Will a scratch on a CNC laser lens affect cutting performance?

Introduction

In the world of manufacturing, precision is key. CNC laser machines are a crucial tool in ensuring high-quality cuts and efficient production processes. However, even minor damages such as scratches on the lens of a CNC laser machine can potentially impact its cutting performance.

Understanding CNC Laser Cutting

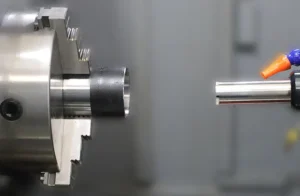

CNC laser cutting is a versatile and efficient method used in modern manufacturing processes. It involves using a high-powered laser beam to cut through various materials with high precision and accuracy.

The lens of a CNC laser machine plays a vital role in focusing the laser beam to ensure a clean and precise cut. Any damage to the lens can have a direct impact on the cutting performance of the machine.

Potential Effects of a Scratch on a CNC Laser Lens

Even a small scratch on the lens of a CNC laser machine can disrupt the focusing of the laser beam, leading to inconsistent cutting depths and inaccurate cuts.

The scratch can cause the laser beam to scatter or diffract, resulting in a loss of cutting power and reduced efficiency. In some cases, a scratch on the lens may also lead to overheating of the lens, further compromising its performance.

Impact on Cutting Quality

The presence of a scratch on the lens of a CNC laser machine can significantly impact the quality of the cuts produced.

The laser beam may not be able to focus properly on the material, leading to jagged edges, rough surfaces, and overall poor cut quality.

This can result in wastage of materials and increased production costs, as well as potential damage to the machine itself.

Reduced Cutting Speed

A scratch on the lens can also affect the cutting speed of a CNC laser machine. The machine may need to slow down to compensate for the loss of cutting power caused by the scratch.

This can lead to longer processing times, reduced productivity, and delays in production schedules. Ultimately, a scratch on the lens can have a direct impact on the overall efficiency of the manufacturing process.

Preventive Measures

Preventing scratches on the lens of a CNC laser machine is crucial to maintaining its cutting performance. Regular maintenance and cleaning of the lens can help prevent scratches from occurring.

Using protective covers or shields when not in use can also help reduce the risk of damage. Additionally, establishing clear protocols for handling and storing the machine can further minimize the chances of scratches on the lens.

Conclusion

In conclusion, a scratch on the lens of a CNC laser machine can have significant implications on its cutting performance. It can lead to reduced cutting quality, slower cutting speeds, and overall inefficiencies in the manufacturing process.

By understanding the impact of a scratch on the lens and taking preventive measures to avoid damage, manufacturers can ensure that their CNC laser machines continue to operate at optimal levels and produce high-quality cuts consistently.

1 thought on “Will a scratch on a CNC laser lens affect cutting performance?”

Machinists and makers alike will dig this.