CNC Machining Services forPiedmont, Italy

Your CNC Solution, Delivered Fast.

TonzaMakings is a leading provider of CNC machining services for Piedmont, offering high-quality precision machining solutions to meet the needs of various industries. With a team of experienced professionals and state-of-the-art equipment, we are dedicated to delivering top-notch machining services to our clients in Piedmont. Our commitment to quality, reliability, and customer satisfaction sets us apart from the competition in the region.

At TonzaMakings, we understand the importance of precision and efficiency in CNC machining. Our team is equipped with the latest technology and expertise to handle projects of all sizes and complexities. Whether you need prototype development, toolmaking, or production runs, we can customize our services to meet your specific requirements.

We take pride in delivering exceptional results that exceed our clients’ expectations and contribute to their success in the market.

Most important Joining

"We are a professional machining service provider based in China, seeking participants to establish a global network based on win-win. If you are involved in the manufacturing industry—whether you operate your workshop or have engineering expertise—we welcome the opportunity to collaborate. Please get in touch with us to explore potential cooperation."

TonZamaking

Type of CNC Machining Services for Piedmont

Our proficiency in

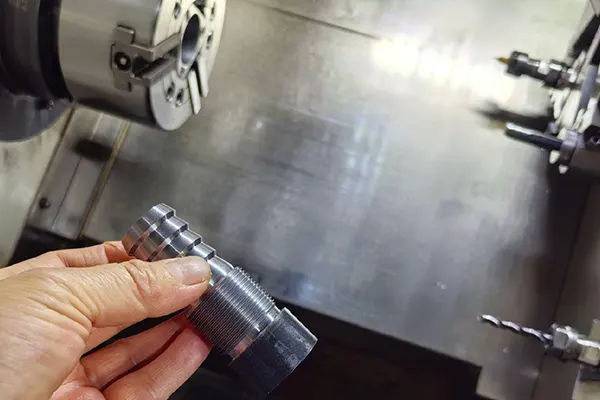

CNC milling, turning, and 5-axis machining, we deliver consistent, exceptional accuracy parts with rapid and reliability across a wide range of industries.

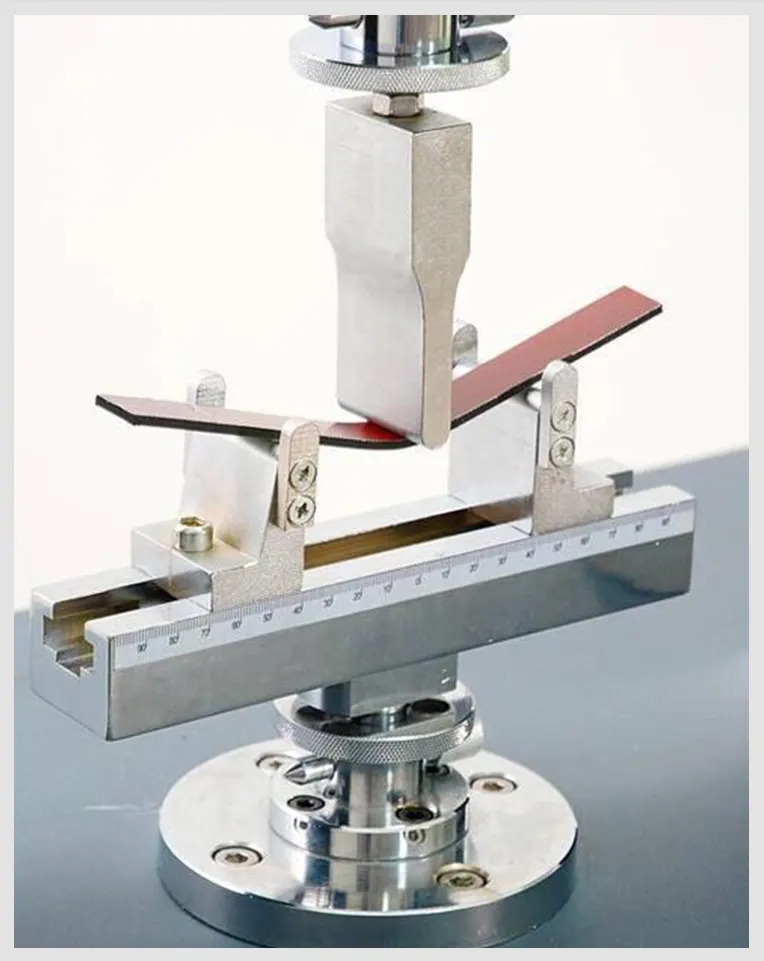

CNC Milling services

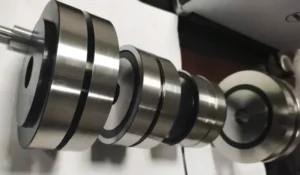

CNC Turnning services

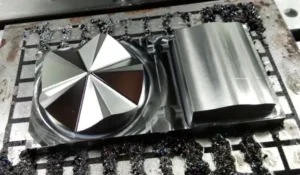

5-Axis CNC Machining

Precision Machining Services

Capabilities of CNC Machining Services for Piedmont

Our CNC machines consistently uphold strict measurement standards that are engineered to meet demanding industry requirements, optimizing tolerance for perfect fit and function.

Tolerances

±0.05mm

Sleek and innovative design to deliver outstanding construction and finish.

Max part size

200 x 80 x 100 cm

Enhanced with cutting-edge fabrication equipment, aimed at precise customer fulfillment.

Wall Thickness

0.75 mm

Equipped with highly accurate machining systems, geared toward meeting unique client specifications.

Lead Time

< 10 days

Effective management systems, and quick and consistent output.

Why Choose Ours CNC Machining Services?

Providing remarkable results driven by experience, focus, and strategic insight.

Consulting closely with clients to align with their particular needs and goals.

Harnessing the power of the latest technology and advanced machinery to deliver precision and efficiency.

Providing outstanding value while maintaining the highest standards of quality and precision.

CNC Machining Solutions for Piedmont, Italy

With extensive industry knowledge, we excel in CNC milling, turning, and 5-axis machining, providing high-quality parts with fast and stability across diverse industries.

Rapid prototyping | Bridge Production | Massive Production |

|---|---|---|

Smaller Tool Stock, More Axis | Big Tool Stock, More Axis | Bigger Tool Stock, Less Axis |

Predominantly standard fixtures. | A few custom-made fixtures. | Custom Made Fixture |

Highly precise with significant variance. | Highly precise with significant variance. | Accurate with slight variance. |

Very expensive per Unit | expensive per Unit | Low per unit |

LT: 1-4 business days | LT: 5-12 business days | Lead Time: 2-4 weeks |

Capability: 1-50 pcs | Capability: 51-10,000 pcs | Capability: Above 10,001 pcs |

Surface Finishes for Italy Customer

We supply a comprehensive range of surface finishes options to meet your functional and visual needs.

Brushing

Sand Blast

Polishing

Tumbling

Anodizing

Painting

Black Oxide

Powder Coating

Electroplating

Alodine

Passivation

Electroless Plating

Certifications & Quality Standards

Tonza produce CNC components with uniform accuracy, meeting precision tolerances and enabling precise integration of parts.

Tolerances are maintained in accordance with ISO 2768 standards.

TonZa boasts an ISO9001 certified quality management system and is dedicated to strictly following quality control procedures in its production process.

By upholding these stringent standards, TonZa ensures the delivery of high-quality products to Piedmont’s discerning customers.

Maintaining a commitment to quality control is essential for TonZa in order to meet the expectations of their clients and uphold their reputation as a trustworthy and reliable manufacturer.

With an emphasis on quality assurance, TonZa aims to consistently produce goods that surpass industry standards and meet the needs of their customers.

Through rigorous quality control measures, TonZa strives to exceed customer expectations and build lasting relationships with Piedmont and its client base.

Other Machining Capabilities

In Piedmont, Italy, we deliver CNC machining, sheet metal fabrication, die casting, and additional manufacturing capabilities.

Injection Molding

Sheet Metal Fabrication

High Pressure Die Casting

Vaccum Casting

3D Printing

CNC Machining Services Locations Near Piedmont, Italy

{Tonza’s long-standing expertise in CNC milling, 5-axis machining, and turning allows us to delivering precision, precise, and resilient precision components.}

TonZa is proud to offer top-notch CNC Machining Services for customers in Piedmont. Our team of highly skilled professionals specializes in providing precise and efficient machining solutions for a wide range of industries. With state-of-the-art equipment and a commitment to excellence, we strive to meet and exceed our customers’ expectations.

From rapid prototyping to high-volume production runs, TonZa has the capability to handle any CNC machining project with precision and accuracy. Our dedication to quality and customer satisfaction sets us apart as a trusted provider of CNC machining services in Piedmont and beyond.

Whether you require intricate components or complex parts, TonZa has the expertise to deliver exceptional results every time.

FAQ

Here, we’ve listed some of the most common questions about CNC machining services for Piedmont, Italy. “If you can’t find a satisfactory answer, feel free to contact us.“

FAQs about CNC Machining Services in Piedmont

1. What is CNC machining and how is it used in Piedmont?

CNC (Computer Numerical Control) machining is a subtractive manufacturing process that uses automated tools to produce high-precision components. In Piedmont, it’s widely used in automotive, aerospace, industrial machinery, and tooling sectors.

2. What CNC machining services are commonly offered in Piedmont?

Typical services include CNC milling, CNC turning, 5-axis machining, wire EDM, drilling, tapping, and surface finishing processes like anodizing or powder coating.

3. Are there specialized CNC machining providers for the automotive sector in Piedmont?

Yes. Piedmont is a major automotive hub (with companies like Fiat in Turin), and many CNC shops are highly experienced in producing car parts, engine components, and transmission systems.

4. What materials can be machined by CNC shops in Piedmont?

Shops handle a wide range of materials including aluminum, stainless steel, titanium, brass, copper, engineering plastics (such as PEEK and Delrin), and special alloys.

5. Can I get custom parts manufactured in low quantities?

Absolutely. Many CNC machining providers in Piedmont specialize in both prototyping and small-batch production for custom parts.

6. Are Piedmont-based CNC machine shops ISO certified?

Many reputable CNC machining companies in the region hold ISO 9001 and/or ISO/TS 16949 certifications, ensuring compliance with international quality and automotive standards.

7. Do CNC machining companies in Piedmont provide design support?

Yes. Several companies offer design-for-manufacturing (DFM) consultation and assistance with CAD/CAM files to ensure optimal results.

8. How long does it take to complete a CNC machining project in Piedmont?

Lead times vary based on complexity and volume, but rapid prototyping can be completed in a few days, with production runs typically ranging from 1–3 weeks.

9. Is international shipping available from Piedmont CNC machining companies?

Yes. Many companies ship globally and offer logistics support for clients across Europe and beyond.

10. What industries rely on CNC machining in Piedmont?

Industries include automotive, aerospace, agriculture, food processing equipment, industrial automation, and medical technology.