Before starting a new titanium alloy milling process, selecting the right tool is crucial to improve productivity and reduce costs. However, due to the alloy's difficult machinability, significant time and labor are often spent on test cuts.

To address this, a method is proposed that uses torque signals collected during initial test cuts to evaluate and predict tool life. This approach enables quick, side-by-side comparisons between different tools to select the most suitable one.

While average torque can reflect tool wear, its value varies across tools due to differences in camber angles and coatings. To overcome this, the method extracts high-frequency components from the torque signal—minimizing parameter influence—and applies a recurrent neural network to map these features to tool life over time.

Experiments show the method accurately predicts tool life after just a few test cuts, reducing testing time by two-thirds. It works across tools with varying geometries and coatings, helping identify the optimal tool for titanium alloy machining.Editor

Lu Haotian, Ji Chenyu, Zhang Shengwei, Shen Bin

Introduction

Titanium alloy is widely used in various fields because of its high strength, good corrosion resistance, heat resistance and other characteristics, especially in the aircraft engine compressor parts, rockets, missiles and high-speed aircraft structural parts are highly favored;

However, titanium alloy cutting due to its high material hardness cutting difficulties, and prone to sticky knife phenomenon and other reasons, so that before carrying out the new titanium alloy milling process, always spend more time for the selection of machining tools, adjusting machining parameters; pick out a tool adapted to the process can effectively improve production efficiency and reduce processing costs.

Therefore, quickly assessing whether a tool is suitable for the process has become the key to reduce labor and time costs in the early stage. The most commonly used indicator to judge whether a tool is adapted to the machining process is the tool life, in the case of face milling, the life is equivalent to the volume of the tool that can be cut on the blank before the depth of wear of the rear face to half of the depth of cut.

In order to avoid interruption of the cutting process during online monitoring of tool life, signals related to the tool machining state, such as cutting force, vibration, acoustic emission, current and power, are usually captured and used to determine the status of the tool online.

Literature [1] extracts features from the vibration signals generated by the milling cutter during machining, uses decision trees to classify the features related to the tool state, and compares the advantages and disadvantages of the J48 tree family classifiers, logistic model trees, and random forests in the performance of milling cutter condition judgment;

Literature [2] proposes a full-stage regression model modeling method for tool wear based on the AdaBoost integration algorithm, and establishes a regression model for tool wear state identification, which is capable of identifying the tool wear state through the data collected during machining;

Literature [3] will be a series of time-frequency domain indexes of a variety of signals collected during machining for feature screening, and after obtaining feature vectors with high correlation, the wear value is predicted by using a sparse self-coder, and then the remaining life of the tool is predicted by a deep feed-forward network;

Literature [4] through the spindle current signal extraction of clutter, access to the processing parameters are not related to the characterization of tool wear features, and the improvement of LeNet so that it can predict the wear of a single machining convolutional neural network, can be realized under complex machining conditions of the milling cutter wear state of the on-line accurate identification for the remaining life of the online prediction of the foundation;

Literature [5] uses continuous wavelet transform (CWT) and BSS separation technology to extract signal features, and uses high-dimensional spatial nonlinear regression to establish a model of the signal to the remaining service life of the milling cutter tool, which can effectively reflect the trend of the tool performance decline.

There are few studies on tool wear as well as life prediction at home and abroad, and the core idea of various methods is to establish the relationship from signal features to wear (life).

They are usually aimed at the prediction of wear under a fixed machining environment, or the prediction of the performance of a tool under different cutting parameters, etc. Few studies have been conducted on the performance of different tools under the same machining conditions of the tool.

In the early stage of process establishment, it is often necessary to judge different tools, and it is important to obtain the predicted life of different tools required for tool selection.

In order to identify the expected life of different milling tools under the same working conditions, a new method is proposed.

The method extracts signal features that have little correlation with the machining tool and reflect the wear state of the tool or abnormal machining vibration, and designs an RNN model to map the relationship between them and tool life.

The rest of the paper consists of the following sections:

Section 2 describes the method of extracting features from the torque signal and the model of the GRU recurrent neural network.

Section 3 describes the experimental setup and construction of the dataset.

Section 4 discusses and compares the results and Section 5 concludes.

Tool optimization method based on milling tool life prediction

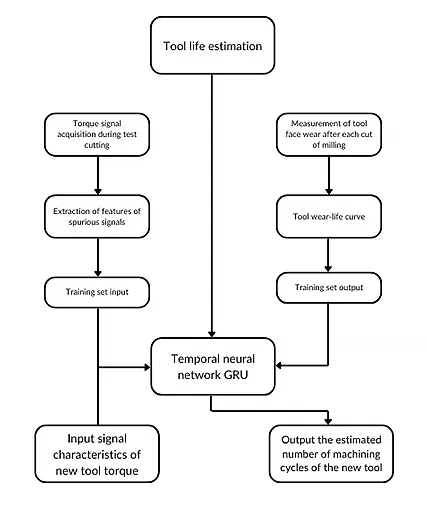

The method innovatively fits the features on the intrinsic frequency of the toolbar to the tool life using RNN.

Firstly, a class of tools of different brands with different tool parameters are selected for a particular milling process.

After that, test cutting experiments are conducted on the tool to collect torque signals during the cutting process and measure the back face wear of the tool after each machining;

Following this, the features of the torque signal of a single machining are extracted, and the sequence of features of the tool during the continuous machining to reach the damage process is used as the input to the RNN;

Finally, the life index obtained from the wear of the tool throughout its life cycle through the wear life curve is used as the output;

The two sets of data are used to train the RNN to obtain the prediction model, and the method flow is shown in Figure 1.

-

Torque high-frequency signal extraction reflecting wear features

In the milling process, the cutting torque increases with the wear of the cutting edge and the increase of tool face friction, and many scholars have done a lot of research on the relationship between the two.

The research results show that the change in the size of the cutting torque can reflect the wear state of the tool.

Therefore the cutting torque contains characteristic information that reflects the wear state of the milling cutter.

Literature [6] in the study of dynamic force spectrum analysis found that there is an obvious characteristic peak in the high frequency band away from the machining frequency, which is close to the intrinsic frequency of the toolpost, independent of the chip formation frequency, and in the same wear stage of different tools, the characteristic frequency basically remains unchanged.

It is further found in the literature [6] that the amplitude of the eigenfrequency signal increases monotonically with tool wear and decreases sharply when it enters into rapid wear or tool fracture, so the high-frequency component of the torque contains characteristic information about the change of cutting edge shape and the wear of the tool back face.

The low-frequency component of the torque signal is related not only to tool wear, but also to machining and tool parameters, and characterizes the cutting torque required by the milling cutter to strip the metal material from the workpiece surface.

The initial value and variation of the low-frequency component of the torque are very different for tools with different parameters for machining.

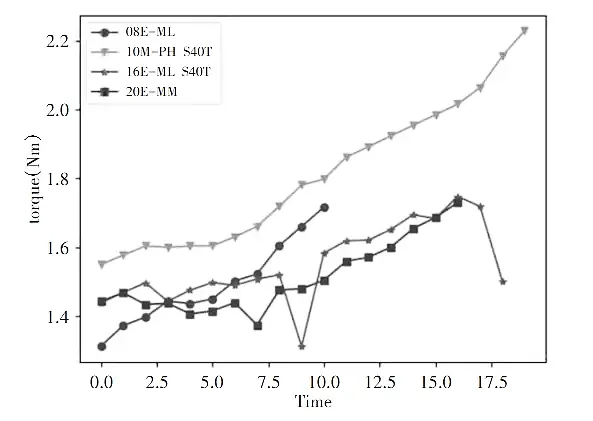

The variation of the amplitude of the low frequency component of torque with the number of machining operations during the life cycle of four milling cutters with different fillet radii, camber angles and materials is shown in Fig. 2.

From the comparison, it can be seen that the torque of different tools is inconsistent for the same wear state, so it is difficult to represent the wear state of different tools by the low-frequency component of the torque signal, and there may be a misjudgment if the low-frequency component of the torque signal is used to identify the wear state of different tools.

In summary, it is not possible to directly use the low-frequency component of the torque signal to identify tool life under the conditions of identifying different tool life.

The high-frequency component, on the other hand, is mainly affected by factors such as edge shape change, rear face wear and abnormal system vibration, which has little correlation with the parameters of the tool itself, but also contains relevant information that can reflect the wear of the milling cutter.

In the actual signal acquisition, it was found that not only the peaks appeared near the intrinsic frequency of the toolholder, but also the corresponding peaks appeared at its octave frequency, therefore, when using the torque high-frequency signal to identify the wear state of different milling cutters to predict the life of the cutter, the amplitude of the frequency and the subsequent multiple octave frequency were selected as the characteristics.

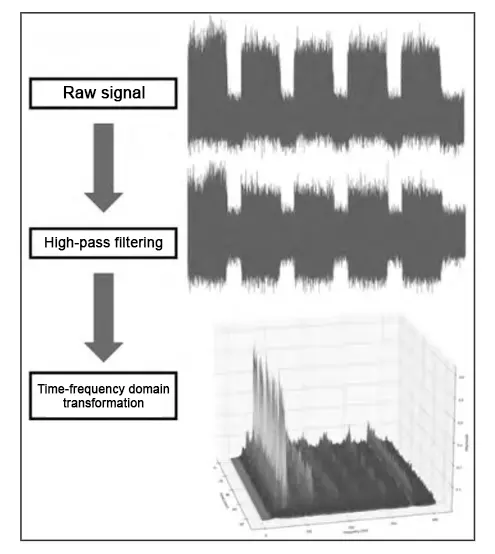

The specific method of extracting the features of the torque high-frequency signal is divided into six steps, as shown in Fig. 2.

(1) Collect the cutting torque signal of the milling cutter during the test cutting process through the spike shank, and record the wear of the back face of the tool after each machining.

(2) The signal from one machining passes through a high-pass filter to remove the components of the signal near the machining frequency.

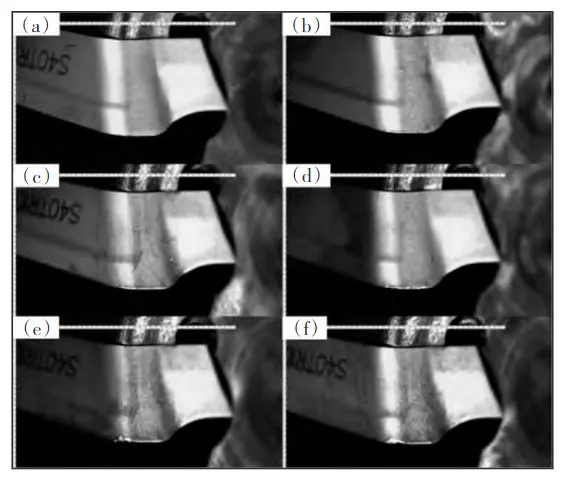

(3) Using the STFT transform, the time-frequency domain spectrum of the signal is made, and the window size is adjusted to a suitable and uniform resolution in the time domain and frequency domain, and the results, as shown in Figure 3.

(4) Take the intrinsic frequency of the toolbar as the base frequency, search for the maximum value of the frequency in the neighborhood of the frequency at each moment of the machining period, and then take the average value of the frequency in the machining period.

(5) The same as (4), take the base frequency of 2 times, 3 times, 4 times, 5 times the frequency frequency calculation of the average maximum value of the high-frequency region signal in the base frequency of the multiple times the frequency of the existence of the great value.

(6) Generate the feature vector representing this processing.

The feature vectors obtained from (4) and (5) are normalized and the time series of the feature vectors are generated according to the processing order, which is used as the input for training/testing of the RNN.

-

Modeling based on recurrent neural network

In the actual machining process, the milling cutter will be used continuously, and the wear of the cutter will rise continuously.

Therefore, the collected signals not only depend on the parameters of the current round of machining experiments, but also have a close relationship with the state of the tool’s last machining in the round of experiments, while the state of the last machining can be obtained from the signals collected from the last machining. Therefore, considering from the point of view of the tool’s full life cycle, the torque signals collected from this tool in the whole round of experiments should be an inextricably linked whole and the sequential order of its inputs cannot be switched;

The Recurrent Neural Network (RNN), on the other hand, is a kind of deep neural network used to process sequential data and predict trends, which possesses the ability to correlate historical input data in line with the milling cutter’s machining process.

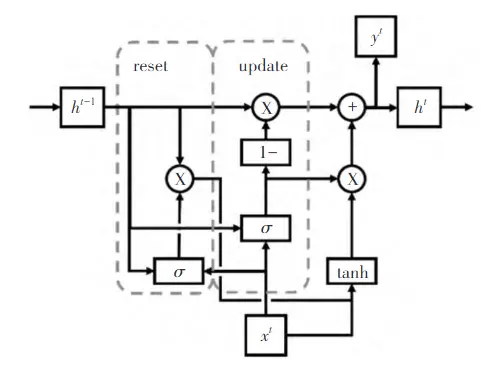

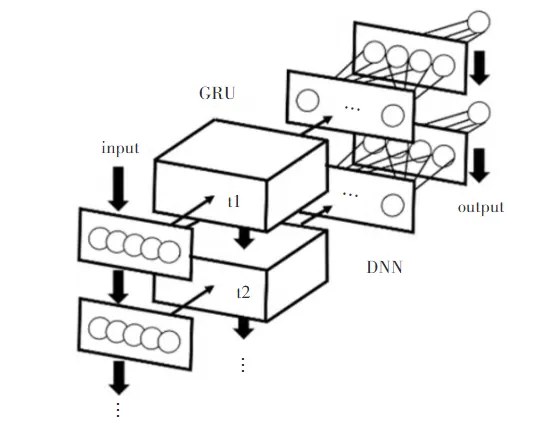

Gate Recurrent Unit (GRU) is a type of recurrent neural network, which adds update gate and reset gate to the simple RNN, as shown in Fig. 4.

The update gate is used to control how much state information from the previous moment is brought into the current state, the larger the value of the update gate is, the more state information from the previous moment is brought into the current state.

The reset gate controls how much information from the previous state is written to the current candidate set, the smaller the reset gate, the less information from the previous state is written.

Compared to simple RNNs, it is able to solve the problems of long term memory and backpropagation where the gradient vanishes or explodes very well.

Compared with LSTM (Long-Short Term Memory), which can also solve the gradient problem, GRU achieves similar results, while the training efficiency is higher, and the user can iteratively select hyperparameters faster, reducing the cost of debugging time [7].

The final constructed recurrent neural network consists of a two-layer GRU network and two fully connected layers;

After supervised training, the network is able to map the online signal characteristics of the tool to the percentage of remaining life, as shown in Fig. 5.

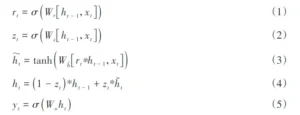

The GRU module in this network consists of two layers of standard GRUs connected in series, and the forward transfer equation of this part can be expressed by the following formula.

In Eq:

𝑥𝑡– the input vector of the layer at time 𝑡;

𝑦𝑡– the output vector of the layer at time t and is used as the input vector xt of the next layer;

σ – sigmoid activation function;

𝑟𝑡, 𝑧𝑡– the values of reset gate and update gate of the layer at time 𝑡;

ℎ𝑡 – the information that is continuously passed in the time series;

𝑤𝑟, 𝑤𝑧, 𝑤ℎ , 𝑤𝑜– weights that need to be obtained after training.

Titanium alloy milling experiment

Experiments using the blank material for Ti6Al4V, size (200 × 150 × 40) mm, milling machine tool for the Swiss production Starrag LX051 machine.

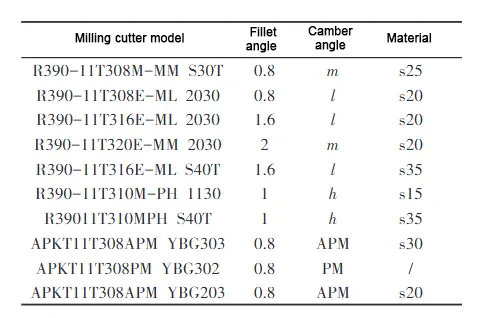

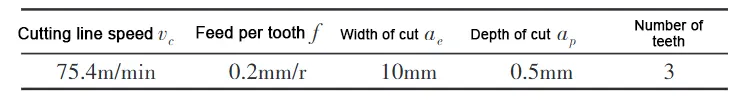

The features processed in the milling experiment are flat surfaces, and the tool is an indexable vertical milling cutter, which is processed in the way of smooth milling, and the selection of the tool and the parameters of processing are shown in Table 1 and Table 2.

Experiments through the spike shank to collect cutting torque signals, sampling frequency of 2500Hz, experiments in the tool to go through 150mm (blank width) for a machining, measuring and recording a surface roughness Ra, every 15 times processing records a tool after the face wear Vb.

Tool to machining after the face wear to reach half the depth of cut for the life of the experiment in order to obtain the rapid wear of part of the data, to reach the life of the tool to continue processing to wear up to 0.3mm.

The clamping for the experiment is shown in Fig. 6. The wear of the back face taken under a microscope is shown in Fig. 7.

Application of Predictive Modeling to Experiments

-

Experimental data processing

Packet loss often occurs when the sensor collects signals, and there are a series of null values and outliers in the collected data, so the features calculated by directly using the collected signals may be inaccurate.

The null values in data processing are interpolated using the cubic spline method, and the elements that deviate from the mean value by more than three times the standard deviation are identified as outliers, and the difference is carried out using the cubic spline; the realization steps are as follows:

(1) Calculate the duty cycle of the processing signal during continuous processing, and segment the data according to the maximum common factor of the processing time and the unprocessed time.

(2) Label the signal segments, with the left-low-right-high data segment marked as the rising edge, the left-high-right-low data segment marked as the falling edge, and the data between the rising edge and the falling edge after the rising edge is labeled as the processing signal.

(3) Take the set of processed signals and calculate the mean value xˉ and standard deviation σ.

(4) Replace the data with deviation greater than 3σ with null value.

(5) Three times spline interpolation is performed on the null value, and three sample points 𝑡0, 𝑡1, 𝑡2, tempty, 𝑡3, 𝑡4, and 𝑡5 before and after the null value are taken as the reference for interpolation.

(6) After the data are removed from outliers and nulls, the inputs for the training and test sets are constructed using the method of extracting torque signal features in Section II.

-

Neural Network Training

In order to obtain the remaining life labels for the training set, it is necessary to convert the available wear data into a percentage of the tool’s already useful life.

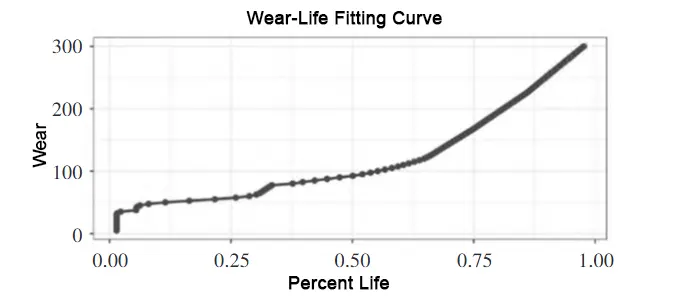

The wear-life mapping relationship is constructed using the DNN model and the tool wear data measured in the experiment and its corresponding life percentage data;

The wear sequences in the training set of tools are passed through the model to obtain the lifetime sequences as labels (outputs) for the recurrent neural network training set.

The final fitting result of the DNN is shown in Fig. 8.

There is a period of rapidly increasing wear when the tool is first machined, which is called initial wear;

After that, there is a slow increase in wear from 7% to 60% of the life, which is the normal wear phase;

In the final stage, the slope of the tool wear increases significantly, the wear accelerates, and the tool is at the end of the normal wear stage and changes to the severe wear stage.

Since the life of each tool is not uniform and the input length is not certain, the input is processed by unifying the length and embedding the 0 vector;

A Mas-king layer is added before the input GRU to filter invalid time steps;

After two layers of GRUs, the original feature dimensions are increased and then compressed using a fully connected layer;

The fully-connected network uses a dropout method with a 30% chance of random failure to ensure that the features are mainly recognized in the GRU part and to prevent the fully-connected layer from overfitting;

The input is a sequence of tool torque signal feature vectors, the output value is a continuous value rather than the classification label of SoftMax output, the output of the training set can not be normalized, so in the DNN part of the network must be used as an activation function of Relu (Rectified linearunits) to ensure that outputs greater than 1 can be effectively fitted, and at the same time to reduce the probability of overfitting [8];

The network uses Adam to optimize the gradient descent, using L2-loss as the loss function, as shown in equation (6).

Where: 𝑖 – a certain dimension of the output vector; N – the size of each batch in the training set.

The batch is taken as the whole training set and the epoch is taken as 800, it can be observed that after 800 times of gradient descent, the loss is 0.004, and it is difficult to make the loss function smaller.

-

Test set validation

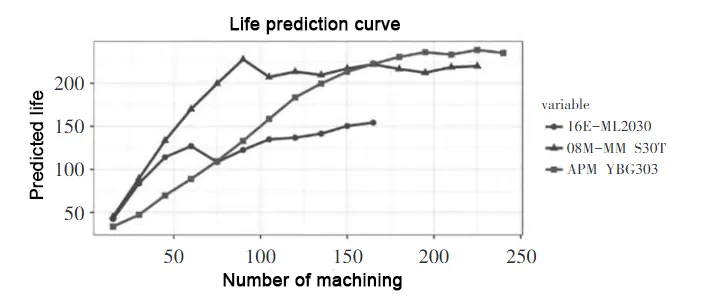

After the training was completed, the three tools of the test set:

R390-11T316E-ML 2030, R390-11T308M-MM S30T, and APKT11T308APM YBG303 were inputted with the signal feature timing sequences, and the curves of the predicted values of the life with the number of experiments were obtained, as shown in Figure 8.

As the machining of the test set of tools advances, the sequence of inputs to the model will continue to get longer.

The predictions for the three tools were obtained at 30% of the life of the test cuts, with actual lives of 83, 89 and 50% as predictions, and they all converged to the actual life, as shown in Figure 9.

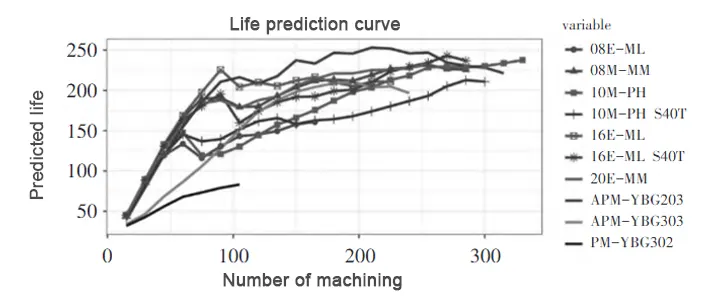

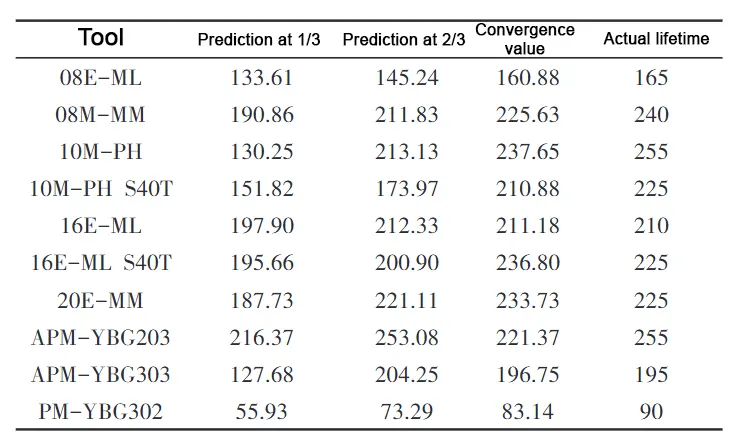

In order to confirm the ability of the model to reduce the number of test cuts, the torque signals of 10 tools with unmeasured wear, machined continuously until the tool was damaged, and whose actual life was obtained, were collected, and the characteristic sequence of the torque signals over their entire life cycle was input to obtain the curve of the predicted life with the number of experiments, as shown in Fig. 10.

The horizontal coordinate in the graph is the number of groups machined, and each group represents 15 tools.

The predicted model convergence values of 83, 84, 54, 72, 94, 82, 80, 98, 65, 67% are obtained for these 10 tools at 1/3 of the life of the test cuts, and 90, 94, 90, 82, 101, 85, 95, 114, 104, 88% are obtained at 2/3 of the life of the test cuts, and the predicted values of this model can increase rapidly to close to the convergence value in the early stage of the test cut experiment. The model was able to rapidly increase the predicted values in the early stage of the test cutting experiment to near converged values.

The final convergence of the prediction model for the 10 tools is 14.56 times, which is within the standard error of the measured set of machining (15 cuts), and the prediction results are in high agreement with the actual life.

It can be obtained that the more adapted the tool to the machining, the later the slope turning point in the life prediction curve, and the higher the peak value at the turning point; for the same number of test cuts, the more adapted the tool to the machining, the higher the predicted life;

Therefore, in the practical application of the model, the predicted value after the turning point of the life curve should be taken as the effective predicted value. For the 10 tools in the experiment, this turning point usually occurs at 1/3 of the converged life.

Taking the model output 1/3 of the convergence value of life as a judgment value of tool machining adaptability, it can be machined on a group of tools, eliminating the lowest predicted value of a few tools, and selecting the longest predicted life of a few tools as the optimal option for the group, which reduces the time consumed in the selection of the tool test cutting (2/3 of the original test-cutting time in the current experiment).

Conclusion

A tool life prediction model based on the feature extraction of high-frequency signal components of torque is proposed, which takes the experimental data of titanium alloy milling of different tools under specific cutting parameters as the training set;

After the training is completed it is able to use the feature sequence of the tool in continuous machining to reach the damage process as the input of the model, and the wear of the tool in the whole life cycle through the wear life curve to get the life index as the model output.

The test data obtained from experiments with different tools were tested to verify the tool applicability of the model;

The model can appear the inflection point of the life prediction curve when the tool is machined to the vicinity of 1/3 of the life, and the prediction value of this inflection point can be very close to the actual life of the tool;

The model can speed up the selection of titanium alloy milling tools, reducing the time consumed and machining costs.