As Machined Services for you

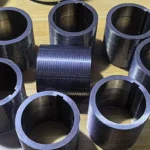

With a focus on quality, our As Machined services provide parts that achieve Ra 3.2μm and Ra 1.6μm surface roughness directly, without extra finishing steps.

What is As Machined in Surface Treatment?

In manufacturing, when you see “As Machined” listed under surface treatment (or surface finish), it means:

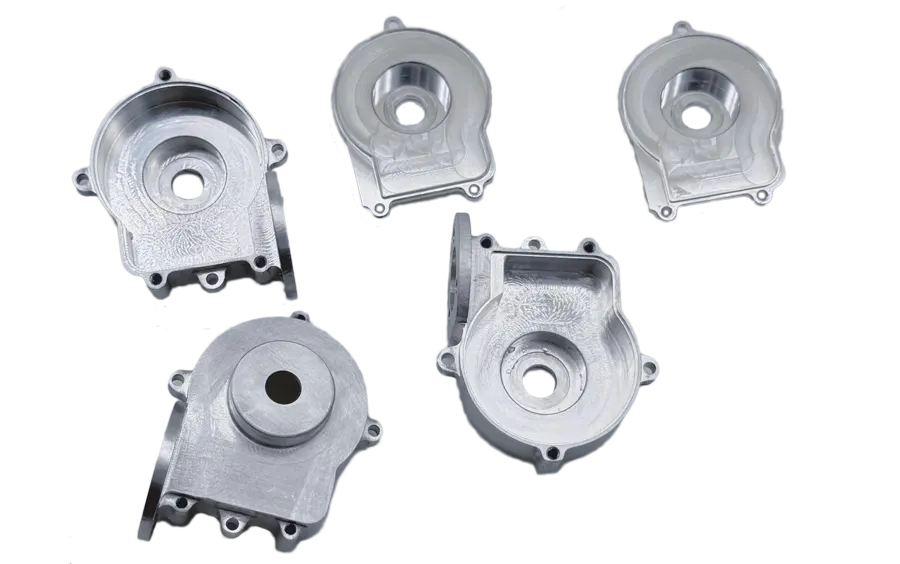

The part is left exactly as it comes straight off the machine tool, without any extra polishing, coating, or special finishing.

Example:

If you order a CNC aluminum part and choose As Machined, you’ll get a raw silver piece with visible cutter paths.

If you later want it to look nicer or resist corrosion, you can add treatments like anodizing, bead blasting, powder coating, etc.

Main Feature

Optimize your designs for manufacturability with our expert guidelines and feedback, ensuring the best results in CNC machining.

Advantages

- Cheapest option (no extra processing).

- Fastest turnaround.

- Good enough for functional prototypes or internal mechanical parts.

Disadvantages

- Not smooth or shiny.

- Lower corrosion resistance (no protective coating).

- May not be suitable for cosmetic or customer-facing parts.

Design Considerations for As Machined Parts

Our CNC systems deliver exact tolerances that satisfy sector norms, securing consistent accuracy and perfect piece fit.

Surface Roughness & Tool Marks

Tolerance vs. Finish Trade-off

Sharp Edges & Burrs

Material Choice Matters

No Extra Protection

Cost & Lead Time

Functional vs. Cosmetic Surfaces

If only certain areas of your part need a nice finish, you can:

FAQ about As Machined

To help you better understand our surface treatment capabilities, we’ve answered the most frequently asked questions.

“As Machined” refers to the surface finish of a part straight from the CNC machine, without any additional polishing, coating, or treatment. It typically shows fine tool marks and maintains the highest dimensional accuracy.

The standard “As Machined” finish usually offers a surface roughness of Ra 3.2 μm (125 μin), while high-precision machining can achieve Ra 1.6 μm (63 μin) without additional finishing processes.

“As Machined” is ideal for functional prototypes, tight-tolerance parts, or components where appearance is less critical than precision and cost efficiency.

Unlike anodizing, coating, or polishing, “As Machined” does not add protective or decorative layers. It prioritizes dimensional accuracy and machining efficiency, while other finishes improve aesthetics, corrosion resistance, or durability.

Yes. Since no secondary finishing is applied, slight tool paths and marks remain visible, but they do not affect the dimensional accuracy or performance of the part.

Most metals and plastics can be left “As Machined,” including aluminum, steel, stainless steel, brass, titanium, ABS, and POM. The machinability of the material influences the smoothness of the final surface.

No. “As Machined” surfaces provide the most accurate dimensional results since no material is removed after machining. This makes it ideal for high-precision applications.

Yes. Since no extra finishing steps are required, “As Machined” is the most economical option for prototypes and functional components where aesthetics or corrosion resistance is not a priority.

Absolutely. “As Machined” parts can undergo anodizing, plating, bead blasting, polishing, or painting later, depending on performance and appearance requirements.

“As Machined” parts are widely used in aerospace, automotive, robotics, medical devices, and industrial equipment—especially where tight tolerances and functional performance matter more than surface aesthetics.