Order your custom plastic parts.

Online Overmolding service

Get custom plastic prototypes and durable production parts—request your free overmolding quote today!

- Get free and automatic DFM feedback.

- Typically injection molding: 3 days

- T1 sample as fast as 2 weeks

What is Overmolding?

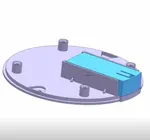

Plastic overmolding joins two or more materials into one product. This method makes items stronger, better looking, and more useful. For instance, it improves grip on tools and shields surfaces from water and rust, which helps products last longer. Many industries use overmolding to make smarter designs and fix production problems, including metal machining.

Why Choose ours Overmolding Service?

Test over 200 material pairings with comprehensive compatibility reports delivered.

Maintain ±0.5°C temperature control to eliminate flash and ensure consistent quality

Receive wall thickness optimization and design tips within 48 hours.

Automatically adjusts pressure in-process to prevent sink marks and defects.

Achieve <0.02mm alignment accuracy between base and overmold for flawless integration.

Seamless finishes ideal for electronics and medical-grade components.

Materials for Injection Overmolding

Overmolding technology represents a breakthrough in multi-material integrated manufacturing, offering a wide range of material pairing possibilities to meet diverse industrial needs.

At Tonza, we categorize these material combination strategies into three key approaches:

Fast delivery

Functional Synergy

Example: Combining polypropylene (PP) with SEBS elastomers enables molecular chain entanglement, eliminating the need for bonding agents. This pairing also withstands gamma sterilization up to 25kGy, making it ideal for medical-grade handles and sterile applications.

Short lead time

Performance Enhancement

Example: Nylon (PA66) overmolded with TPV elastomers creates components with outstanding oil and acid resistance and ultra-low friction (μ = 1.2). This combination is perfectly suited for high-voltage battery housings in electric vehicles, where chemical durability and smooth operation are essential.

High Quality

Sustainable Innovation

Example: Merging bio-based TPE with PLA (polylactic acid) substrates delivers fully biodegradable products. This approach reduces carbon emissions by up to 50% and complies with EN 13432 standards for industrial compostability—transforming the future of eco-friendly packaging systems.

| Substrate | Overmold | Typical Applications | Certification Standards |

|---|---|---|---|

| ABS | TPE, TPU, SEBS | Tool handles, consumer electronics, appliance grips | RoHS, REACH, UL94 HB or V-0, FDA (for food-grade TPE) |

| PC | TPE, TPU | Power tool housings, phone cases, protective gear | UL94 V-0, RoHS, REACH, FDA (medical grade TPU) |

| PP | TPE (PP-based) | Toothbrush grips, personal care products, seals | FDA (food/skin contact), RoHS, REACH |

| PA (Nylon) | TPU, TPE | Automotive parts, cable connectors, industrial tools | ISO 9001, IATF 16949 (auto), UL94 V-0, RoHS |

| PBT | TPU, TPE | Electrical connectors, automotive clips, sensors | UL94 V-0, ISO 11469, RoHS, IEC 60335 |

| PC/ABS | TPE, TPU | Consumer electronics, wearables, medical housings | RoHS, REACH, ISO 10993 (biocompatibility) |

| Metal | TPE, TPU, Silicone | Smartwatch bands, surgical instruments, hybrid assemblies | ISO 13485 (medical), REACH, FDA (if applicable) |

Overmolding vs. Insert Molding vs. Two-color Molding

Overmolding, Insert Molding, and Two-color Molding—are often used for multi-material or multi-functional parts, but they differ significantly in process, application, and tooling.

| Aspect | Overmolding | Insert Molding | Two-color Molding (2K Molding) |

|---|---|---|---|

| Definition | Molding a soft or secondary material over a rigid substrate | Placing pre-made components (e.g., metal) into mold, then molding plastic around them | Simultaneously molding two different materials/colors using a dual-injection machine |

| Materials Involved | Typically two different thermoplastics (e.g., TPE on PC) | Metal + plastic, or plastic + plastic | Two thermoplastics with good bonding compatibility |

| Process Type | Sequential — substrate molded first, then overmolded | Inserts manually or robotically placed before injection | Simultaneous injection via dual-barrel machine |

| Tooling | Two molds or one mold with multiple stages | Standard mold with insert-holding capability | Specialized dual-shot mold with rotary or sliding mechanism |

| Adhesion Method | Thermal, chemical, or mechanical bonding | Mechanical interlocking or bonding | Strong chemical and thermal bond during co-injection |

| Strength | Moderate to strong, depends on material compatibility | Strong mechanical bond | Excellent due to simultaneous fusion |

| Applications | Soft grips, seals, medical tools, electronic enclosures | Metal-plastic assemblies, threaded inserts, connectors | Dual-color buttons, toothbrush handles, aesthetic housings |

| Cycle Time | Medium — two-shot process with cooling time | Slower — manual or robotic insert placement | Fast — done in a single cycle with specialized machine |

| Cost | Moderate — requires secondary molding step | Lower tooling cost, but longer cycle times | Higher initial tooling and machine cost, lower unit cost |

| Bonding Risk | Depends on material compatibility and process control | High bonding strength due to mechanical fit | Very low — materials fuse in molten state |

FAQ

We provide high-precision plastic overmolding services that ensure seamless bonding, enhanced durability, and a perfect fit for complex multi-material parts.

Overmolding improves grip, durability, vibration resistance, aesthetics, and eliminates the need for adhesives or secondary assembly steps.

Common materials include ABS, PC, PA, TPE, TPU, and PP. Compatibility between substrate and overmold is crucial for proper bonding.

Overmolding is widely used in electronics, medical devices, automotive, consumer products, and industrial equipment.

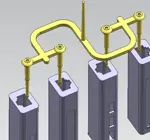

Yes, metal inserts or components can be overmolded with plastic to add functionality or comfort, such as in tools or connectors.

Insert molding involves placing a pre-formed component (often metal) into the mold before injecting plastic, while overmolding involves molding one plastic over another plastic or material.

When materials are properly selected and processed, the bond is very strong and often resistant to peeling, moisture, and mechanical stress.

Wall thickness, draft angles, undercuts, venting, and material compatibility are key. We offer DFM reviews to help optimize your part design.

We typically maintain tight tolerances, including mold positioning errors as low as <0.02mm, depending on part geometry and material behavior.

Lead times vary by project complexity, but rapid tooling and fast DFM reviews allow us to deliver overmolded parts in as little as 1–3 weeks.