Is it possible to cut aluminum with a CNC machine?

The Possibility of Cutting Aluminum with a CNC Machine

When it comes to manufacturing and engineering processes, precision is key. One of the most common tools used in modern production facilities is the CNC machine, which stands for Computer Numerical Control.

These machines are equipped with cutting-edge technology that enables them to perform a wide range of tasks, from milling and drilling to shaping and cutting materials like metal, plastic, and wood.

But can a CNC machine effectively cut aluminum?

We will explore the possibilities and challenges of using CNC machines to cut aluminum and provide insights for engineers with a manufacturing background.

Understanding Aluminum as a Material

Aluminum is a popular material in manufacturing due to its unique properties. It is lightweight, durable, corrosion-resistant, and easily recyclable, making it a versatile choice for a wide range of applications.

However, aluminum also poses challenges when it comes to machining. It is a softer metal compared to steel, which means that it is more prone to deformation and damage during cutting processes.

Moreover, aluminum has a tendency to generate a built-up edge on cutting tools, leading to poor surface finish and tool wear.

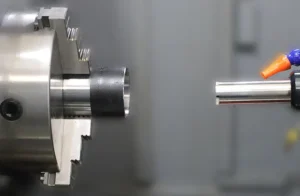

The Role of CNC Machines in Aluminum Cutting

CNC machines have revolutionized the way manufacturers approach cutting processes.

These machines are equipped with computer-controlled systems that can execute precise movements and cuts with remarkable accuracy and repeatability.

When it comes to cutting aluminum, CNC machines offer several advantages:

- High precision: CNC machines can perform intricate cuts and shapes on aluminum with high accuracy, ensuring consistent results.

- Efficiency: CNC machines can operate at high speeds, reducing production time and increasing productivity.

- Versatility: CNC machines can be programmed to perform a wide range of cutting operations on aluminum, from simple drilling to complex profiling.

Challenges of Cutting Aluminum with CNC Machines

While CNC machines offer numerous benefits for cutting aluminum, they also present some challenges that engineers need to be aware of:

- Tool wear: Aluminum is a soft material that can cause rapid wear and tear on cutting tools, leading to decreased tool life and increased costs.

- Chip control: The unique properties of aluminum, such as its tendency to form long, stringy chips, can pose challenges for chip evacuation and control during cutting processes.

- Heat generation: Cutting aluminum can generate a significant amount of heat due to its low melting point, which can affect tool life and surface finish.

Tips for Efficient Aluminum Cutting with CNC Machines

To overcome the challenges of cutting aluminum with CNC machines, engineers can implement the following tips and best practices:

- Use the right cutting tools: Select cutting tools that are specifically designed for aluminum cutting, such as carbide or high-speed steel tools.

- Optimize cutting parameters: Adjust cutting speeds, feeds, and depths of cut to minimize heat generation and maximize tool life.

- Implement proper chip control: Use chip breakers, coolant, or air blasts to ensure efficient chip evacuation and prevent chip accumulation.

- Monitor tool wear: Regularly inspect cutting tools for signs of wear and damage, and replace them as needed to maintain cutting quality.

Conclusion

In conclusion, cutting aluminum with a CNC machine is not only possible but also highly effective when done correctly.

By understanding the unique properties of aluminum, leveraging the capabilities of CNC machines, and implementing best practices for aluminum cutting, engineers can achieve high precision, efficiency, and quality in their manufacturing processes.

With the right knowledge and tools, cutting aluminum with CNC machines can open up a world of possibilities for creating complex and intricate aluminum components for a wide range of industries.