Brushing services for you

With a focus on quality, our As Machined services provide parts that achieve Ra 3.2μm and Ra 1.6μm surface roughness directly, without extra finishing steps.

What is Brushing in Surface Treatment?

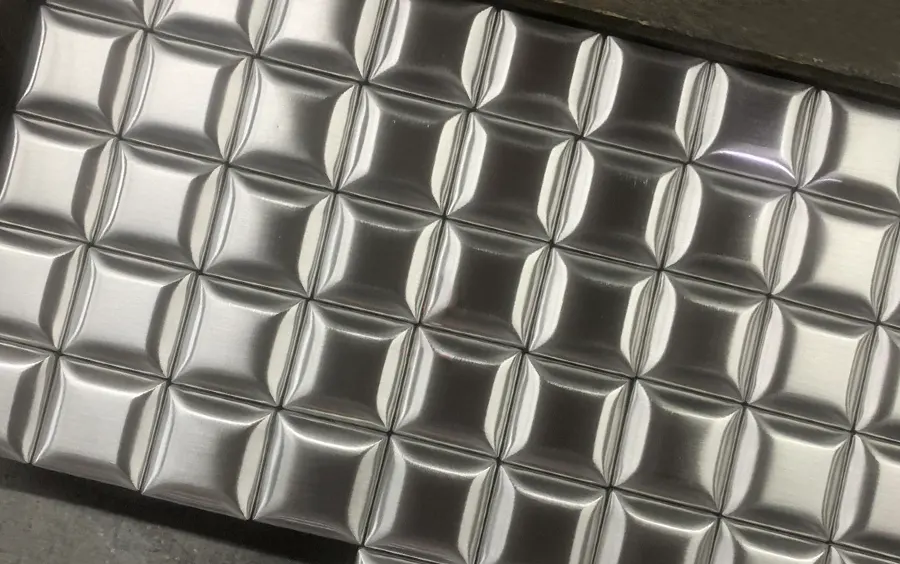

Brushing in surface treatment is a finishing process that uses abrasive brushes (usually made of wire, nylon, or other abrasive filaments) to modify or improve the surface of a material. It’s often applied to metal parts, plastics, and composites for both functional and decorative purposes.

Where It’s Used

- Machined or cast parts → deburring edges.

- Stainless steel panels → decorative hairline finish.

- Before anodizing or plating → prepares a smooth, clean surface.

- After welding → removes discoloration and oxides.

Characteristics

- Non-aggressive compared to grinding/polishing.

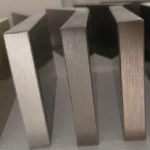

- Leaves a matte or satin-like finish, not glossy.

- Can be automated (robotic brushing) or manual.

Main Feature

Optimize your designs for manufacturability with our expert guidelines and feedback, ensuring the best results in surface treatment

Advantages

- Removes imperfections – effective for deburring, oxide/rust removal.

- Improves adhesion – creates micro-texture for paints, coatings, or adhesives better.

- Decorative effect – produces a uniform satin / hairline finish, widely used.

- Controlled material removal – less aggressive than grinding or sanding.

- Flexibility – works on flat, curved, or complex surfaces.

- Automation-friendly – can be integrated into production lines.

- Cost-effective – relatively simple equipment compared to polishing or blasting.

Disadvantages

- Limited finish quality – cannot achieve mirror-like gloss (that requires polishing).

- Surface directionality – leaves visible grain/lines

- Tool wear – brushes wear down over time, requiring frequent replacement.

- Not deep cleaning – won’t remove heavy scale, thick coatings, or deep scratches.

- Possible contamination – wire brushes can shed particles that may rust or embed in softer materials.

- Limited precision – not suitable when very tight surface roughness or dimensional tolerances are required.

Design Considerations for As Machined Parts

Our CNC systems offer exact specifications that satisfy market norms, ensuring consistent accuracy and flawless piece integration.

Material Selection

Surface Geometry

Surface Roughness & Finish

Functional Requirements

Tolerances & Dimensional Accuracy

Consistency & Process Control

Post-Treatment Considerations

FAQ about Brushing

To help you better understand our surface treatment capabilities, we’ve answered the most frequently asked questions.

Brushing is a mechanical surface finishing process that uses abrasive brushes to clean, deburr, and create a satin or matte texture on metals and other materials. It improves both functional performance and appearance.

Brushing is most commonly applied to stainless steel, aluminum, brass, and other metals. It can also be used on certain plastics and composites, but very soft or brittle materials may not be ideal.

The key advantages include removing burrs and oxides, improving coating adhesion, producing a decorative satin finish, and preparing surfaces for further treatments like anodizing, painting, or plating.

Brushing creates a uniform matte or satin finish with visible grain lines, while polishing produces a glossy, mirror-like surface. Brushing is ideal for functional or aesthetic textures, while polishing is used for high-reflective finishes.

Yes, brushing removes oxides, rust, and impurities that can accelerate corrosion. However, for long-term protection, brushed surfaces are often combined with coatings such as anodizing, passivation, or clear lacquers.

Brushing is widely used in consumer electronics, home appliances, automotive parts, aerospace components, architectural panels, and medical equipment for both decorative and technical purposes.

Brushing removes only a thin surface layer, so dimensional changes are minimal. However, it should not be applied to highly critical tolerance areas unless controlled carefully.

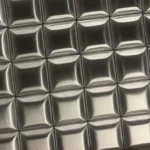

Common finishes include straight-line brushing, circular brushing, and cross-hatch brushing. Each pattern provides a different visual effect and can be specified in the design process.

Brushed stainless steel has a satin appearance with fine grain lines, reducing glare and hiding minor scratches. Polished stainless steel, by contrast, is reflective and smooth but more prone to showing fingerprints and scratches.

Designers should consider material compatibility, grain direction, surface geometry, and protective coatings. Consistency in brushing parameters is critical to achieving uniform and professional finishes.