Custom Laser Cutting Services — Fast, Accurate, Online

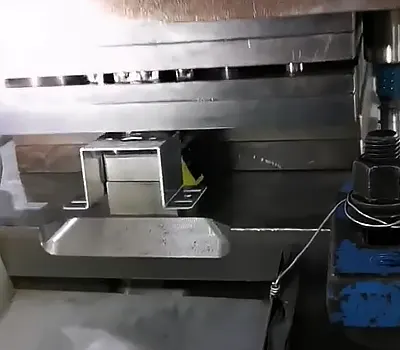

Online Metal Stamping Service

Request a free sheet metal bending quote and receive expert design-for-manufacturability (DFM) feedback within 24 hours. Enjoy rapid turnaround with lead times as fast as 3–5 days.

- Bending Thickness Up to 60 mm

- Maximum Part Size 1.5 m x 1.5m

- Bend Angle +/- 1°

What is Metal Stamping?

Metal stamping is a manufacturing process that uses dies and high-pressure presses to shape flat metal sheets into specific forms. It involves operations such as punching, blanking, bending, embossing, flanging, and coining to produce parts with precise dimensions and complex geometries. Metal stamping is widely used in industries like automotive, aerospace, electronics, and appliances due to its efficiency, consistency, and ability to produce high volumes of components with tight tolerances.

Type of Metal Stamping

Sheet metal bending is extensively utilized in numerous industries for its high precision, rapid processing, and efficient material usage, allowing for the creation of complex shapes with minimal waste.

Blanking

Forming

Deep drawing

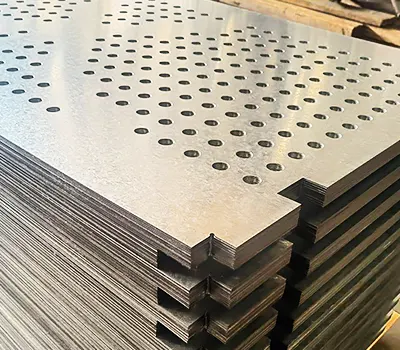

Piercing

Bending

Coining

Curling

Embossing

Surface treatment solution

We provide high-quality metal stamping services, delivering precision-engineered, expertly finished components at highly competitive prices.

Brushing

Sand Blast

Polishing

Tumbling

Anodizing

Painting

Black Oxide

Electroplating

Powder Coating

Alodine

Passivation

Electroless Plating

Why Choose Ours Metal Stamping Service?

Our experienced engineering team utilizes advanced metal stamping technology and rigorous quality control procedures.

Using advanced stamping machines and high-precision molds, we produce custom metal parts with outstanding speed and efficiency.

Our experts support you at every stage—from material selection to stamping production—ensuring you consistently achieve the best results for your project.

Capabilities of Metal Stamping Services

We provide high-quality metal stamping services, delivering precision-engineered, expertly finished components at highly competitive prices.

control up to ±0.01 mm

In-house custom mold design and fabrication

Range from 0.2 mm to 6 mm

Up to 250 tons

Prototypes to mass production

Stainless steel, Carbon steel, and etc.l

Design Guidelines

Optimize your designs for manufacturability with our expert guidelines and feedback, ensuring the best results in injection molding service

Material Selection

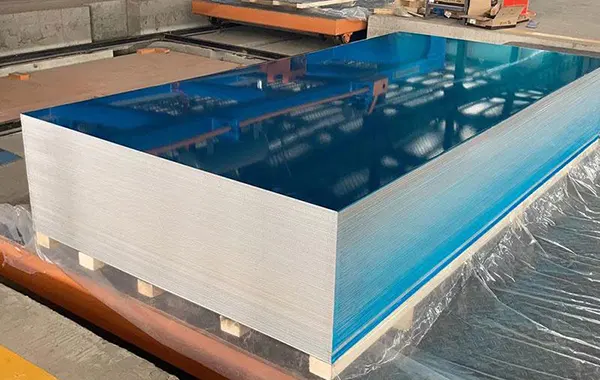

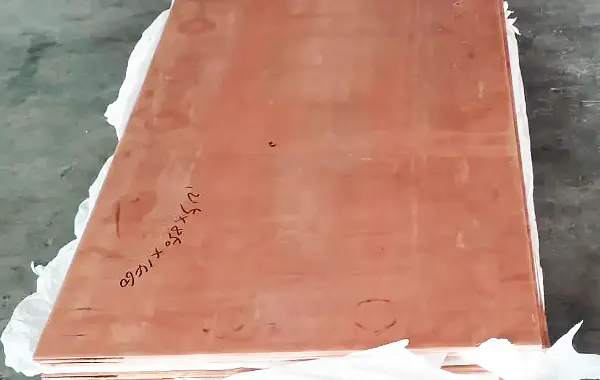

Carbon steel, stainless steel, aluminum, copper, brass Consider formability, strength, and corrosion resistance for your application

2. Recommended thickness: 0.2 mm – 6.0 mm

Part Geometry

2. Avoid unnecessary bends or deep draws unless required

3. For deep-drawn parts, maintain a smooth wall-to-base transition (use radius)

Bending Guidelines

2. Bend radius: ≥ 1× material thickness to avoid cracking

3. Avoid placing holes too close to bends (distance ≥ 2× thickness + bend radius)

Hole and Slot Design

2. Minimum distance between holes: 2× thickness

3. Avoid placing holes or slots too close to edges

Deep Drawing Tips

2. Use generous radii at corners and transitions

3. Uniform wall thickness preferred

Draft Angles

2. Especially important for deep drawn or formed shapes

Avoid Sharp Corners

Marking & Identification

2. Ensure text height ≥ 1 mm and depth ≤ 0.2 mm

Materials for Metal Stamping

Overmolding technology represents a breakthrough in multi-material integrated manufacturing, offering a wide range of material pairing possibilities to meet diverse industrial needs.

Aluminum

Stainless Steel

Copper

Cold Rolled Steel

Hot Rolled Steel

Hot-dip galvanization

Applications of Metal Stamping

Sheet metal bending is extensively utilized in numerous industries for its high precision, rapid processing, and efficient material usage, allowing for the creation of complex shapes with minimal waste.

FAQ

We provide high-precision metal stamping services that ensure seamless bonding, enhanced durability, and a perfect fit for complex multi-material parts.

Common materials include carbon steel, stainless steel, aluminum, brass, copper, and other sheet metals depending on the application and required strength.

Stamping is widely used in the automotive, aerospace, electronics, appliance, and medical industries for producing high-volume, precision metal parts.

Stamping includes blanking, bending, coining, drawing, embossing, flanging, and piercing. These processes can be done individually or in a combined die set.

Progressive die stamping performs multiple operations in one press stroke across multiple stations, ideal for high volumes. Single-stage (or single-hit) stamping does one operation per stroke, suited for small production runs.

Tolerances depend on material, tooling, and design, but precision stamping can achieve tolerances as tight as ±0.01 mm with proper control.

Costs can be reduced by optimizing part design for manufacturability, using standard materials, minimizing tight tolerances, and ordering higher volumes.

Lead time depends on complexity, volume, and tooling. Prototype runs may take 1–2 weeks, while production tooling and delivery can take 4–6 weeks.

Yes, we provide DFM (Design for Manufacturability) assistance to help optimize your design for efficient, cost-effective stamping.

Absolutely. Our stamping facilities are equipped for both low and high-volume production, ensuring consistency, speed, and quality.