With the manufacturing industry’s increasing demand for product precision, CNC metal cutting machining has become a core process in modern production.

The accuracy of CNC metal cutting machining is not only related to the quality of the product, but also directly affects the production efficiency and manufacturing costs.

However, during the CNC metal cutting machining process, various factors such as cutting force, tool wear, and cutting heat can easily disrupt machining accuracy, leading to the accumulation of errors.

Therefore, improving the accuracy of CNC metal cutting machining has become a key task in the development of the manufacturing industry.

Error Types and Precision Impact Parameters

• Types of Machining Errors

(1) Machine Tool Geometric Error.

Originating from the deviation in the design, manufacture, and assembly of the machine structure, such as guideway straightness error and spindle radial runout.

(2) Tool Error.

Including tool manufacturing accuracy, clamping errors, and process wear, which directly affect cutting quality.

(3) Thermal Deformation Error.

Cutting process of machine tools, tools, and workpieces due to temperature changes resulting in thermal expansion or contraction, resulting in size and shape errors.

(4) Machining Dynamics Error.

With cutting vibration, machine tool rigidity or clamping force is insufficient, making it easy to trigger dynamic errors.

(5) Internal Stress Error.

The release of internal stress in the material will lead to deformation of the workpiece, which further reduces machining accuracy.

• Influence Parameters of Machining Accuracy

During the CNC metal cutting machining process, several key process parameters significantly impact machining accuracy, as outlined below.

(1) Cutting Speed.

A cutting speed that is either too high or too low may lead to poor surface quality or excessive tool wear, which in turn affects accuracy.

(2) Feed Rate.

Feed speed directly affects the machining surface quality and tool load. Feeding too quickly may cause vibration, which reduces machining accuracy.

(3) Cutting depth.

Excessive depth of cut will increase the cutting force, resulting in workpiece deformation or thermal distortion, which can affect machining accuracy.

(4) Tool Performance.

The geometry, sharpness, and material selection of the tool will affect the stability and accuracy of the cutting process.

The service life of the tool and its wear state also have a significant impact on machining accuracy.

A worn tool may lead to uneven cutting, which in turn generates dimensional deviation and increases surface roughness.

Parameter Optimization Methods

• Application of Optimization Algorithm

In CNC metal cutting machining, particle swarm optimization (PSO) is widely used for optimizing cutting parameters due to its simplicity of calculation and rapid convergence.

PSO algorithm searches for the optimal solution by simulating the process of particles moving randomly in the search space.

The basic formulas are as follows:

𝑣𝑖(𝑡+1) = w𝑣𝑖(𝑡) + c1α[Spbest – 𝑥𝑖(𝑡)] + c2β[Spbest – 𝑥𝑖(𝑡)] (1)

𝑥𝑖(𝑡+1) = 𝑥𝑖(𝑡) + 𝑣𝑖 (𝑡+1) (2)

where: 𝑣𝑖(𝑡) is the velocity of particle 𝑖.

𝑥𝑖(𝑡) is the position of the particle.

Spbest and Sgbest are the historical optimal position and global optimal position of particle 𝑖, respectively.

c1 and c2 are the acceleration constants.

w is the inertia weight.

α and β are random numbers.

Through continuous iteration, the PSO algorithm can effectively optimize parameters such as cutting speed, feed rate, and depth of cut, thereby improving machining accuracy and productivity.

• Machining Model Optimization

The optimization method based on the machining model requires engineers to establish physical models that describe the cutting force, temperature field, and deformation.

These models are typically based on theories of cutting mechanics, heat conduction, and material rheology.

The model parameters are fitted to experimental data to ensure the model’s accuracy.

Optimization is performed using these machining models to minimize variables such as machining errors, cutting forces, and cutting temperatures.

Engineers utilize machining models to predict the impact of various cutting parameters on machining accuracy.

They then apply optimization algorithms—such as genetic algorithms or particle swarm algorithms—to find the parameter combinations that deliver the best machining accuracy.

Through multiple iterations and simulation verification, the parameter tuning of the machining process is achieved, thereby improving the overall accuracy and efficiency of cutting machining.

• Computer-Aided Optimization

Computer-aided optimization predicts the impact of different machining parameters on machining accuracy and efficiency.

Engineers achieve this by establishing a mathematical model related to the machining process and using computer software to simulate and analyze the process.

Engineers utilize optimization algorithms, such as particle swarm optimization, genetic algorithms, and simulated annealing algorithms, to optimize the objective function in the model.

These algorithms help identify the optimal combination of parameters that maximizes processing efficiency, improves accuracy, and reduces both energy consumption and costs.

For example, in automotive parts machining, engineers used the particle swarm optimization algorithm to optimize cutting parameters.

This optimization resulted in a 12% improvement in machining accuracy, an 18% reduction in machining time, and a 15% increase in the service life of the cutting tool.

Computer-aided optimization can automatically adjust processing parameters and enable real-time monitoring.

It utilizes real-time data feedback to dynamically optimize parameters dynamically, ensuring the machining process remains in an optimal state at all times.

Accuracy Improvement Strategy

• Reasonable Setup of Machining Route

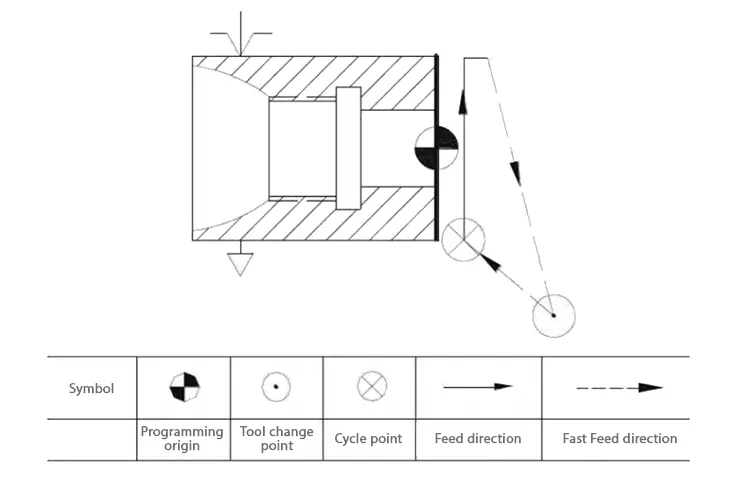

In CNC metal cutting processing, reasonable setting of the machining route is the key to improving machining accuracy and efficiency. CNC cutting route is shown in Figure 1.

(1) Analyze the parts and confirm the requirements.

Analyze the geometric structure of the part and processing requirements to determine the key surface, datum position, tolerance control points, and other special processing needs.

(2) Planning machining route.

Determine the priority machining surfaces and parts, such as datum surfaces and positioning holes.

According to the “easy to process part of the priority, difficult to process part of the back” principle, to determine the machining sequence.

(3) Division of processing stages.

Rough machining is primarily used to remove allowances, while finishing ensures dimensional accuracy and surface quality.

The processing method is adjusted according to the material characteristics to ensure a smooth transition.

(4) Optimize the path design.

Avoid frequent tool changes and empty strokes to optimize the smoothness of movement. Adopt arc transition or spiral path design to reduce tool impact and vibration.

Set up a reasonable route for entering and exiting the tool to ensure the continuity and stability of the tool movement.

(5) Set cutting parameters.

According to the performance of the machine tool and tool characteristics, set the cutting speed, feed rate, depth of cut, and other key parameters.

Optimize the combination of parameters with practical tests and experience to ensure efficient processing.

(6) Simulation verification and adjustment.

Simulate the machining path using computer-aided design/computer-aided manufacturing software to identify and resolve interference or collision problems.

Then, optimize the machining route and parameter settings according to the simulation results.

(7) Production monitoring and real-time adjustment.

Dynamically adjust the machining path and parameters in the machining process with the monitoring data to improve the reasonable path and production efficiency.

(8) Summarize and improve.

Summarize the experience and problems in the machining process, and provide optimization suggestions for subsequent parts processing.

• Scientific Use of Cutting Fluid

» Selection of Special Cutting Fluid

Cutting fluids are mainly categorized into two types: water-based cutting fluids and oil-based cutting fluids.

Water-based cutting fluids offer excellent cooling performance and are well-suited for high-speed cutting and low-load processing.

Oil-based cutting fluids provide excellent lubrication performance, making them suitable for heavy loads and low-speed cutting operations.

For example, in the high-speed cutting process, select a cutting fluid with excellent cooling properties to reduce the cutting temperature effectively.

In heavy-duty cutting conditions, the cutting fluid should be selected for its good lubricating properties to reduce friction and wear, thereby improving cutting efficiency.

Different processing materials have different cutting fluid requirements.

For example, aluminum alloy processing utilizes water-based cutting fluids, which offer excellent cooling and lubrication properties.

Stainless steel processing with oil-based cutting fluid, featuring good antioxidant and anti-rust properties.

During actual processing, staff should select the appropriate type of cutting fluid based on the specific processing needs.

For example, when precision machining, selecting a high-performance cutting fluid can enhance the surface quality and dimensional accuracy.

» Circulation and Purification of Cutting Fluid

In CNC metal cutting processing, installing a cutting fluid circulation system can ensure uninterrupted flow of cutting fluid during processing.

The circulation system comprises pumps, pipes, filters, and cooling devices to maintain the cleanliness of the cutting fluid and stabilize the temperature.

The cutting fluid can be evenly distributed throughout the cutting zone via the circulation system, playing a dual role of cooling and lubrication.

The cutting fluid circulation system utilizes high-efficiency filtration devices, including bag filters, paper tape filters, and magnetic filters.

These devices effectively remove debris, metal powder, and other impurities from the cutting fluid.

By doing so, they prevent impurities from re-entering the cutting zone, which helps maintain machining accuracy and extend the service life of cutting tools.

Therefore, based on the frequency of use and the type of materials being processed, develop a reasonable cleaning cycle.

Regular inspection and cleaning of the filtering device are essential to ensure its proper operation.

• Optimize Cutting Dosage

» Scientifically Formulate Cutting Amount.

Scientific development of cutting dosage is essential to improve the precision and efficiency of CNC metal cutting processing.

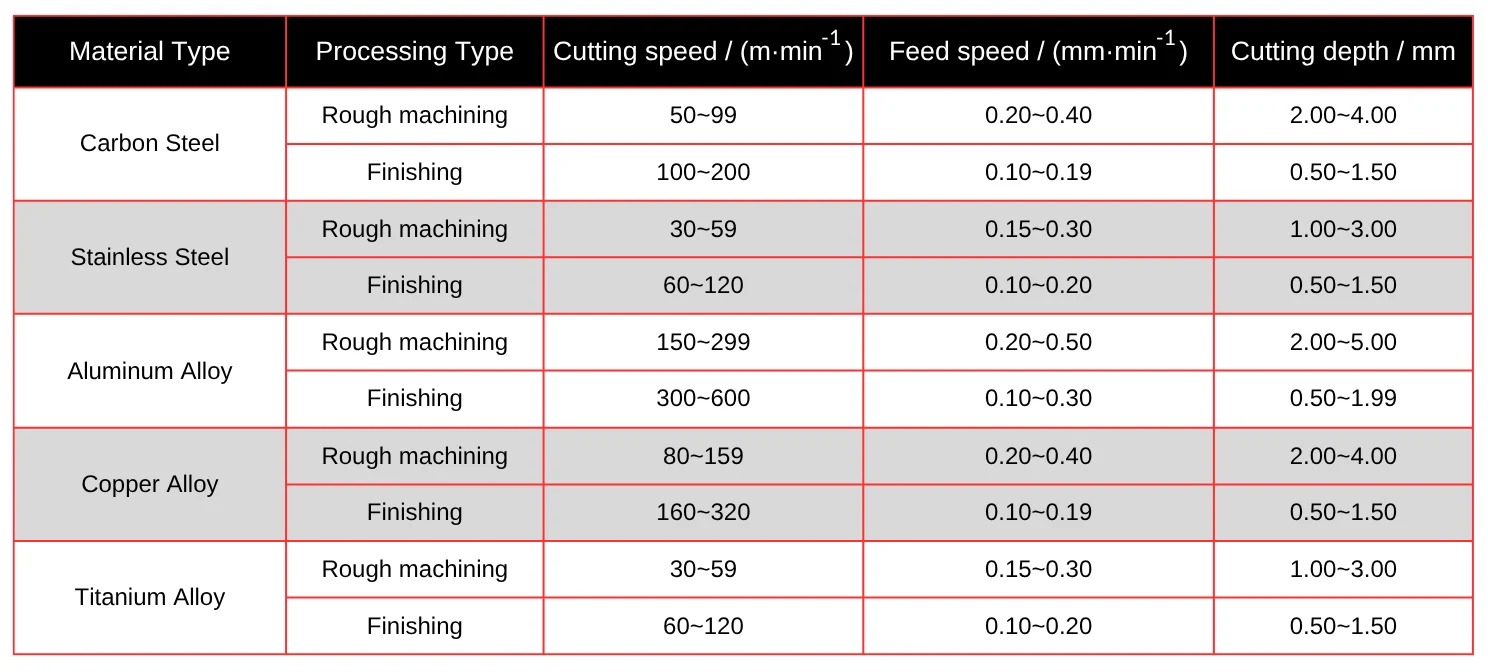

According to work practice, reasonable cutting dosage is shown in Table 1.

(1)Adjust the cutting speed based on the material’s hardness and thermal conductivity.

For example, when roughing carbon steel, operators typically use a cutting speed of 50 to 100 m/min.

For stainless steel, the roughing speed usually ranges from 30 to 60 m/min.

In contrast, operators can increase the cutting speed for aluminum alloy to 150 to 300 m/min during roughing.

This is because aluminum has lower hardness and higher thermal conductivity.

This differential selection can effectively reduce tool wear and improve the cutting efficiency of the tool.

(2) Combine the tool performance and surface quality requirements to set the feed rate.

During the roughing stage, operators can select a higher feed rate to remove excess material more quickly.

For example, the recommended feed per revolution for aluminum roughing ranges from 0.2 to 0.5 mm/r.

During the finishing stage, they need to reduce the feed rate to improve surface quality.

For instance, when finishing stainless steel, the feed per revolution typically ranges from 0.1 to 0.2 mm/r. This helps ensure the surface remains flat and smooth.

(3) According to the machining efficiency and machine tool capacity, set the depth of cut.

In roughing, operators typically select a larger depth of cut to enhance efficiency. For example, when roughing copper alloys, the cutting depth usually is 2 to 4 mm.

In contrast, during the finishing process, they select a smaller depth of cut—usually between 0.5 and 1.5 mm.

This helps reduce surface deformation of the workpiece, minimize the heat-affected zone, and ensure machining accuracy.

» Treat roughing and finishing differently

In CNC metal cutting machining, the process objectives of roughing and finishing differ, so it is necessary to adopt a differentiated cutting volume strategy to meet the requirements of both machining efficiency and accuracy simultaneously.

The primary objective of roughing is to rapidly remove excess material from the workpiece, reduce machining time, and establish a uniform machining allowance for subsequent finishing.

Finishing, on the other hand, focuses on improving dimensional accuracy and surface quality, emphasizing stability and meticulousness.

In the roughing stage, to efficiently remove excess material, it is recommended to select a greater depth of cut and feed rate.

For example, the depth of cut for rough machining of aluminum ranges from 2 to 5 mm, and the feed rate is 0.2 to 0.5 mm/min), and such parameter settings help to give full play to the cutting capacity of the machine tool and cutting tool.

However, the cutting speed should be moderate (150 to 300 m/min), so as not to overheat the tool too quickly or increase wear.

In the fine machining stage, to improve the flatness and accuracy of the workpiece’s surface, a smaller depth of cut and feed rate should be used.

For example, the depth of cut for finishing copper alloys is 0.5 to 1.5 mm, and the feed rate is 0.1 to 0.2 mm/rev.

The cutting speed can be increased appropriately (160-320 m/min) to ensure a smooth machined surface and reduce surface residual stress.

Conclusion

The improvement of CNC metal cutting machining accuracy involves a variety of factors, and accurately identifying and reducing the source of machining error is the key to improving machining accuracy.

The application of optimization algorithms, optimization of processing model parameters, and computer-aided optimization technology can effectively improve processing accuracy and productivity.

Reasonable setup of machining routes, scientific use of cutting fluid, and optimization of cutting dosage are also necessary means to improve machining accuracy.

In the future, intelligent technology and automation control systems will continue to develop.

These advancements will improve the precision of CNC metal cutting machining and drive the manufacturing industry toward higher accuracy and greater efficiency.

FAQ

Why is CNC metal cutting machining critical to modern manufacturing?

CNC metal cutting machining is essential because it directly affects product precision, production efficiency, and manufacturing costs. It has become a core process in response to rising industry demands for high-quality, accurate parts.

What are the main types of machining errors in CNC cutting?

Machining errors include machine tool geometric error, tool error, thermal deformation, machining dynamics error, and internal stress error. Each type influences the final precision of the machined part.

How do cutting parameters affect machining accuracy?

Cutting speed, feed rate, and cutting depth significantly impact surface quality, tool wear, and workpiece deformation. Optimizing these parameters is key to maintaining machining accuracy.

What role do optimization algorithms play in CNC machining?

Algorithms like Particle Swarm Optimization (PSO), Genetic Algorithms, and Simulated Annealing help engineers find the best combination of cutting parameters. This enhances efficiency, reduces costs, and improves accuracy.

How does computer-aided optimization improve CNC machining?

By simulating machining processes through mathematical models, computer-aided optimization allows real-time monitoring and automatic adjustment of parameters, ensuring consistent and optimal machining conditions.

What is machining model optimization, and how does it work?

Machining model optimization involves building physical models of cutting forces, temperature, and deformation. Engineers fit these models to experimental data and use them to fine-tune machining parameters for better accuracy.

How can the cutting route affect machining accuracy?

A well-planned cutting route minimizes tool changes, avoids unnecessary movements, and ensures smoother tool paths. This reduces tool wear and vibration, leading to higher machining accuracy.

What’s the importance of using appropriate cutting fluids?

Cutting fluids cool, lubricate, and protect tools during machining. Choosing the right type (water-based or oil-based) and maintaining its purity with filters helps improve surface quality and extend tool life.

Why should roughing and finishing use different cutting settings?

Roughing focuses on quickly removing material, requiring higher feed rates and depth of cut. Finishing emphasizes precision and smooth surfaces, using lower feed rates and shallower cuts to achieve better dimensional accuracy.

What future trends will influence CNC metal cutting accuracy?

Intelligent technologies and automation control systems will continue to advance. These developments will further enhance machining precision, efficiency, and enable adaptive, self-optimizing CNC operations.