ensure cost-effective fabrication tailored to your needs.

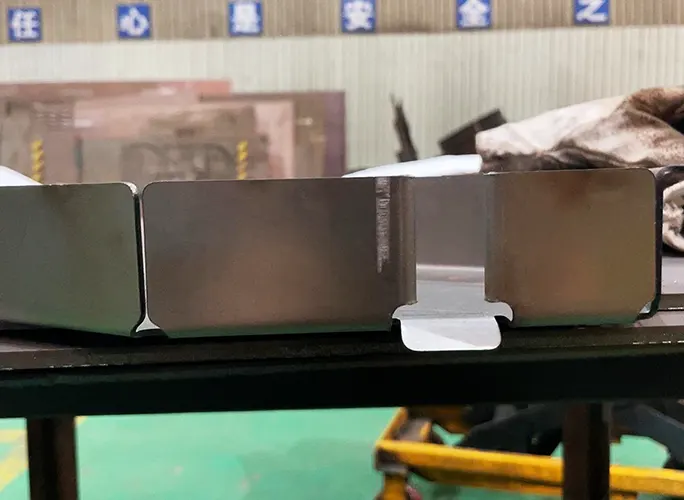

Online Sheet Metal Fabrication Service

We provide expert sheet metal fabrication services, specializing in cutting, bending, welding, and assembly for high-quality metal components.

- Our in-house machine shop operates 24/7, ensuring quick turnaround times.

- Typical leading time 3 days.

Custom Parts

TonZa offers fast and cost-effective sheet metal fabrication services, including a free DFM report and expert engineering advice. We specialize in sheet metal cutting, bending, welding, and assembly for a wide range of projects.

Laser Cutting

Plasma Cutting

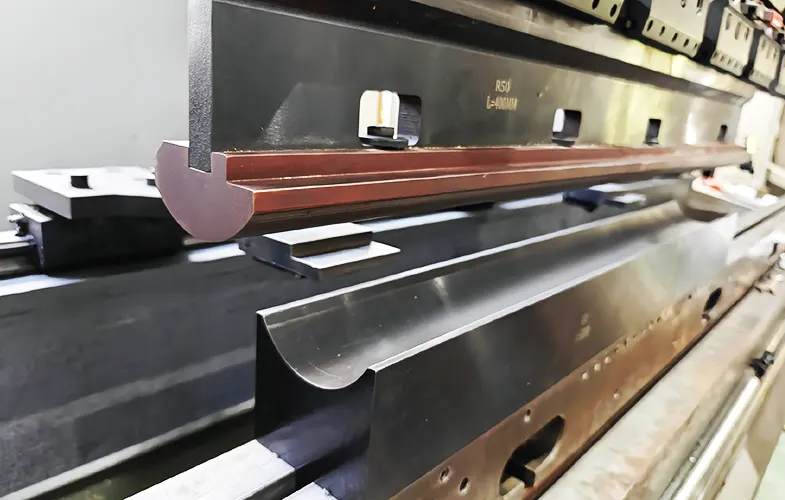

Bending

Stamping

Punching

Welding

Why Choose ours Sheet Meatal Fabrication Services?

delivering exceptional results through experience, dedication, and strategic thinking.

working closely with clients to understand their unique needs and goals

featuring the latest technology and advanced machinery to ensure precision, efficiency.

leveraging cutting-edge technology to manufacture intricate components

delivering exceptional value without compromising on quality or precision.

ensuring fast, efficient, and reliable production without compromising quality.

Capabilities of Sheet Meatal Fabrication Services

Our sheet metal fabrication service meets industry-standard precision tolerances, ensuring consistent accuracy and a flawless component fit.

Maximum Diameter: 500mm or 19.7-inch

Maximum Length: 1800mm or 70.9-inch

Metal: 0.5mm or 0.02 in

Plastic: 1.0mm or 0.04 in

Metal: +/- 0.005mm (+/-0.0002 in)

Plastic: +/-0.025mm(+/-0.001 in)

4 bussiness days for most projects.

simple parts can be as fast as 1 day.

Design Guidelines

Optimize your designs for manufacturability with our expert guidelines and feedback, ensuring the best results in Sheet Meatal Fabrication.

Bend Design

2. Avoid sharp bends: Use internal radii to reduce material stress..

3. Bend relief: Provide relief cuts to prevent tearing in tight bends.

Hole Placement and Size

2. Hole edge distance: Maintain a gap of ≥ 2× sheet thickness from edges or bends..

3. Standard hole sizes: Use standard drill bit sizes to minimize custom tooling costs.

Cutout and Slot Design

2. Corner radii for cutouts: Use R ≥ 0.5 mm to reduce stress concentration..

3. Tab and notch clearance: Maintain a minimum gap of ≥ 1 mm for clean cutting.

Tolerances

2. Bending tolerance: ±0.5 mm (depends on material and thickness).

3. Hole placement tolerance: ±0.1 mm for laser cutting.

Flange and Hemming Guidelines

2. Hemming: Used to reinforce edges, reduce sharpness, and improve strength..

3. Hemming gap: Maintain a 0.5 mm clearance for tightly closed hems..

Welding and Joining Considerations

2. Spot welding vs. full welding: Spot welding is faster and preferred for thin sheets.

2. Leave access for welding tools: Ensure joints are easily reachable..

Surface Finishing

2. Anodizing: Corrosion resistance for aluminum..

3. Plating & painting: Additional aesthetic and protective options..

Nesting and Material Utilization

2. Use standard sheet sizes to reduce cutting complexity and cost.

3. Reduce small, intricate features that may be difficult to fabricate..

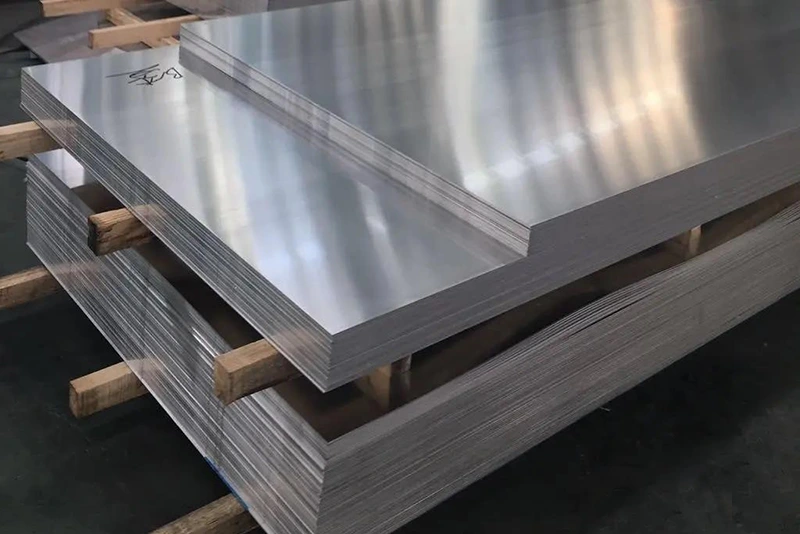

Materials for Sheet Metal Fabrication

Select from a variety of sheet metal materials, including aluminum, stainless steel, and brass. Each material is carefully chosen for its unique properties, enabling us to recommend the ideal option for your project’s specific needs and applications.

Aluminum

Typically models: A2024, A2052, A5052, A5754, A6061, A6063, A7075, etc.

Stainless Steel

SUS304 (18-8 stainless steel, non-magnetic), SUS301 (spring stainless steel, slightly magnetic), SUS430 (magnetic, easier to rust)

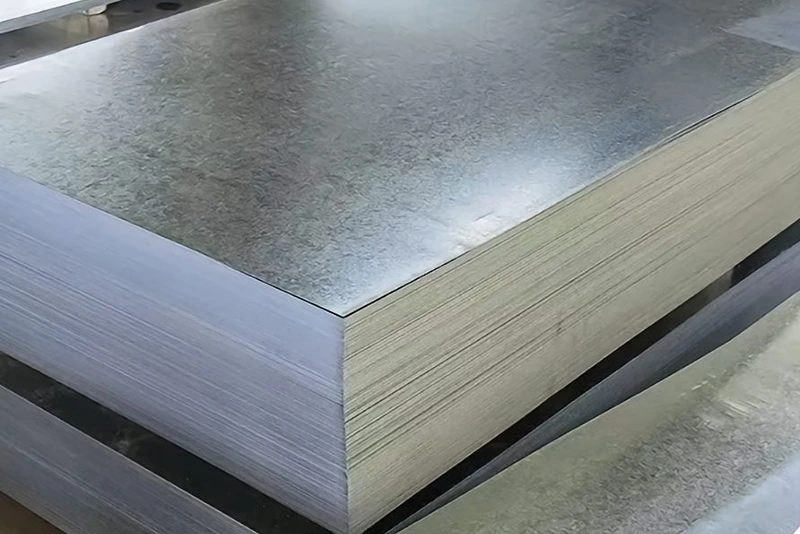

Cold Rolled Sheets

SPCC, CRS, SPCD, SPCE.

Hot Rolled Sheets

SPHC, HRS

Hot-dip galvanization Sheet

Zn100-PT, Zn200-SC, Zn275-JY (GB/T 2518-2008)

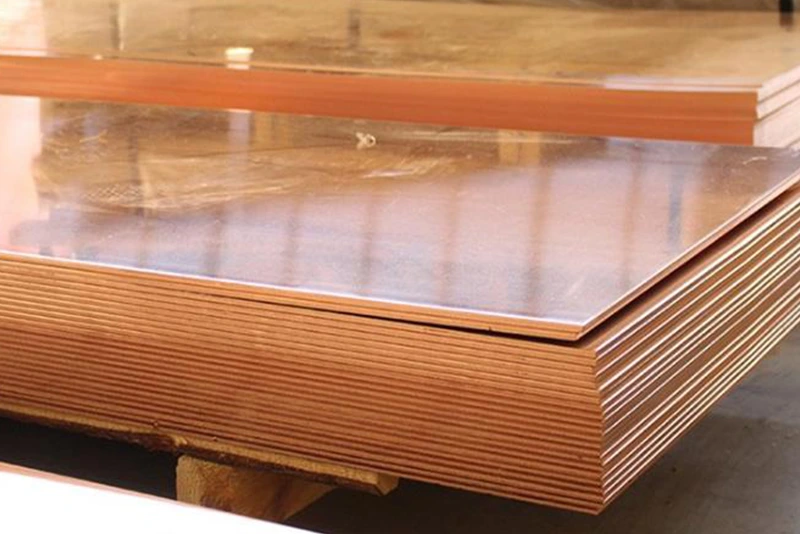

Copper

C1020, C1100 C2100, 2200, 2300, 2400, C2600 and above for red copper (purple copper), T2-Y purple copper plate

Surface Finishes

We are offering over 20 options of surface finishes to fulfill both your functional and aesthetic requirements.

Brushing

Sand Blast

Polishing

Tumbling

Anodizing

Painting

Black Oxide

Electroplating

Powder Coating

Alodine

Passivation

Electroless Plating

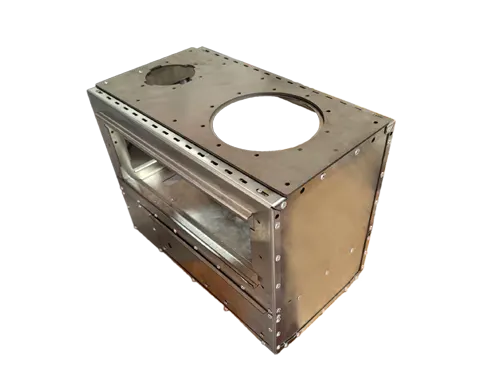

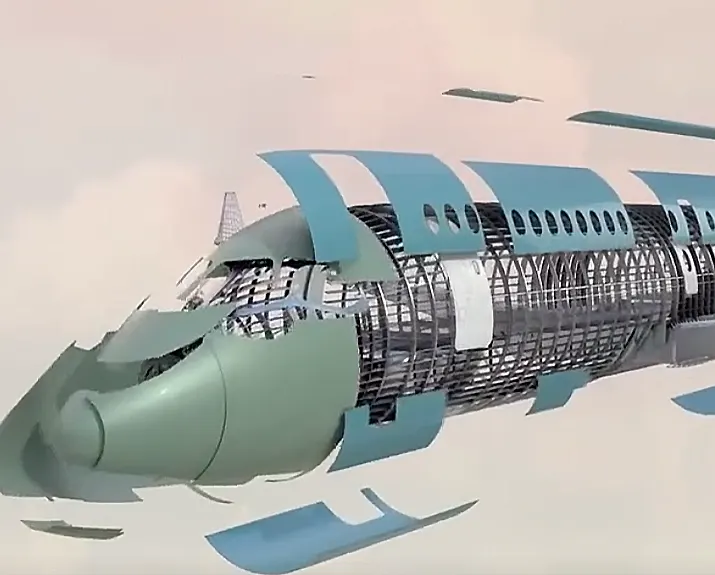

Applications

Sheet metal fabrication produces a variety of parts and components, each tailored to meet specific functional and aesthetic requirements.

Automotive

- Body panels (hoods, doors, fenders)

- Chassis components

- Exhaust systems

- Heat shields

- Battery enclosures

Aerospace

- Aircraft fuselage sections

- Wing panels

- Engine mounts

- Brackets and supports

- Exhaust ducts

Electronic

- Server racks

- Electrical boxes

- Control panels

- Switchgear enclosures

- Cable trays

Industrial Machinery

- Gear covers

- Mounting brackets

- Machine guards

- Conveyor system components

Medical

- Medical device enclosures

- Instrument panels

- Surgical trays

- Cart frames

Military and Defense

- Armored vehicle panels

- Weapon casings

- Drone frames

- Tactical equipment enclosures

FAQ

We provide SPI surface finishes for injection-molded parts. Our experts are ready to help you select the ideal finish for your project.

We provide laser cutting, CNC punching, bending, welding, stamping, and finishing services for various industries.

We work with stainless steel, aluminum, carbon steel, galvanized steel, brass, and other custom materials based on your project requirements.

Yes, we specialize in custom sheet metal fabrication and rapid prototyping to meet your specific needs.

Standard lead times range from 7 to 25 days, depending on project complexity and order quantity.

Yes, we offer powder coating, anodizing, electroplating, painting, brushing, and other surface treatments.

We accept DXF, DWG, STEP, IGES, and PDF files. If you need assistance, our engineers can help with design modifications.

Yes, we support both low-volume custom projects and high-volume production runs.

We follow strict quality control measures, including material inspection, dimensional checks, and final product testing before shipment.

We accept T/T, PayPal, and L/C payments. Shipping is available via air, sea, or express courier (DHL, FedEx, UPS).

Yes, we offer full OEM and ODM services, including private labeling and custom branding.

Would you like me to refine or add any more details based on your specific services?

Blog

Welcome to our blog, where we share insights into various manufacturing processes.