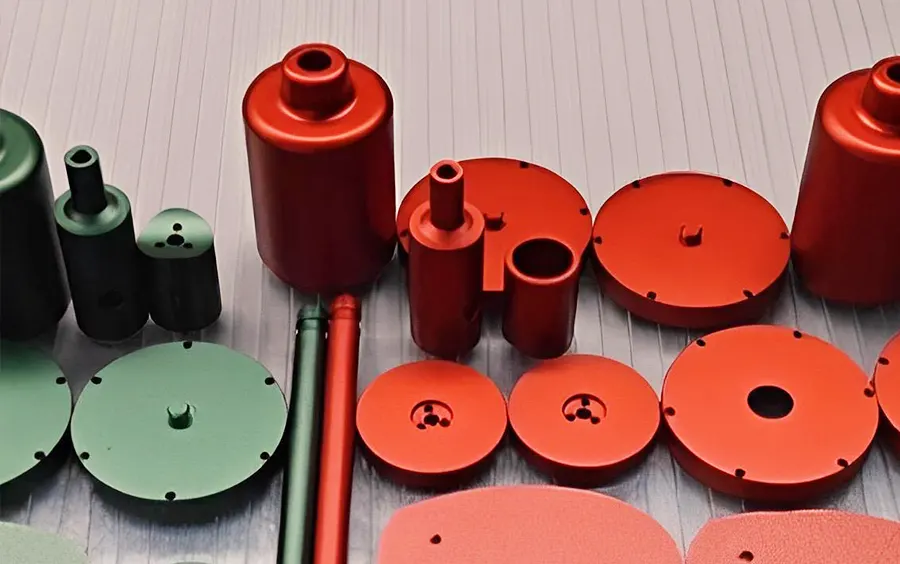

Anodizing services for you

With a focus on quality, our Anodizing services provide parts that achieve high-quality surface directly, meet the demands of customers.

What is Anodizing in Surface Treatment?

Anodizing in surface treatment is an electrochemical process used mainly for aluminum and its alloys to create a durable, protective oxide layer on the surface of the metal.

Instead of coating the surface with paint or plating, anodizing actually converts the outer layer of the metal into aluminum oxide. This oxide layer is hard, corrosion-resistant, and wear-resistant, while also providing an excellent base for coloring and additional finishes.

Key Points about Anodizing in Surface Treatment:

- Protection: Increases resistance to corrosion, wear, and weathering.

- Aesthetics: Allows for vibrant coloring and decorative finishes.

- Durability: Harder than natural aluminum oxide, extending part life.

- Applications: Commonly used in aerospace, automotive, electronics, architecture, and consumer products (like smartphones and kitchenware).

Main Feature

Optimize your designs for manufacturability with our expert guidelines and feedback, ensuring the best results for your product.

Advantages

- Excellent Corrosion Resistance – The anodized oxide layer protects aluminum from oxidation, moisture, and chemicals.

- Increased Surface Hardness – Anodizing produces a hard surface that is more wear- and scratch-resistant than raw aluminum.

- Improved Adhesion – The porous oxide layer provides a strong base for dyes, paints, or adhesives.

- Aesthetic Variety – Anodized aluminum can be dyed in different colors for decorative purposes.

- Environmentally Friendly – Unlike plating, anodizing does not use heavy metals; the process is relatively eco-friendly.

- Electrical Insulation – The oxide layer is non-conductive, making anodized aluminum suitable for electronic applications.

Disadvantages

- Limited to Certain Metals – Mainly works with aluminum and its alloys; less effective on other metals.

- Thickness Control – The oxide layer is thin compared to coatings like powder coating or plating; not ideal for heavy-duty protection.

- Brittleness of the Layer – While hard, the anodized surface can be brittle and prone to cracking under impact or bending.

- Color Fading – Dyed anodized layers can fade over time if exposed to UV light.

- Cost for Small Runs – Anodizing requires specialized equipment and chemical baths, making it less cost-effective for low-volume production.

- Dimensional Changes – The process slightly alters part dimensions, which must be considered in precision machining.

Design Considerations for Anodizing Parts

Our CNC equipment offer precision limits that meet sector standards, securing reliable exactness and flawless component integration.

Allow for Dimensional Change

Consider Sharp Edges and Corners

Uniform Thickness Challenges

Masking Requirements

Threaded Features

Color Consistency

Surface Finish Before Anodizing

Part Size and Rack Contact Points

Sealing Requirement

FAQ about Anodizing

Find clear answers to the most common questions about our Anodizing solutions.

Frequently Asked Questions

All-in-One questions for Customer

What are the main advantages of anodizing?

Anodizing provides excellent corrosion resistance, surface hardness, electrical insulation, and enhanced wear resistance. It also allows aluminum parts to be dyed in a variety of colors, improving both function and aesthetics without adding an external coating that could chip or peel.

What are the limitations of anodizing?

Anodizing is limited mainly to aluminum and requires tight process control. The oxide layer is relatively thin compared to coatings like powder coating, and color consistency may vary between alloy batches. Additionally, anodized layers can be brittle under heavy impact.

How does anodizing improve corrosion resistance?

Anodizing forms a dense aluminum oxide barrier that seals the surface against moisture, salts, and chemicals. When sealed properly, anodized aluminum resists weathering and marine environments, significantly extending the life of the part.

Can anodized parts be colored?

Yes. The porous anodized surface allows for dye absorption, enabling a wide range of colors such as black, red, blue, or gold. After coloring, the anodized layer is sealed to lock in the dye and improve fade resistance.

What industries use anodizing in surface treatment?

Anodizing is widely used in aerospace, automotive, electronics, architecture, and consumer products. From aircraft parts and car components to smartphones and kitchenware, anodized aluminum provides a durable, corrosion-resistant, and visually appealing finish.

How does anodizing affect part dimensions?

Anodizing slightly changes part dimensions because the oxide layer grows both into the surface and outward. Roughly 50% penetrates into the aluminum, and 50% builds outward. Engineers must account for this in tight-tolerance designs.

What is the difference between Type I, Type II, and Type III anodizing?

Type I: Chromic acid anodizing, thin and corrosion-resistant.

Type II: Sulfuric acid anodizing, thicker, dye-absorbing, and common in decorative finishes.

Type III: Hardcoat anodizing, very thick and wear-resistant, used in aerospace and industrial applications.

How do I choose the right anodizing process for my parts?

The right anodizing process depends on application requirements, part material, and desired finish. Decorative products often use Type II anodizing with coloring, while aerospace or heavy-duty components may require Type III hard anodizing for maximum durability. Consulting a surface treatment expert ensures the best choice.