Custom Online Brass CNC machining services for you

Brass CNC machining services

- 24/7 operations in our machine shop guarantee fast lead times

- Tolerances up to ±0.0004″ (0.01mm)

- Lead times as short as 1 day.

Overview of Brass in manufacturing

Tonza’s Bespoke Online Brass CNC Machining Service offers high-precision machining for Brass parts, ensuring exceptional precision and quality. Using state-of-the-art CNC equipment, we expertly manage challenging structures while offering fast turnaround times and personalized services tailored to fulfill your precise job criteria.

Properties

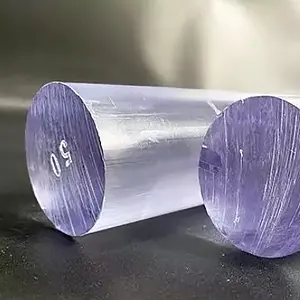

Brass is a metal alloy primarily composed of copper and zinc, known for its excellent malleability, corrosion resistance, and attractive gold-like appearance. It is commonly used in musical instruments, decorative objects, and plumbing fixtures due to its acoustic properties and aesthetic appeal. Brass has a relatively low melting point, making it easy to shape and mold. It is also highly conductive of heat and electricity, making it a popular choice for electrical connectors and heat exchangers.

Parameters

Brass instruments are characterized by their bright, metallic sound. The main parameters of brass include material composition (usually a combination of copper and zinc), bell size, valve mechanism, and bore size. These factors determine the instrument's tone quality, projection, and overall playability. Additionally, the weight and shape of the instrument can impact a player's comfort and endurance during performance. Understanding these parameters is crucial for selecting the right brass instrument to suit a player's musical style and preferences.

Precautions

When machining Brass, ensure proper ventilation to prevent inhalation of fumes. Use coolant to avoid overheating and wear protective gear such as gloves and eye protection. Secure workpieces tightly to prevent shifting. Check for any defects or impurities in the material before starting. Follow proper machining procedures to avoid accidents and ensure quality results. Regularly maintain and clean machinery to prolong its lifespan. Always follow safety guidelines provided by the manufacturer.

Why Cooper is ideal for CNC machining?

Brass is considered ideal for CNC machining due to its excellent machinability and versatility. It is a soft metal, which makes it easy to shape and cut using CNC machines, resulting in precise and high-quality parts. Brass also offers good corrosion resistance, making it suitable for a wide range of applications in various industries. Additionally, brass has superior thermal conductivity properties, facilitating efficient machining processes and reducing the risk of tool wear. Its aesthetic appeal, availability in different finishes, and cost-effectiveness further contribute to its popularity in CNC machining. Overall, brass proves to be a reliable choice for producing intricate and accurate components with excellent surface finish.

Benefits of working with copper at TONZA

Working with Brass at TONZA offers numerous benefits for individuals looking to elevate their craftsmanship. Brass is a versatile material that is both durable and aesthetically pleasing, making it an ideal choice for a wide range of projects. At TONZA, we provide high-quality Brass materials that are easy to work with and offer a polished finish. Additionally, Brass is known for its corrosion-resistant properties, ensuring that your work will stand the test of time. Whether you are a seasoned professional or just starting out, working with Brass at TONZA can help you create stunning pieces that will impress clients and colleagues alike.

Why Choose ours Brass CNC machining services?

Each component is produced to tight tolerances of ±0.01 mm, delivering a accurate match to specification.

We collaborate with reliable material providers to provide high-quality standard materials for your items.

Obtain quick and accurate DFM assessments to optimize your blueprint for fabrication and expedite manufacturing.

With extensive market knowledge, we offer dependable the material CNC machining options.

Capabilities of Brass CNC machining services

Our CNC machines deliver precision tolerances that meet industry standards, ensuring consistent accuracy and seamless component fit.

Tolerances

±0.05mm

Premium-grade tech solutions to provide you with crafted for superior durability.

Max part size

500 mm x 500 mm

Premium-grade tech solutions to provide you with top-tier product performance.

Min part size

5 mm x 5 mm

Extensive hands-on skills, know-how in producing complex parts.

Lead Time

< 10 days

Strong and structured management system, and optimized workflow for speed and quality

Surface Finish

Ra 0.8-1.6 µm

Streamlined workforce management, and enhanced output.

Wall Thickness

0.75 mm

Years of practical expertise, capable of handling complex manufacturing challenges.

Brass Material Properties

Optimize your designs for manufacturability with our expert guidelines and feedback, ensuring the best results in CNC machining.

| Brass Grade | Ultimate Tensile Strength (ksi) | Elongation (%) | Hardness (HRB) | Corrosion Resistance | Machinability | Common Applications |

|---|---|---|---|---|---|---|

| C360 (Free-Cutting Brass) | 58–68 | 25–30 | 78–85 | ⭐⭐⭐ (Moderate) | ⭐⭐⭐⭐⭐ (100%) | Precision CNC parts, valves, gears, fittings, fasteners |

| C260 (Cartridge Brass) | 45–58 | 30–45 | 55–75 | ⭐⭐⭐⭐ (Good) | ⭐⭐ (30%) | Deep-drawn parts, ammunition casings, plumbing hardware, musical instruments |

| C464 (Naval Brass) | 60–70 | 25–35 | 80–90 | ⭐⭐⭐⭐⭐ (Excellent – esp. marine) | ⭐⭐⭐ (35–40%) | Marine hardware, propeller shafts, condenser tubes, ship fittings |

| Leaded Brass Alloys (e.g., C345, C335) | 45–65 | 15–30 | 70–85 | ⭐⭐–⭐⭐⭐ (Fair to Moderate) | ⭐⭐⭐⭐–⭐⭐⭐⭐⭐ (85–90%) | Screws, bushings, watch parts, plumbing fittings, high-volume turned parts |

⭐ Legend

- Tensile Strength: Approximate range depending on temper (annealed, half-hard, etc.)

- Elongation: Indicator of ductility (higher = better formability)

- Hardness: Rockwell B (HRB) scale

- Corrosion Resistance:

⭐ = Low

⭐⭐⭐ = Moderate

⭐⭐⭐⭐ = Good

⭐⭐⭐⭐⭐ = Excellent -

Machinability: Rated relative to C360 (100%)

✅Quick Selection Insights

-

For high-speed machining → Choose C360 or Leaded Brass Alloys

-

For deep drawing/forming → Choose C260

-

For marine/corrosive environments → Choose C464 (Naval Brass)

-

For general-purpose turned parts → Choose Leaded Brass (C345, C335)

Commonly Used Brass Types

Our CNC equipment deliver tight tolerances that meet industry standards, securing consistent accuracy and perfect part fit.

| Property | C360 |

|---|---|

| Machinability | ⭐⭐⭐⭐⭐ (100% baseline – excellent) |

| Corrosion Resistance | ⭐⭐⭐ (Moderate – good in dry environments, not ideal for marine exposure) |

| Ductility | ⭐⭐ (Moderate – less ductile due to lead content) |

| Cost Efficiency | ⭐⭐⭐⭐ (High – economical for high-volume machining) |

| Strength | ⭐⭐⭐ (Moderate – suitable for structural and mechanical components) |

| Surface Finish | ⭐⭐⭐⭐ (Excellent – smooth finish due to fine chip formation during machining) |

| Best Use Case | High-speed CNC machining of intricate, tight-tolerance components requiring fine finish |

Why Choose Brass C360?

Choose Brass C360 when you need a material that can withstand high-speed machining without sacrificing quality or efficiency. It’s especially valuable in automated screw machines, CNC lathes, and multi-axis milling setups where accuracy, speed, and surface quality are critical. Its balance of strength, machinability, and cost-efficiency makes it a preferred material across multiple industries—from electronics and plumbing to aerospace and automotive.

C360 Brass is the go-to material when maximum machinability, clean surface finishes, and cost-effective production are priorities—particularly in automated machining environments. Leaded brass alloys are copper-zinc alloys with small additions of lead (typically 1–3%). The lead enhances machinability by acting as a chip breaker and lubricant, making these alloys ideal for high-speed, high-precision machining processes like CNC turning and screw machining.

| Property | C260 |

|---|---|

| Machinability | ⭐⭐ (30% – Fair) |

| Corrosion Resistance | ⭐⭐⭐⭐ (Good – resists atmospheric and mild chemical corrosion) |

| Ductility | ⭐⭐⭐⭐⭐ (Excellent – one of the most ductile brass alloys) |

| Cost Efficiency | ⭐⭐⭐ (Moderate – higher copper content increases cost slightly) |

| Strength | ⭐⭐⭐ (Moderate – good for forming applications) |

| Surface Finish | ⭐⭐⭐⭐ (Very Good – takes polish and plating well) |

| Best Use Case | Deep drawing and forming requiring high ductility, good corrosion resistance |

Why Choose Brass C260?

Choose Brass C260 when your application demands exceptional formability, aesthetic appeal, and reliable corrosion resistance. It’s especially effective for manufacturing components that undergo deep drawing, stamping, or cold forming. While not the best for high-speed machining, it excels where shaping, performance, and finish are priorities.

Brass C260, commonly known as Cartridge Brass, is a high-copper alloy composed of approximately 70% copper and 30% zinc. It is renowned for its exceptional ductility, excellent corrosion resistance, and good cold workability, making it the preferred material for deep drawing and forming operations.

| Property | C280 |

|---|---|

| Machinability | ⭐⭐ (40% – Fair) |

| Corrosion Resistance | ⭐⭐⭐⭐ (Good – especially resistant to seawater corrosion) |

| Ductility | ⭐⭐⭐ (Moderate – less ductile than C260 but workable when hot) |

| Cost Efficiency | ⭐⭐⭐⭐ (Good – relatively low-cost with high performance in structural applications) |

| Strength | ⭐⭐⭐⭐ (High – stronger than typical yellow brasses) |

| Surface Finish | ⭐⭐⭐ (Moderate – takes polish but not as well as higher copper brasses) |

| Best Use Case | Hot-rolled or hot-forged components requiring strength, durability, and seawater resistance |

Why Choose Brass C280?

Choose Brass C280 when your application demands a combination of strength, corrosion resistance, and economic value, especially in marine, architectural, or industrial settings. Its durability in harsh environments and ease of hot forming make it ideal for fabrications where other brasses might lack strength or longevity.

Benefits

- Reliable performance in marine and industrial environments

- Cost-effective alternative to pure copper or naval brass in structural applications

- Excellent for hot-rolled, extruded, or forged products

- Good choice for load-bearing components that need corrosion resistance

- Available in a wide range of forms: sheets, plates, bars, and tubes

| Key Factor | Consideration | Best Choice |

|---|---|---|

| Load/Strength Requirements | Light to moderate loads, low wear | CU1 |

| Moderate loads, occasional shock loading | CU2 | |

| High static or dynamic loads, continuous operation | CU3 / CU4 | |

| Corrosion Environment | Mild atmosphere, dry indoor use | CU1 / CU2 |

| Humid, slightly corrosive or industrial environments | CU2 / CU3 | |

| Saltwater, marine, or chemical exposure | CU3 / CU4 (Excellent resistance) | |

| Wear Resistance | Low wear (non-critical bushings, spacers) | CU1 / CU2 |

| High wear (bearings, thrust washers, moving parts) | CU3 / CU4 | |

| Machinability Priority | Simple machining, lower production speed | CU1 / CU2 |

| Moderate to high-speed machining needed | CU4 | |

| Cost Sensitivity | Budget-focused applications | CU1 |

| Performance-critical and long-life components | CU3 / CU4 |

Surface Treatment of Brass

We yield a full range of CNC materials for custom-machined components, including aluminum, steel, brass, plastics, and over 100 other materials.

Brushing

Polishing

Tumbling

Anodizing

Black Oxide

Electroplating

Powder Coating

Alodine

Passivation

Electroless Plating

Application Industries of Brass

From vehicle to aviation, Tonza’s CNC machining meets the exact needs of multiple industries. We partner with independent innovators, developers, and major companies, serving over 1,000 clients worldwide.

Choice Other Metal Materials Machining

Our CNC machines provide tolerances for reliable accuracy and perfact part integration.

Brass CNC machining services

Cooper CNC Machining Service

Aluminum CNC Machining Service

Stainless Steel CNC Machining Services

Mild Steel CNC Machining Services

Magnesium CNC Machining Services

Titanium CNC Machining Services

Choice Other Plastics Materials Machining

Our CNC machines deliver precision tolerances that meet industry standards, ensuring consistent accuracy and seamless component fit.

ABS CNC machining services

PMMA CNC Machining Service

Nylon CNC Machining Service

PC CNC Machining Service

PP CNC Machining Services

PET CNC Machining Services

PEI CNC Machining Services

POM CNC Machining Services

PTFE CNC Machining Services

PEEK CNC Machining Services

HDPE CNC Machining Services

UHMW CNC Machining Services

FAQ about Brass machining

Curious about our Brass machining? Here are the FAQs with everything you need to know.

TONZA machines a variety of aluminum alloys including 6061, 7075, 2024, and 5052, ensuring your parts meet both structural and performance requirements.

TONZA provides milling, turning, drilling, and tapping for aluminum using advanced CNC equipment capable of producing complex geometries with tight tolerances.

TONZA routinely achieves tolerances of ±0.05 mm, with tighter tolerances down to ±0.01 mm available upon request for precision-critical components.

Yes, TONZA offers Type II and Type III anodizing to enhance corrosion resistance, wear protection, and aesthetic appearance of your aluminum parts.

TONZA specializes in both prototyping and small to medium-volume production, giving you flexibility to scale as your project evolves.

TONZA offers lead times as short as 3 days, depending on complexity and volume, with expedited services available for urgent projects.

Yes, TONZA uses high-precision CNC machines and optimized toolpaths to handle complex features, thin walls, and intricate aluminum designs.

TONZA provides a wide range of finishes, including anodizing, bead blasting, polishing, powder coating, and chromate conversion, tailored to your application.

TONZA delivers aluminum CNC parts to industries such as aerospace, automotive, medical, robotics, and consumer electronics.

TONZA can precisely tap threads or install helicoils and inserts into your aluminum parts, ready for assembly right out of the box.

TONZA uses optimized fixturing, precision toolpaths, and controlled machining parameters to minimize stress and avoid part deformation.

Yes, TONZA provides Design for Manufacturing (DFM) support to ensure your aluminum part is optimized for both performance and cost efficiency.

TONZA accepts STEP, IGES, STL, and other standard CAD formats. Simply upload your file for a fast and accurate quote.

TONZA’s machining centers can handle aluminum components up to 1 meter long, ideal for structural or enclosure parts.

Visit the TONZA website, upload your CAD file, select your aluminum alloy and quantity, and receive a detailed quote within 24 hours.