Quality Assurance at Tonza's system

Utilizing advanced manufacturing processes, stringent quality assurance protocols, and strict compliance with industry standards, we guarantee exceptional quality, precision, and durability for your prototypes and on-demand production parts.

Our Quality Policy

Using advanced testing technology and equipment, we inspect dimensions, hardness, tensile strength, and elongation throughout production to ensure superior performance and customer satisfaction.

TonZa is dedicated to continuously improving and optimizing all aspects of custom manufacturing, from prototyping to production, along with the corresponding quality control processes, including CNC machining, rapid prototyping, and rapid tooling.

We adhere strictly to the ISO 9001-certified quality management system, following standardized production procedures and work instructions. Utilizing advanced testing equipment, we meticulously measure and inspect each stage of production to ensure your project meets the highest quality standards.

Click: ISO 9001:2015 Certification

Implement standardized and scientific management practices, develop efficient workflows and operating guidelines, cultivate highly skilled employees, and enhance production efficiency.

Driven by customer expectations and values, we continuously enhance our operations and management, including production planning, process optimization, supply chain coordination, cost control, and workforce quality. We strive for continuous improvement, excellence, and greater customer satisfaction.

By implementing a comprehensive quality management system, we strengthen quality control and inspections at every production stage, optimize company processes, and enhance communication between customers and departments. We also foster employee quality awareness, drive technological advancements, and ensure the efficient production of high-quality products.

By implementing a comprehensive quality management system, we reinforce quality control and inspections throughout production, optimize company processes, and enhance communication between customers and departments. Additionally, we cultivate employee quality awareness, drive continuous technological advancements, and ensure the efficient production of high-quality products.

Certifications & Quality Standards

Our CNC machines deliver precision tolerances that meet industry standards, ensuring consistent accuracy and seamless component fit.

We follow industry standard ISO 2768 tolerances.

TonZa is dedicated to continuously improving and optimizing all aspects of custom manufacturing, from prototyping to production, along with the corresponding quality control processes, including CNC machining, rapid prototyping, and rapid tooling.

We adhere strictly to the ISO 9001-certified quality management system, following standardized production procedures and work instructions.

Utilizing advanced testing equipment, we meticulously measure and inspect each stage of production to ensure your project meets the highest quality standards.

Quality Control Systems for Machine Shop

Utilizing state-of-the-art testing technology and advanced equipment, we conduct thorough inspections throughout the entire production process, measuring dimensions, hardness, tensile strength, and elongation of workpieces to guarantee superior performance and ultimate customer satisfaction.

Incoming Inspection

Purpose: Ensure that all raw materials and components meet quality standards before they enter the production process.

Process:

- Verification of material certificates and specifications.

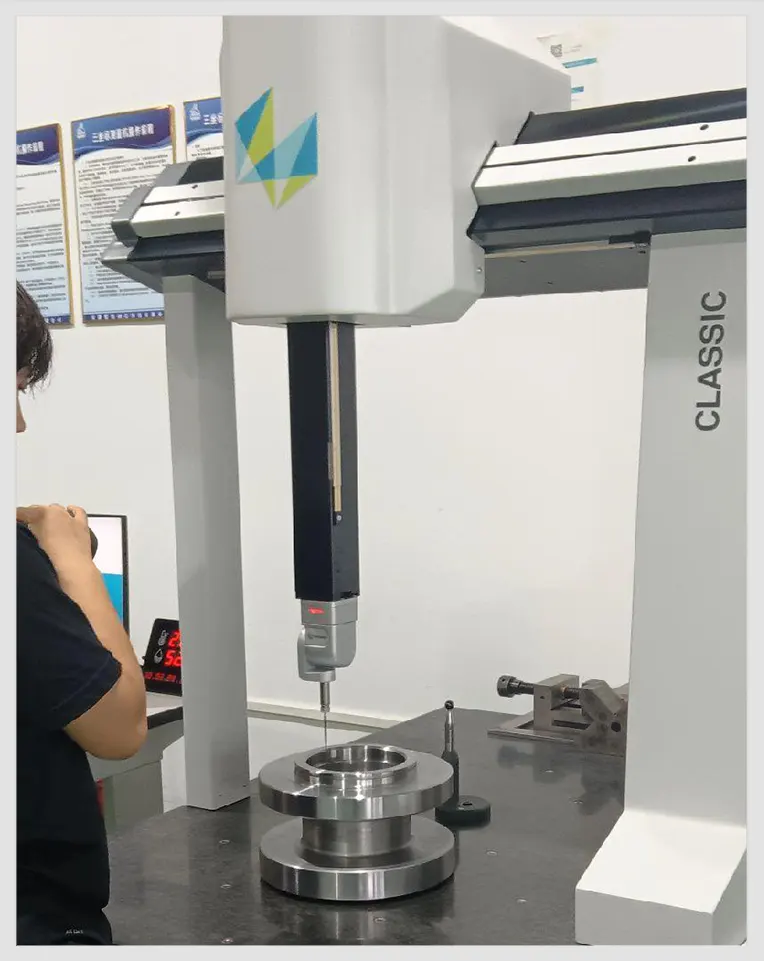

- Dimensional checks using precision instruments like calipers, micrometers, and CMMs .

- Visual inspection for any surface defects, rust, or contamination.

- Testing for material properties if required.

Outcome: Only compliant materials proceed to production, minimizing defects and rework.

In-process Inspection

Purpose: Monitor the machining process to ensure precision and consistency during production. We have professional quality engineer to charge it.

- Process:

- Regular checks at specific production stages to confirm dimensions, tolerances, and surface finish.

- Use of precision measuring tools like gauges, dial indicators, and optical comparators.

- Real-time monitoring for machine calibration and tool wear to maintain accuracy.

- Immediate feedback and corrective action for any deviations.

- Outcome: Early detection of errors, reducing waste and maintaining production efficiency.

Pre-Shipment Inspection

Purpose: Ensure that finished products meet customer specifications and quality standards before delivery.

- Process:

- Comprehensive dimensional and visual inspections on final products.

- Functional testing, if applicable, to verify its performance.

- Review of all documentation, including inspection reports, material certificates, and test results.

- Packaging inspection to prevent damage during transportation.

- Outcome: High-quality products delivered to customers, reducing the risk of returns or complaints.

Equipment

“Testing instruments play a crucial role in production, ensuring the manufacturing of high-quality products. Our facility features specialized workshops equipped with advanced technology, enabling comprehensive inspections and reinforcing our stringent quality control processes.”

Coordinate Measure Machine

High Performance 2D Image

Hardness Tester

Surface Roughness Tester

Impact Tester

Tensile Tester

| Item | Model | Brand | Accuracy | Qty | Period |

|---|---|---|---|---|---|

| 2D CMM | VMS-3020F | Ada | 0.005mm | 1 | 1 year |

| 2.5D CMM | CNC-4030AH | Ada | 0.005mm | 1 | 1 year |

| 3D CMM | CAPTUM 7/10/6 | Zeiss | 0.001mm | 1 | 1 year |

| 3D CMM | EXPERT 15108 | Leeder | 0.001mm | 1 | 1 year |

| 3D CMM | FLY1086 | Leeder | 0.001mm | 1 | 1 year |

| Semi-automatic altimeter | LH-600E/EG | Mitoyo | 0.001mm | 1 | 1 year |

| Semi-automatic altimeter | V4-400 | TRIMOS | 0.001mm | 1 | 1 year |

| High precision yaw meter | J2-D-200 | Azamara | 0.002mm | 1 | 1 year |

| Manual altimeter | 0-600mm | Mitoyo | 0.01 mm | 1 | 1 year |

| Cyindricity instrument | 1494x862x1685 | will | 0.001mm | 1 | 1 year |

| Vickers hardness tester | HV-1000 | Heng | 1 HRB | 1 | 1 year |

| Rockwell hardness tester | HR-150A | Dr. force | 2HRC | 1 | 1 year |

| Surfagage | 178-039 | Mitoyo | 0.01 Ra | 1 | 1 year |

Quality Control Procedures

“Our quality process is integrated into every stage of the project, from RFQs to final production and shipment.“

Quality Reports

“The quality inspection report reflects the results of rigorous product testing, ensuring compliance with relevant quality standards and safety requirements.”