Are STL files Commonly Used for CNC Routers?

Are STL files commonly used for CNC routers?

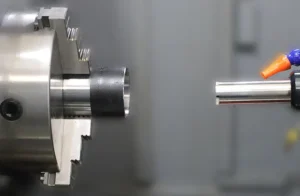

The rise of CNC routers has revolutionized manufacturing by making production faster, more accurate, and more efficient. Behind every CNC process is a digital file that directs the machine’s actions.

One of the most widely used formats in CNC routing is the STL file. We’ll explore how STL files are used in CNC machining and outline both their benefits and challenges.

Introduction to STL files

STL (Stereolithography) is a file format that is widely used in 3D printing and CNC machining.

It represents a 3D model as a series of interconnected triangles, known as a mesh. Each triangle is defined by its vertices and the normal vector to the surface it represents.

This simple and efficient representation makes STL files ideal for CNC routers, as they can easily interpret the geometry and generate toolpaths to machine the part.

Benefits of using STL files for CNC routers

There are several advantages to using STL files in CNC routing:

- Compatibility: STL files are supported by most CAD/CAM software packages, making them a versatile choice for sharing and transferring 3D models.

- Accuracy: The triangle mesh representation in STL files ensures that the geometry is accurately preserved when translated into toolpaths for machining.

- Efficiency: STL files are relatively small in size compared to other 3D model formats, which can help reduce processing time and memory usage during CNC machining.

- Customization: CNC routers can easily manipulate and modify STL files to optimize toolpaths and achieve the desired surface finish on the part.

Limitations of using STL files for CNC routers

While STL files offer many benefits for CNC routing, there are also some limitations to consider:

- Resolution: The resolution of an STL file is determined by the number of triangles used to represent the 3D model. A lower resolution can result in loss of detail and accuracy in the machined part.

- Complexity: Some complex geometries may be challenging to represent accurately in an STL file, leading to errors or imperfections in the machined part.

- Surface quality: Due to the polygonal nature of STL files, achieving a smooth surface finish on the machined part may require additional post-processing steps.

Best practices for using STL files in CNC routing

To maximize the benefits of using STL files in CNC routing, it is important to follow these best practices:

- Ensure that the STL file is watertight and free of errors before generating toolpaths for machining.

- Optimize the resolution of the STL file to balance detail and processing speed during CNC machining.

- Use support structures and finishing passes to improve surface quality and dimensional accuracy of the machined part.

- Regularly update and maintain the CAD/CAM software to ensure compatibility and functionality with STL files.

Conclusion

In conclusion, STL files are commonly used for CNC routers due to their compatibility, accuracy, efficiency, and customization capabilities.

While there are limitations to using STL files, following best practices can help mitigate these challenges and ensure successful CNC machining.

By understanding the strengths and weaknesses of STL files, engineers in the manufacturing industry can leverage this file format to optimize their CNC routing processes and achieve high-quality results.