3D Printing Materials

Current 3D printing materials primarily include metals, polymers, and ceramics, with plastics remaining the most widely used. That said, the use of metal materials is rapidly increasing, now accounting for approximately 36% of applications. The future of 3D printing largely depends on advancements in material development and effective market promotion.

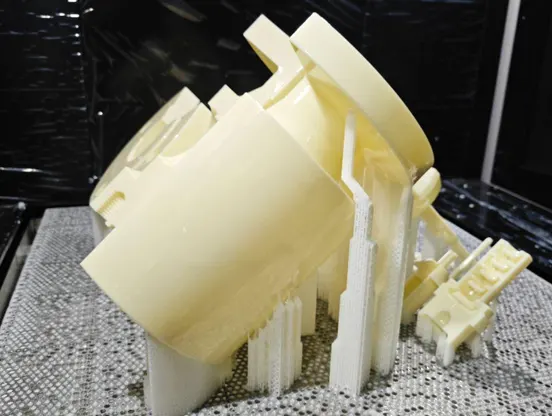

SLA Materials

SLA 3D printing primarily uses powdered materials, which are sintered layer by layer using a laser. The most common materials include:

| Type | Color | Temperature resistance | Paintable | Hardness | Viscosity cps( 25 ℃) | Density g/cm3(25℃) | Layer Height (mm) | Bending Strength (Mpa) | Tensile Strength (Mpa) |

|---|---|---|---|---|---|---|---|---|---|

| JS-UV-HP-02 | White | 30℃ – 40℃ | Y | 76-85 | 360-420 | 1.11-1.14 | 0.05-0.12 | 60-75 | 25-30 |

| JS-UV-2016-XLST | Yellow | 30℃ – 40℃ | Y | 76-85 | 360-400 | 1.11-1.14 | 0.05-0.12 | 60-75 | 25-30 |

| Black Resin | Black | 30℃ – 40℃ | Y | 76-85 | 360-400 | 1.11-1.14 | 0.05-0.12 | 60-75 | 25-30 |

| Translucent Resin | Colorless | 30℃ – 40℃ | Y | Hazy feeling, the surface texture is similar to that of white resin | |||||

SLS Materials

SLS 3D printing primarily uses powdered materials, which are sintered layer by layer using a laser. The most common materials include:

| Type | Color | Temperature resistance | Paintable | Specifications |

|---|---|---|---|---|

| PA12 Black | Ash Black | 100℃ | N | Stable color Accurae size High reusability |

| PA12 White | Bright White | 100℃ | N | Stable color Accurae size High reusability |

| PA12 30% GF | Grayish Yellow | 100℃ | N | High strength Heat deformation resistance High reusability 30% glass |

| PA12 40% Alu | Metallic Grey | 100℃ | N | High strength Wear resistance Metal color High reusability 40% aluminum powder |

FDM Materials

Zinc alloys are widely used in high-pressure die casting (HPDC) due to their high strength, excellent wear resistance, dimensional stability, and ability to form intricate shapes with fine details. They also offer good corrosion resistance, low melting points (less energy needed), and long mold life.

| Type | Color | Tensile Strength (Mpa) | Elongation at Break (%) | Tempature Resistancce (°C) |

|---|---|---|---|---|

| ABS-M30 | Black, Dark Grey, Ivory, White | 32 -28 | 7-2 | 96 |

| ABSi | Translucent | 37 | 4.4 | 86 |

| ASA | Black, Gray, Green, Ivory, White | 27 | 9-3 | 98 |

| Nylon 12 | Black | 49.3 -41.8 | 30-6.5 | 91.9 |

| PC-ABS | Black | 41 | 6 | 110 |

| PC | White | 57 -42 | 4.8-2.5 | 138 |

| PC-transparent | Translucent Natural, White | 57 | 4 | 133 |

| PLA | Black, White | 50 -37 | 2.9-1.9 | 55 |

| ULTEM 9085 | Black, Tan | 47 -33 | 5.8-2.2 | 153 |

| ULTEM 1010 | Amber (Natural) | 64 -41 | 3.3-2.0 | 216 |

MJF Materials

Copper alloys are used in high-pressure die casting (HPDC) due to their excellent thermal and electrical conductivity, high strength, corrosion resistance, and wear resistance. These alloys are commonly used in electrical, plumbing, marine, automotive, and industrial applications where durability and conductivity are essential.

| Type | Color | Tensile Strength (MPA) | Elongation at Break (%) | Tempature Resistancce (°C) |

|---|---|---|---|---|

| PA11 | Black, Grey | 52 | 50 | 54 |

| PA12 | Black, Grey | 48 | 20 | 92 |

| PA12 GB 40 | Black, Grey | 30 | 6.5 | 120 |

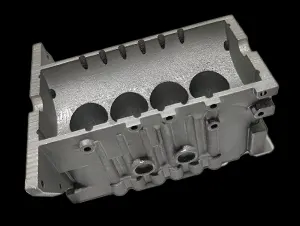

SLM Materials

Copper alloys are used in high-pressure die casting (HPDC) due to their excellent thermal and electrical conductivity, high strength, corrosion resistance, and wear resistance. These alloys are commonly used in electrical, plumbing, marine, automotive, and industrial applications where durability and conductivity are essential.

| Type | Density (g/cm3) | Tensile Strength (MPa) | Elongation after break (%) | Vickers Hardness (%) | Features |

|---|---|---|---|---|---|

| Stainless Steel-316L | ≥7.90 | 480-580 | ≥40 % | ≥180 | High Hardness and Toughness Strong corrosion resistance better machinability Can be high gloss polished |

| Nickel-Chromium-In 718 | ≥8.18 | 1230-1430 | 12%-20% | ≥410 | Ease of processing It has high Tensile Strength, fatigue strength, Creep strength and breaking strength High oxidation resistance at 1000°C Stable chemical properties at low temperatures Good welding performance, strong corrosion resistance |

| Cobalt Chromium-CoCr | ≥8.35 | 980-1080 | 7%-10% | ≥350 | Excellent finished surface high toughness high strength Excellent biocompatibility good corrosion resistance |

| Aluminum alloy-AlSi10Mg | ≥2.65 | 400-460 | ≥5 % | ≥120 | Build parts with excellent mechanical properties, Such as Hardness and Tensile Strength excellent corrosion resistance Good thermal and electrical conductivity High dynamic toughness |

| Titanium alloy-TC4 | ≥4.40 | 1050-1150 | 4%-8% | ≥310 | High strength to mass ratio Strong corrosion resistance Good biocompatibility and osseointegration Small thermal expansion, low thermal conductivity better machinability |

| Tin Bronze alloy-CuSn10 | ≥8.78 | 460-520 | ≥20 % | ≥115 | Seawater cavitation resistance, good corrosion resistance Good wear resistance better machinability Good thermal conductivity non-magnetic |

How to Choose?

Selecting the right plastic for 3D printing depends on several key factors, including mechanical properties, environmental resistance, and application requirements. Here are some important considerations:

1. Consider the Application Requirements

Ask these questions to determine the best material:

- Strength & Durability – Does the part need to withstand heavy loads or impact?

- Flexibility – Does the part need to be bendable or elastic?

- Heat Resistance – Will the part be exposed to high temperatures?

- Surface Finish & Detail – Does the part need a smooth or detailed finish?

- Chemical & UV Resistance – Will it be used outdoors or in harsh environments?

- Biocompatibility – Is it for medical use or skin contact?

| 3D Printing Technology | Compatible Materials | Best For |

|---|---|---|

| Fused Deposition Modeling (FDM) | PLA, ABS, PETG, TPU, Nylon | Prototyping, functional parts, low-cost production |

| Stereolithography (SLA) / Digital Light Processing (DLP) | Standard resins, tough resins, flexible resins, castable resins | High-detail prototypes, jewelry, dental, medical |

| Selective Laser Sintering (SLS) | Nylon (PA12, PA11), TPU, Polypropylene (PP) | Functional parts, flexible parts, wear-resistant applications |

| Multi Jet Fusion (MJF) | Nylon (PA12, PA11), TPU | High-strength industrial parts, automotive, medical |

| Direct Metal Laser Sintering (DMLS) / Selective Laser Melting (SLM) | Aluminum, Titanium, Stainless Steel, Copper | Aerospace, automotive, medical implants |

| Material | Properties | Best For |

|---|---|---|

| PLA (Polylactic Acid) | Easy to print, biodegradable, low strength | Prototyping, hobbyist printing |

| ABS (Acrylonitrile Butadiene Styrene) | Strong, heat-resistant, slightly flexible | Functional parts, automotive, enclosures |

| PETG (Polyethylene Terephthalate Glycol) | Strong, impact-resistant, chemical-resistant | Food containers, medical applications |

| TPU (Thermoplastic Polyurethane) | Flexible, rubber-like, durable | Wearables, grips, seals |

| Nylon (PA12, PA11) | High strength, wear-resistant, flexible | Industrial parts, gears, hinges |